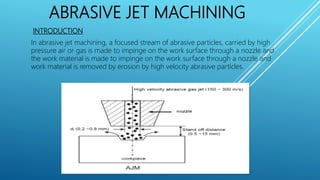

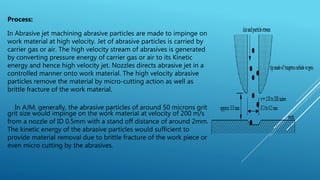

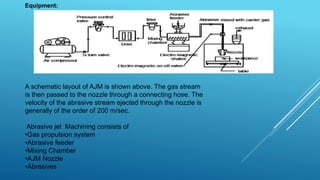

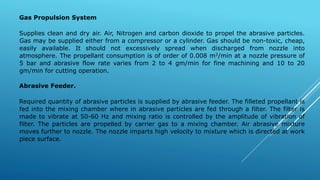

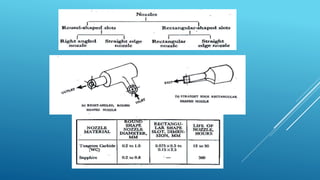

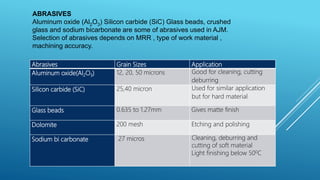

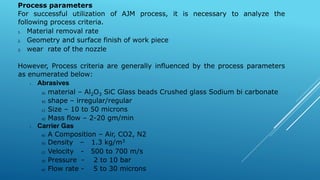

Abrasive jet machining is a non-traditional machining process that removes material by directing a high-velocity stream of abrasive particles carried by a gas through a nozzle onto a workpiece. The abrasive particles impact the workpiece surface at speeds up to 300 m/s, removing material through micro-cutting and brittle fracture. Key aspects of the process include the abrasive particles (usually aluminum oxide or silicon carbide around 50 microns in size), gas propulsion system, abrasive feeder, mixing chamber and nozzle (made of tungsten carbide). Abrasive jet machining can efficiently machine intricate shapes in hard, brittle materials like ceramics and glass with low heat impact.