1) This document discusses allowable stress design (ASD) based on the 1989 AISC specification for structural steel design. It compares ASD to load and resistance factor design (LRFD) and outlines the key differences between the two approaches.

2) Formulas and examples are provided for calculating allowable stresses in tension members based on yielding and fracture, as well as for calculating allowable stresses in compression members based on buckling strength.

3) The document notes that while the AISC Manual still references the older ASD approach, the specification has been updated to the LRFD method, and engineers should follow the specification over the manual.

![NPIC

Appendix B. karKNnaeRKOgbgÁúMEdkedayQrelIkugRtaMgGnuBaØat

Structural Steel Design Based on Allowable Stress

B >1> esckþIepþIm Introduction

PaBxusKñacMbgrvag allowable stress design nig loads and resistance factor design

KWemKuNsuvtßiPaB. * enAkñúg LRFD eKGnuvtþemKuNbnÞúkeTAelIbnÞúk nigemKuNersIusþg;eTAelIersIusþg;.

elIsBIenH tMélrbs;emKuNbnÞúkGaRs½ynwgRbePTrbs;bnÞúk nigkarbnSMbnÞúk. enAkñúg allowable

stress design (ASD) eKeRbIEtemKuNsuvtßiPaBmYyKt; ehIyvaRtUv)anGnuvtþeTAelIkugRtaMgEdl

manenAkñúgsßanPaBkMNt;. sßanPaBkMNt;rbs; ASD KWRsedogKñasMrab; LEFD KW yielding, fraturee

nig buckling. eKalkarN_rbs;allozable stress analysis and design KWmandUcteTA³

kugRtaMgenAkñúgsßanPaBkMNt;RtUv)anEckCamYynwgemKuNsuvtßiPaBedIm,ITTYl)ankugRtaMgGnuBaØat

ehIykugRtaMgGb,brmaEdlekIteLIgeday service load dac;xatminRtUvFMCagkugRtaMgGnuBaØatenH

eT. ]TahrN_ sMrab;kMlaMgTajtamG½kS

P

ft = ≤ Ft (B.1)

A

Edl kugRtaMgTajKNna

ft =

P = bnÞúkTajtamG½kSeFVIkar

Ft = kugRtaMgTajGnuBaØt

kugRtaMgTajGnuBaØtGacCaplEckrvag yield stress CamYynwgemKuNsuvtßiPaB b¤CaplEckrvag

ultimate tensile stress CamYynwgemKuNsuvtßiPaBepSgeTot. eyIgnwgerobrab;BIGgát;rgkarTajlMGit

enAkñúgEpñk B>2.

eKeRbI ASD sMrab;eRKOgbgÁúMEdkmuneBlEdlmankarENnaMBI LRFD Specification enAkñúgqñaM

1989. kare)aHBum<elIkcugeRkayrbs; ASD Specifcation (AISC, 1989b) ehIynig Manual of

steel Construction (AISC, 1989a) RtUv)anpSBVpSayenAkñúgqñaM 1989. karerobcMÉksarrbs;Éksar

TaMgBIrxagelImanlkçN³RsedogKñanwgkarerobcMÉksarrbs; LRFD Edr. eKEbgEck Specification

CaCMBUk ¬]TahrN_ “Chapter D, Tension members”¦ ehIy Manual RtUv)anEbgEckCaEpñk ¬dUcCa

“Part 2, Beam and Girder Design”¦. enAkñúg Specification mankarENnaM eday Commentary.

*

snμt;faeyIgsÁal; nigyl;BI AISC LRFD Specification nig Manual

473 Appendix B](https://image.slidesharecdn.com/appendixbstructuralsteeldesignbasedonallowablestress-100715205016-phpapp01/75/Appendix-b-structural-steel-design-based-on-allowable-stress-1-2048.jpg)

![T.Chhay

nimitþsBaØaenAkñúgsmIkar B.1 manlkçN³RsedogKñaeTAnwgkareRbIR)as;enAkñúg Specification.

eKeRbIGkSr f sMrab;kugRtaMgEdlKNnaCak;Esþg nigeKeRbIGkSr F sMrab;kugRtaMgGnuBaØat. snÞsSn_

R)ab;BIRbePTkugRtaMg.

edaysar]bsm<½n§enHRKan;EtCaesckþIENnaM dUcenHeyIgminRtUvkareRbIelxEpñkrbs; AISC

Specification b¤elxsmIkareT. smIkarenAkñúg]bsm<½n§enHykecjBI Specification EtelxsmIkar

RtUv)andak;eTAedayxøÜneyIg. elIsBIenH enAeBlEdleyIgeRbIBakü Specification b¤ Manual enA

kñúg]bsm<½n§enH )ann½faeyIgeRbI allowable stress elIkElgEtmankarENnaM.

Ggát;CaeRcInénkarKNnaeRKOgbgÁúMEdkKWRsedogKñasMrab; ASD nig LRFD. ]TahrN_ net

area sMrab;Ggát;rgkarTajKWdUcKña rYmbBa©ÚlTaMg s 2 / 4 g sMrab; staggered holed ¬kartMerobrn§qøas;¦

nigemKuN U sMrab; shear leg ¬eTaHbICa ASD Specification eRbItMélmFümrbs; U nigdak;smIkar

sMrab; U enAkñúg Commentary k¾eday k¾eKeRbIGVIEdlmanenAkñúg LRFD Specification Edr¦.

niymn½yrbs; compact member, noncompact member neg slender member KWdUcKña b:uEnþ LRFD

Specication cugeRkaymankarEklMGeRcIn. CaTUeTA enAeBlmanPaBminRtUvKñarvag ASD nig LRFD

provision eKKYredaHRsayedayQrelI LRFD Specification eRBaHvaTan;sm½ykal.

eTaHCavaminmanemKuNbnÞúkenAkñúg allowable stress design k¾eday eKenAEtGacKit

bnÞúksMxanepSg²enAkñúgkarbnSMbnÞúkEdr. ]TahrN_ CaTUeTAeKeRbIbnSMbnÞúksMrab;eRKOgbgÁúMdMbUldUc

teTA³ D + S / D + W / D + (S / 2) + W nig D + S + (W / 3) . elIsBIenH Specification GnuBaØat

eGay allowable stress ekIneLIgmYyPaKbIenAeBleKrab;bBa©ÚlbnÞúkxül; nigbnÞúkrBa¢ÜydI. Building

code CaeRcInk¾mankarpþl;EbbenHEdr.

ASD Manual k¾mantarag nigdüaRkamCaeRcInRsedogKñanwg LRFD Manual Edr. eyIgnwg

elIkykEttarag b¤düaRkamNaEdlsMxan;mkbkRsayenAkñúgkarENnaMd¾segçbenH.

B >2> Ggát;rgkarTaj Tension members

BIsmIkar B.1 kugRtaMgTajtamG½kSEdlKNnaKW ft = P / A . Allowable stress KWQrelI

sßanPaBkMNt; yielding nig fracture EdleRKaHfñak;CageK. sMrab; yielding rbs; gross section kug

RtaMgGnuvtþn_KW

474 Appendix B](https://image.slidesharecdn.com/appendixbstructuralsteeldesignbasedonallowablestress-100715205016-phpapp01/85/Appendix-b-structural-steel-design-based-on-allowable-stress-2-320.jpg)

![NPIC

P

ft = (B.2)

Ag

Edl Ag Ca gross cross-sectional area. The factor of safety sMrab;sßanPaBkMNt;enHKW 5 / 3

ehIykugRtaMgGnuBaØatKW

Fy Fy

Ft = = = 0.6 Fy (B.3)

F .S . 5/3

sMrab; fracture rbs; net section

P

ft = (B.4)

Ae

Edl Ae Ca effective net area. emKuNsuvtßiPaBKW 2.0 EdllT§plrbs;kugRtaMgGnuBaØatKW

Fu F

Ft = = u = 0.5 Fu (B.5)

F .S 2

]TahrN_ B>1³ RtYtBinitükugRtaMgenAkñúgGgát;rgkarTajEdlbgðajenAkñúgrUbTI B>1 EdlekItBIbnÞúk

eFIVkar 50kips . eKeRbIEdkRbePT A36 nigb‘ULúgGgát;p©it 7 8 in. .

dMeNaHRsay³ BIsmIkar B.2 nig B.3 kugRtaMgGnuvtþn_enAelI gross section KW

P 50

ft = = = 20.2ksi

Ag 2.48

ehIykugRtaMgGnuBaØatKW

Ft = 0.5Fy = 0.60(36) = 21.6ksi > 20.2ksi (OK)

kugRtaMgenAelI net area KW

An = Ag − (thickness × hole diameter )

3⎛ 7 1⎞

= 2.48 − ⎜ + ⎟ = 2.105in.2

8⎝ 8 8⎠

RbsinebIeyIgeRbItMélmFüm U enaH effective net area KW

475 Appendix B](https://image.slidesharecdn.com/appendixbstructuralsteeldesignbasedonallowablestress-100715205016-phpapp01/85/Appendix-b-structural-steel-design-based-on-allowable-stress-3-320.jpg)

![T.Chhay

]TahrN_ B>2³ kMNt;bnÞúkeFVIkarGnuBaØat P sMrab;Ggát;rgkarsgát;EdlbgðajenAkñúgrUbTI B>3.

dMeNaHRsay³ RtYtBinitüemIlfaetIGgát;CaGgát;Edlmanmuxkat; slenderb¤Gt;. pleFobTTwgelI

kMras;sMrab;Ggát;rgkarsgát;EdleGayenAkñúg ASD Specification manlkçN³dUcKñaenAkñúg LRFD

Specification:

bf

2t f

= 6 .4 ¬BI properties table EdlmanenAkñúg Manual¦

95 95

= = 15.8 > 6.4 (OK)

Fy 36

h

= 25.3

tw

253 253

= = 42.2 > 25.3 (OK)

Fy 36

kugRtaMgKW f a = P / Ag dUcenHbnÞúkEdlRtUvKñaKW P = f a Ag ehIybnÞúksgát;GnuBaØtKW Fa Ag . BI

smIkar B.8

2π 2 E 2π 2 (29000)

Cc = = = 126.1

Fy 36

pleFob slenderness GtibrmaKW

KL KL KL 1.0(20)(12)

= = = = 96.77

r rmin ry 2.48

lT§plEdlTTYl)antUcCag Cc dUcenHeKGacrk Fa BIsmIkar B.9:

478 Appendix B](https://image.slidesharecdn.com/appendixbstructuralsteeldesignbasedonallowablestress-100715205016-phpapp01/85/Appendix-b-structural-steel-design-based-on-allowable-stress-6-320.jpg)

![T.Chhay

yktMélFMCageKkñúgcMeNam

170000Cb

Fb = ≤ 0.60 Fy (US) (elastic nonuniform warping) (B.20)

(Lb / rT )2

1172150Cb

Fb = ≤ 0.60 Fy (IS)

(Lb / rT )2

nig Fb =

12000Cb

Lb d / A f

≤ 0.60 Fy (US) (uniform warping) (B.19)

82750Cb

Fb = ≤ 0.60 Fy (IS)

Lb d / A f

ASD Specification eGaynUvsmIkarsMrab; Cb EdlxusBI Cb EdleGayeday LRFD

Specification b:uEnþeKGaceRbImYyNak¾)an. cMNaMfa eTaHbICa flexural strength Edleyagtam

LRFD KWsmamaRtedaypÞal;eTAnwg Cb k¾eday k¾vaminEmnCakrNIsMrab; allowable stress Edl

eGayedaysmIkar B.18 - B.20 Edr. vamankarsμúKsμajxøHkñúgkarKNna allowable stress rbs;Fñwm.

Shear

kugRtaMgkMlaMgRtUv)anKNnaedayykbnÞúkkMlaMgkat;eFVIkarGtibrmaEcknwgRkLaépÞRTnug.

V V

fv = ≈

Aw t w d

kugRtaMgkMlaMgkat;KWQrelI shear yielding ehIyRtUv)anykesμInwgBIrPaKbIénkugRtaMgTaj

GnuBaØatelI gross section.

Fv =

2

3

2

( )

Ft = 0.60 Fy = 0.40 Fy

3

(B.21)

]TahrN_ B>3³ eKeRbI sMrab;FñwmTMrsamBaØEdlrgbnÞúkBRgayesμIehIyman lateral

W 16 × 100

bracing EtenAxagcugrbs;va. RbsinebIeKeRbIEdkRbePT A36 kMNt;m:Um:g;Bt;eFVIkarGtibrmaEdlFñwm

enHGacTb;)ansMrab;ElVgEdlmanRbEvg (a) 10 ft (b) 15 ft nig (c) 40 ft .

dMeNaHRsay³ dMbUg kMNt; Lc

BIsmIkar B.12

76b f 76(10.42 )

= = 132in = 11 ft

Fy 36

484 Appendix B](https://image.slidesharecdn.com/appendixbstructuralsteeldesignbasedonallowablestress-100715205016-phpapp01/85/Appendix-b-structural-steel-design-based-on-allowable-stress-12-320.jpg)

![T.Chhay

f a f bx f by

+ + ≤ 1 .0 (B.24)

Fa Fbx Fby

RbsinebI f a / Fa > 0.15 / eKRtUvRtYtBinitüsmIkarTaMgBIrxageRkam³

fa C mx f bx C my f by

+ + ≤ 1 .0 (B.25)

Fa ⎛ fa ⎞ ⎛ fa ⎞

⎜1 −

⎜ F ' ⎟ Fbx ⎜1 −

⎟ ⎟F

⎝ ex ⎠ ⎜ F 'ey ⎟ by

⎝ ⎠

f by

nig fa f

+ bx +

0.6 Fa Fbx Fby

≤ 1 .0 (B.26)

smIkar B.25 CakarRtYtBinitüesßrPaB ehIyeKeRbIm:Um:g;Bt;GtibrmaedIm,IKNna f bx nig f by .

smIkar B.26 EdlmineRbI amplification factor CakarRtYtBinitükugRtaMg ehIyeKeRbIm:Um:g;cugGtibrma

edIm,IKNna f bx nig f by . cMNaMfa eKeRbI 0.60Fy CMnYseGay Fa enAkñúgsmIkar B.26 edaysar

sßanPaBkMNt;Ca yielding CaCag buckling. sMrab;mUlehtudUcKña eKGacBicarNaGgát;Ca laterally

supported member sMrab;karKNna Fbx enAkñúgsmIkar B.26 b:uEnþeKRtUvKitlkçxNÐ lateral bracing

Cak;EsþgenAeyIgeRbIsmIkar B.25 edIm,IRtYtBinitü.

eKalbMNgrbs;emKuN Cmx enAkñúgsmIkar B.25 KWedIm,IKitBI gradient m:Um:g;eFobG½kS x

rbs;Ggát;. enAkñúg laterally supported member eKeRbIemKuN Cb kñúgkarKNna Fbx k¾edIm,IKitBI

gradient Edr. dUcenH Specification yk Cb esμImYyenAeBlEdleKKit Fbx sMrab;eRbIenAkñúgsmIkar

B.25 sMrab;Ggát;EdlBRgwgRbqaMgnwgkarrMkiltMN (members braced againt joint translation).

]TahrN_ B>4³ Beam-column EdlbgðajenAkñúgrUbTI B.7 CaEpñkrbs; braced frame. karBt;KWeFob

nwgG½kS x ehIycugrbs;vaRtUvman lateral bracing . snμt;fa K x = K y = 1.0 cUrviPaKGgát;eday

eKarBtam AISC Specification.

488 Appendix B](https://image.slidesharecdn.com/appendixbstructuralsteeldesignbasedonallowablestress-100715205016-phpapp01/85/Appendix-b-structural-steel-design-based-on-allowable-stress-16-320.jpg)

![NPIC

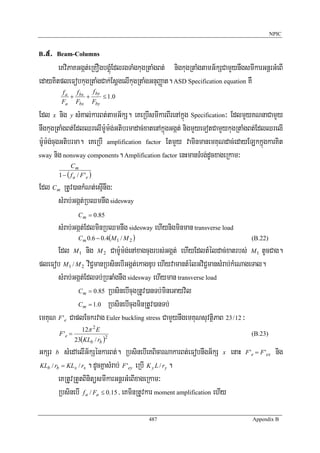

12π 2 E 12π 2 (29000)

ehIy F 'ex = = = 87.21ksi

23(K x L / rx )2 23(41.38)2

fa C mx f bx 0.8333(13.19)

+ = 0.4250 + = 0.978 < 1.0 (OK)

Fa ⎛ fa ⎞ ⎛ 6.944 ⎞

⎜1 −

⎜ F ' ⎟ Fbx ⎟ ⎜1 − ⎟21.6

⎝ ex ⎠ ⎝ 87.21 ⎠

cemøIy³ W 10 × 49 RKb;RKan;

Design Aids

eRkABItarag nigdüaRkamsMrab;KNnassr nigFñwm principal Manual design aid sMrab; beam-

column CataragéntMélefrsMrab;eRbIkñúgkareRCIserIsmuxkat;dMbUg (Burgett, 1973). tMélefrTaMgenH

GaceGayGñkKNnabMElgm:Um:g;Bt;eGayeTACabnÞúktamG½kSsmmUlEdlGacpSMCamYynwgbnÞúkCak;

EsþgedIm,ITTYl)anbnÞúktamG½kSRbsiT§PaBsrub. bnÞab;mkeKGacbBa©ÚlbnÞúktamG½kSRbsiT§PaBenH

eTAkñúg Column allowable load table eKnwgTTYl)anmuxkat;sakl,gEdleKGacykvaeTAsikSa

epÞógpÞat;)an.

B >6> snñidæan Concluding Remarks

eTaHbICa ASD RtUv)anCMnYsy:agelOneday LRFD k¾eday k¾vaenAEtRtUv)anGnuBaØateGay

eRbIeday AISC dEdl ehIyeBlxøHk¾eKenAEteRbIvaEdr. sMrab;GñksikSaEdlmanbMNgcg;dwglMGitBI

ASD elIsBIGVIEdl)anerobrab;kñúg]bsm<½n§enHGacrk)anenAkñúg Design of Steel structure (Gaylord

and stallmeyer, 1992) EdlenAkñúgenaHk¾manerobrab;BI AISC Specification provision pgEdr.

491 Appendix B](https://image.slidesharecdn.com/appendixbstructuralsteeldesignbasedonallowablestress-100715205016-phpapp01/85/Appendix-b-structural-steel-design-based-on-allowable-stress-19-320.jpg)