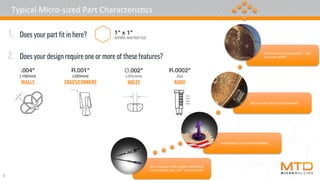

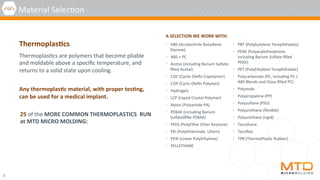

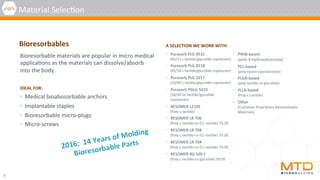

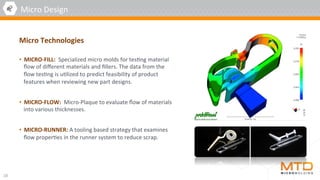

The document outlines a webinar focused on medical micro molding, featuring experts discussing the challenges and solutions in micromolding for medical applications. It highlights the capabilities of MTD Micro Molding, including material selection, production techniques, and case studies demonstrating successful applications in the industry. The session also emphasizes the importance of advanced technologies and methodologies for achieving high precision and quality in micro medical devices.

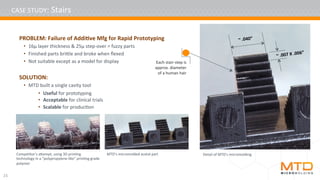

![• Model vs. Molded part

• Iden4fy failure modes (PFMEA)

• Prototype-bridge tooling – high cavita4on produc4on

• Son tooling vs. Hard tooling

• Exact execu4on with work piece accuracy of:

.000042” [~ 1µ, 0.0010668 mm]

• Sarix 3D EDM milling

• All maintenance performed in-house

• EOAT in-house – Automa4on

11

Micro-Edge Tooling

Micro Tooling](https://image.slidesharecdn.com/2016-04-07nicmdo-160405130120/85/Challenges-Emerging-Solutions-through-Micro-Molding-11-320.jpg)

![• Reviewing what is possible

<R.001”

.002” wall thicknesses

250:1 aspect ra5os

Zero dra]

• Micro Medical Applica4ons:

Endoscopy

Laparoscopy

Abla5on

Brachytherapy

Drug Delivery

Fixa5on

14

Micromolding Opportuni4es

Material: 30% GF Nylon 12

Challenge: U4lize the micro molding process to insure a polymer rich

surface which would not allow a possible electrical leak path as well shut

off on delicate wiring ranging from .010” up to .015”. Handling 6-8 n of

delicate wire assembly.

Descrip5on: Electrocautery device used in a new laparoscopic platorm.](https://image.slidesharecdn.com/2016-04-07nicmdo-160405130120/85/Challenges-Emerging-Solutions-through-Micro-Molding-14-320.jpg)