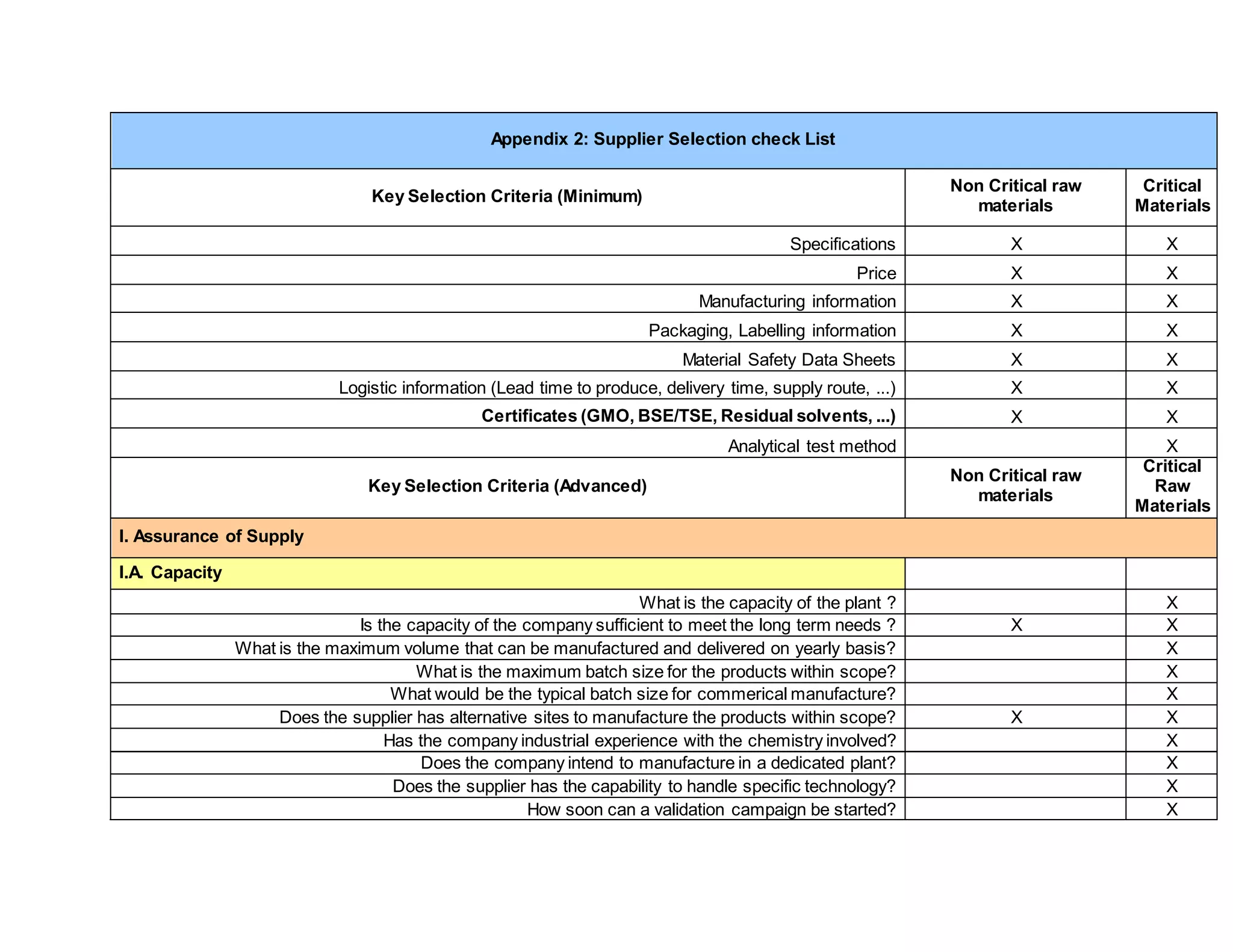

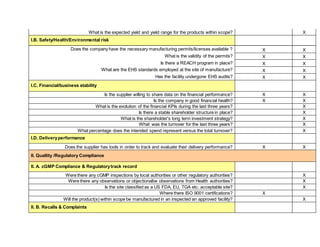

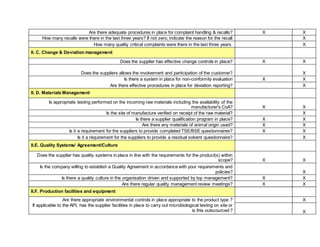

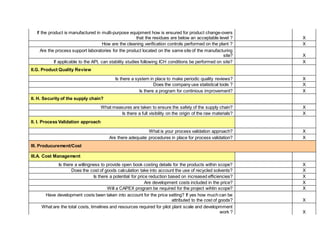

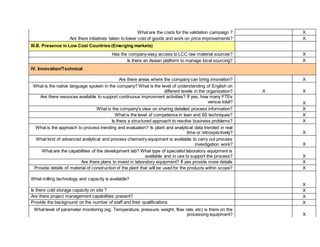

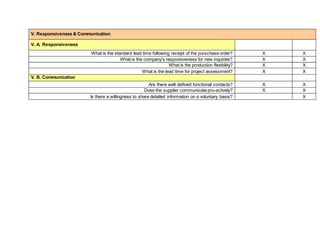

This document provides a supplier selection checklist covering key criteria for selecting suppliers of non-critical and critical raw materials. The checklist includes minimum criteria like specifications, price, and documentation as well as more advanced criteria assessing assurance of supply, quality/regulatory compliance, procurement/cost, innovation/technical capabilities, and responsiveness/communication. Selection depends on suppliers' ability to meet specifications, ensure stable supply at a competitive price, maintain high quality standards, and demonstrate technical and organizational strengths.