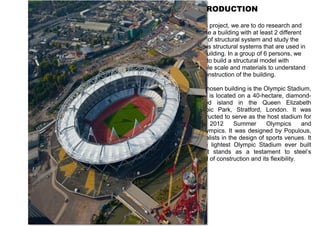

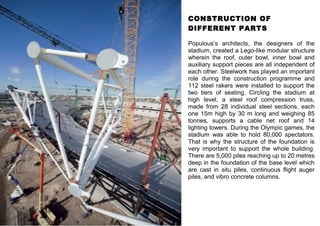

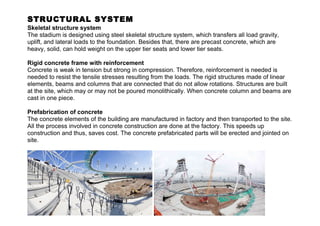

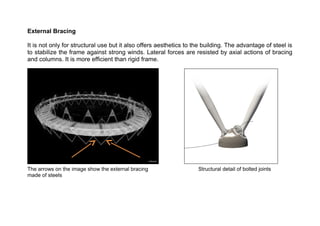

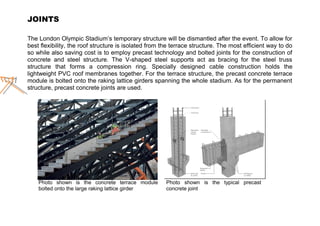

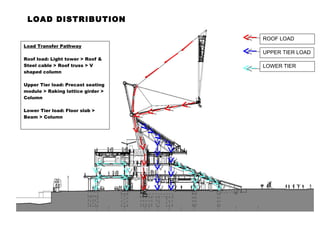

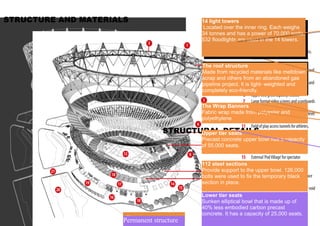

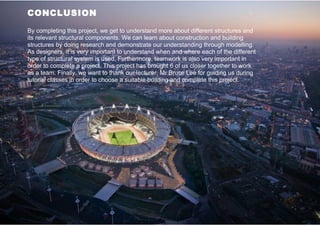

The document discusses the structural systems used in the Olympic Stadium built for the 2012 London Olympics. The stadium features several different structural systems, including a steel skeletal structure, rigid concrete frames with reinforcement, and prefabricated concrete. It also uses external steel bracing and bolted joints between elements. The steel structure supports the cable net roof and transfers loads through the various structural elements to the foundation of 5,000 piles. The document provides details on the different structural components and materials used to construct the lightweight and efficient stadium structure.

![SCHOOL OF ARCHITECTURE, BUILDING & DESIGN

Bachelor of Science (Honours) in Architecture

BUILDING CONSTRUCTION 2 [ARC 2513]

Project 2: Understanding Forces in Solid Structure and Surface Structure

Tutor: Mr Bruce Lee Xia Sheng

GROUP MEMBERS: TAN WEI HOW (0310707)

YONG CHANG THENG (0310925)

LEE YUAN JUNE (0311128)

WONG PEAKKY (1101A13474)

CHUAH WEI HONG (0310900)

CHEONG SIEW LEONG (0310845)](https://image.slidesharecdn.com/b-141208130624-conversion-gate01/85/Building-Construction-2-Project-2-Report-2-320.jpg)

![REFERENCES

1. London 2012 - Olympic Stadium, 2012, Detail architecture-topics.

[online] Available at:

http://www.detail-online.com/architecture/topics/london-2012-olympic-stadium-019389.html

2. Olympic Stadium, London, 2012, Structural Steel Design Awards, Steel Construction.

[online] Available at:

http://www.steelconstruction.info/Olympic_Stadium,_London

3. How to Construct the Lightest, Most Open Olympic Stadium Ever built, 2012, Popular

Science.

[online] Available at: http://www.popsci.com/technology/article/2012-07/how-construct-lightest-

most-open-olympic-stadium-ever-built

4. London 2012 Olympic Stadium, 2014, Designing Buildings Wiki.

[online] Available at:

http://www.designingbuildings.co.uk/wiki/London_2012_Olympic_Stadium#Engineering_for_t

he_Seating_Bowl](https://image.slidesharecdn.com/b-141208130624-conversion-gate01/85/Building-Construction-2-Project-2-Report-15-320.jpg)