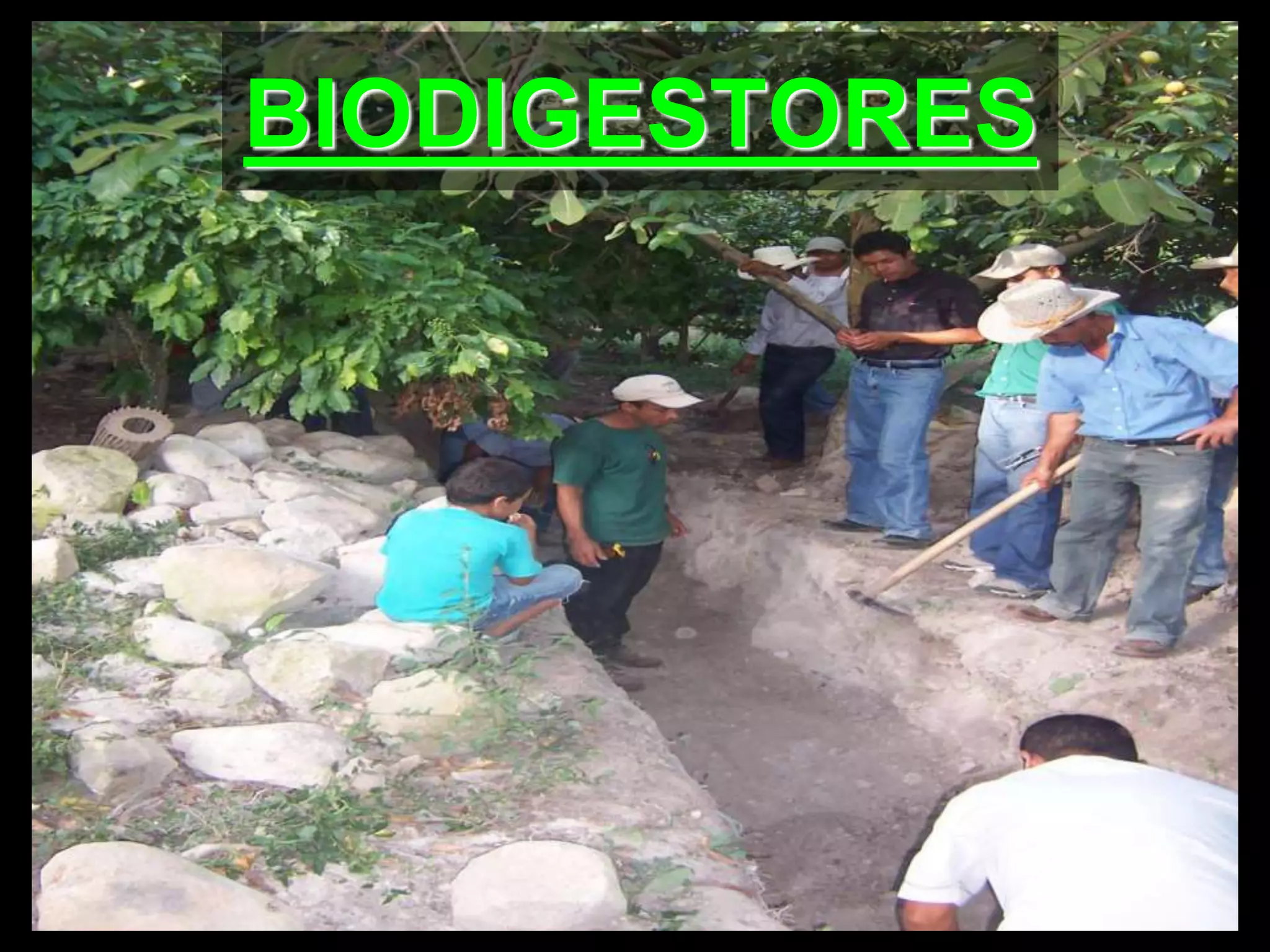

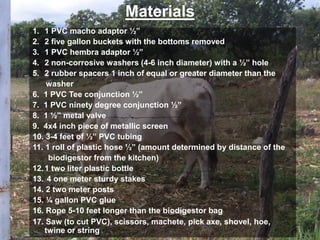

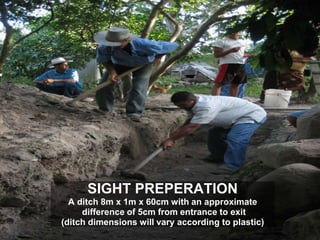

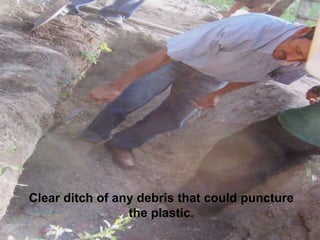

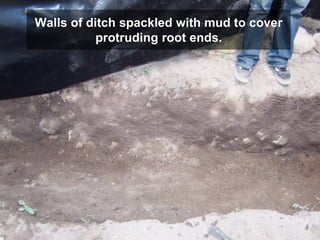

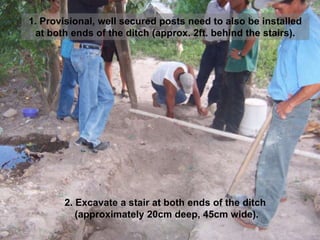

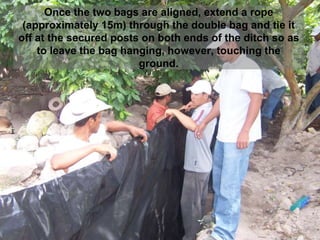

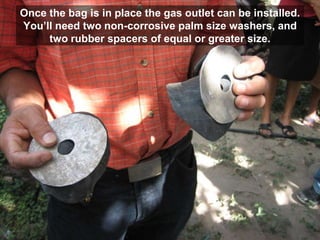

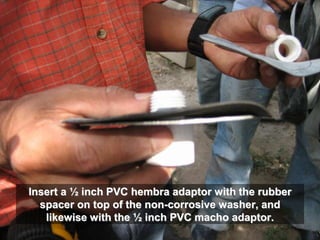

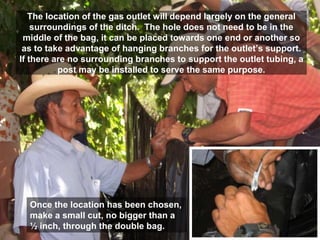

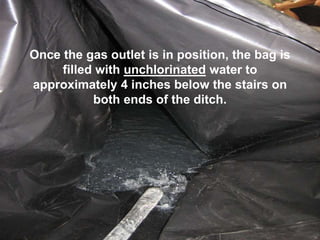

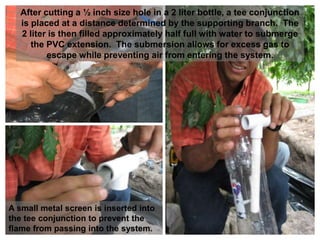

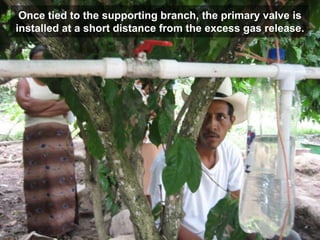

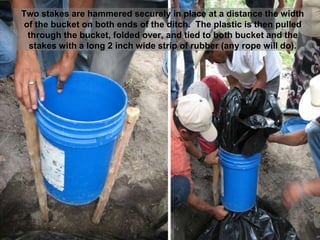

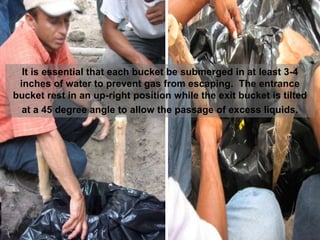

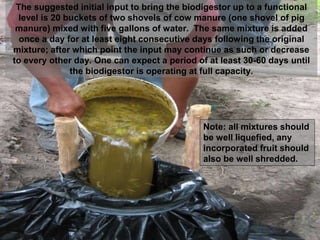

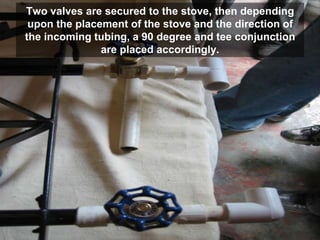

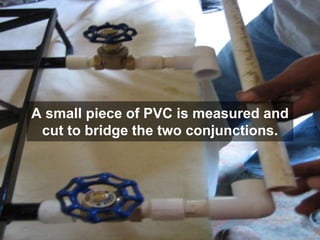

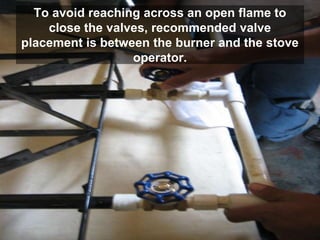

This document provides instructions for building a biodigester system to produce biogas from food and animal waste. It details the necessary materials which include PVC piping, buckets, tubing, and stakes. Steps include digging a trench, lining it with plastic, installing gas outlets and valves, filling it with water and initial inputs of manure and water. Regular daily inputs are recommended to get the system functioning properly within 30-60 days, producing biogas that can be piped to a kitchen stove for cooking fuel.