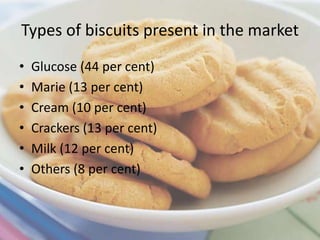

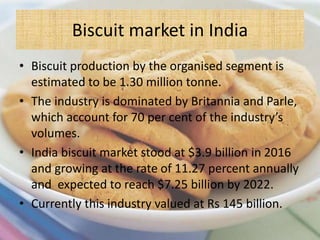

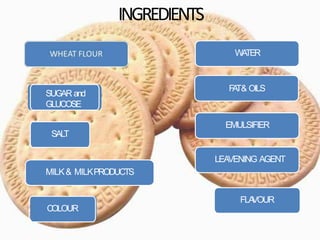

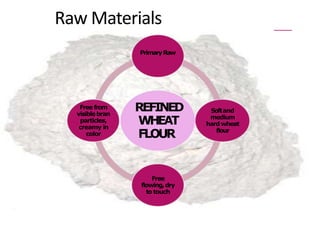

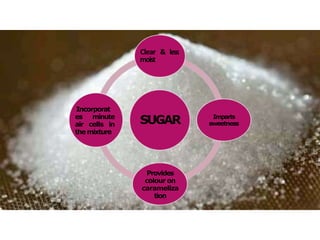

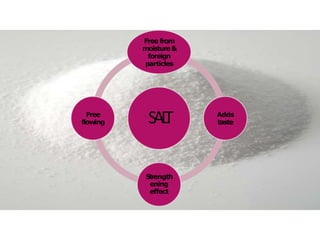

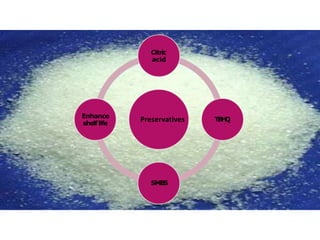

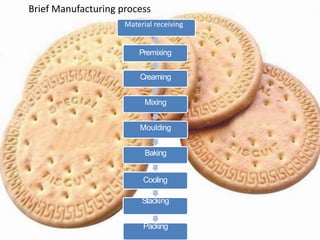

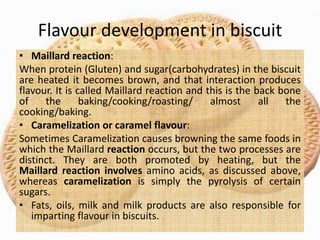

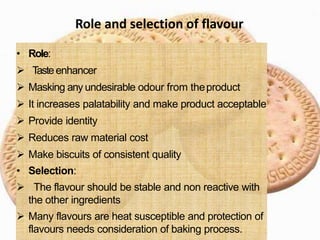

This document discusses the manufacturing process for glucose biscuits in India. It begins by introducing different types of biscuits produced in India, with glucose biscuits making up 44% of the market. It then provides an overview of the key ingredients in biscuit production like flour, sugar, fats, milk, water, salt, and leavening agents. The document outlines the basic biscuit manufacturing process of premixing, creaming, mixing, moulding, baking, cooling, stacking, and packing. It also discusses how maillard reactions and caramelization impact flavor development in biscuits during baking.