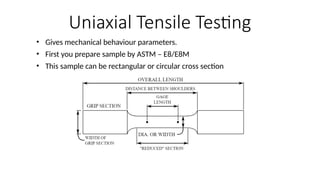

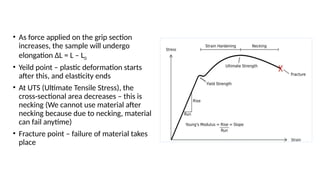

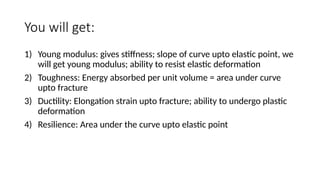

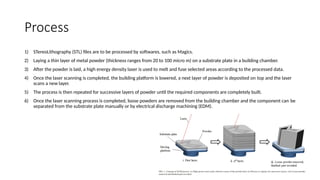

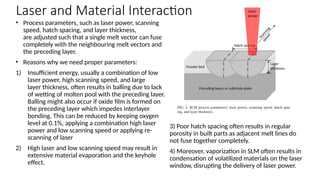

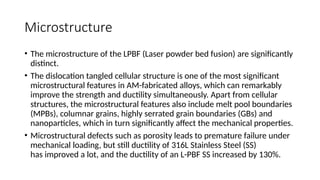

The document discusses uniaxial tensile testing, detailing the preparation of samples and the parameters obtained from testing, such as Young's modulus, toughness, ductility, and resilience. It highlights the importance of cutting techniques for tensile samples using low-speed cutting machines to minimize material waste and the subsequent creation of conducting molds for microstructural analysis. Additionally, it covers various additive manufacturing (AM) technologies, with a focus on selective laser melting (SLM), and the effects of thermal fluctuations and microstructure on the mechanical properties of materials.