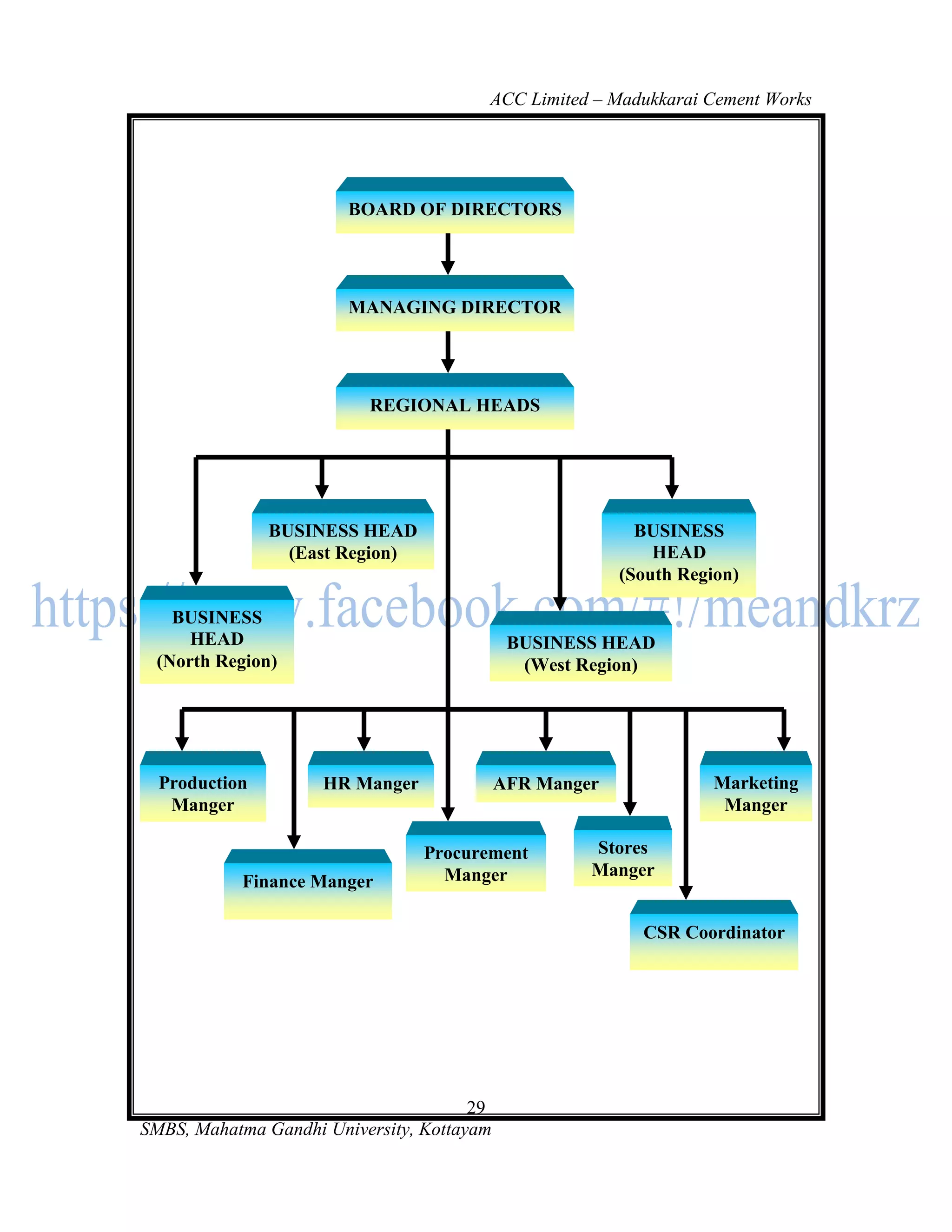

The document provides an overview of the cement industry in India. It discusses the history and invention of cement. The cement industry in India is the 2nd largest producer of cement globally. There are over 140 large cement plants and 365 mini cement plants. The capacity of the Indian cement industry has grown significantly in recent years through large capacity additions. The industry saw double digit growth in capacity between FY03-07. It is an important industry for the growth and development of infrastructure in India.

![ACC Limited – Madukkarai Cement Works

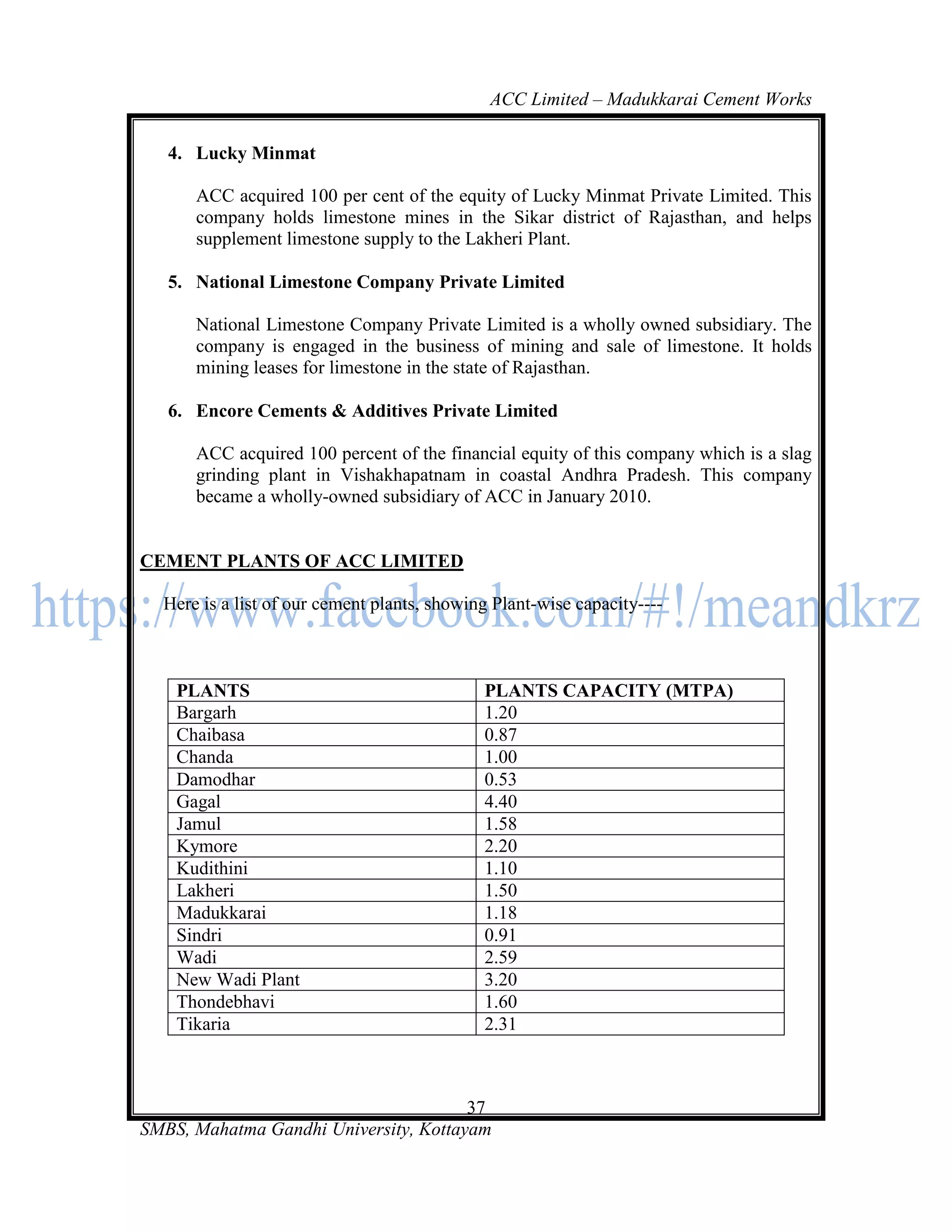

Foreign Promoters Group Disclosure

Foreign Promoters shareholding in the Company is held by Holderind Investments Ltd.

Maruitius and indirectly through its Indian subsidiary Ambuja Cements India Pvt. Ltd.

Holderind Investments Ltd., Mauritius (Holcim Mauritius) has informed the Company

that, Holcim Limited, Holderfin B.V., Holcim(India) Private Ltd. And Ambuja Cements

India Pvt. Ltd. Are companies belonging to the same group (hereinafter referred as

―Holcim Group‖) as defined under the Monopolies and Restrictive Trade Practices Act,

1969.

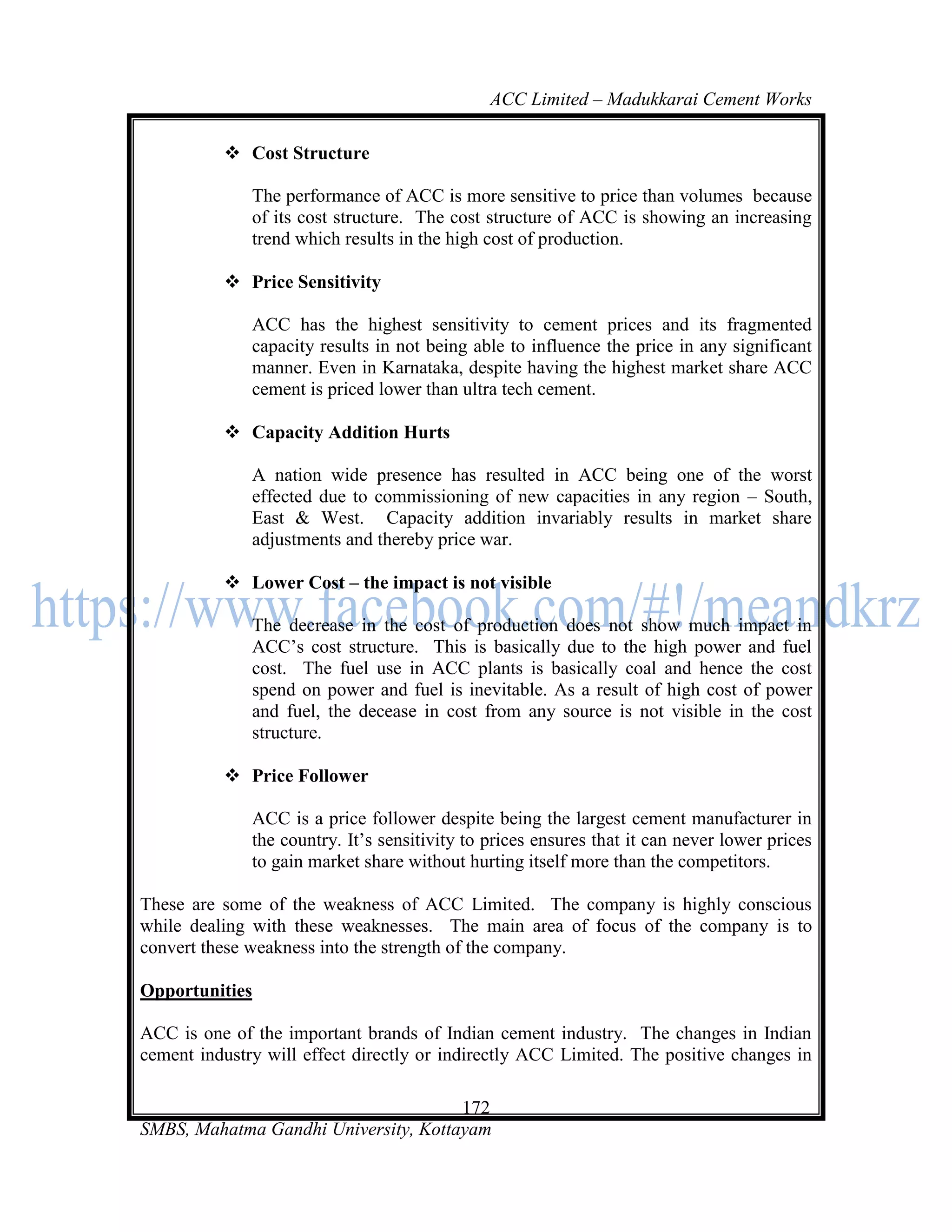

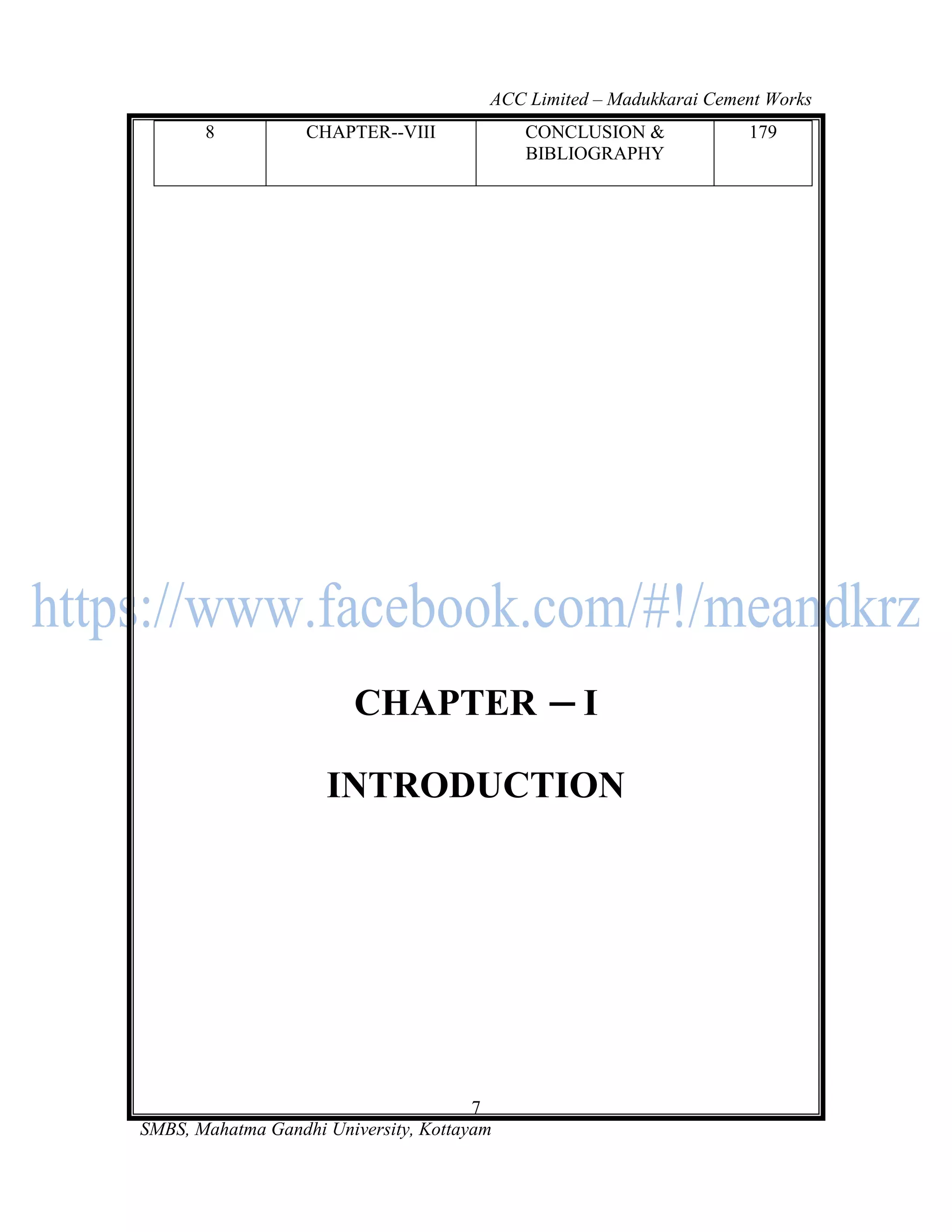

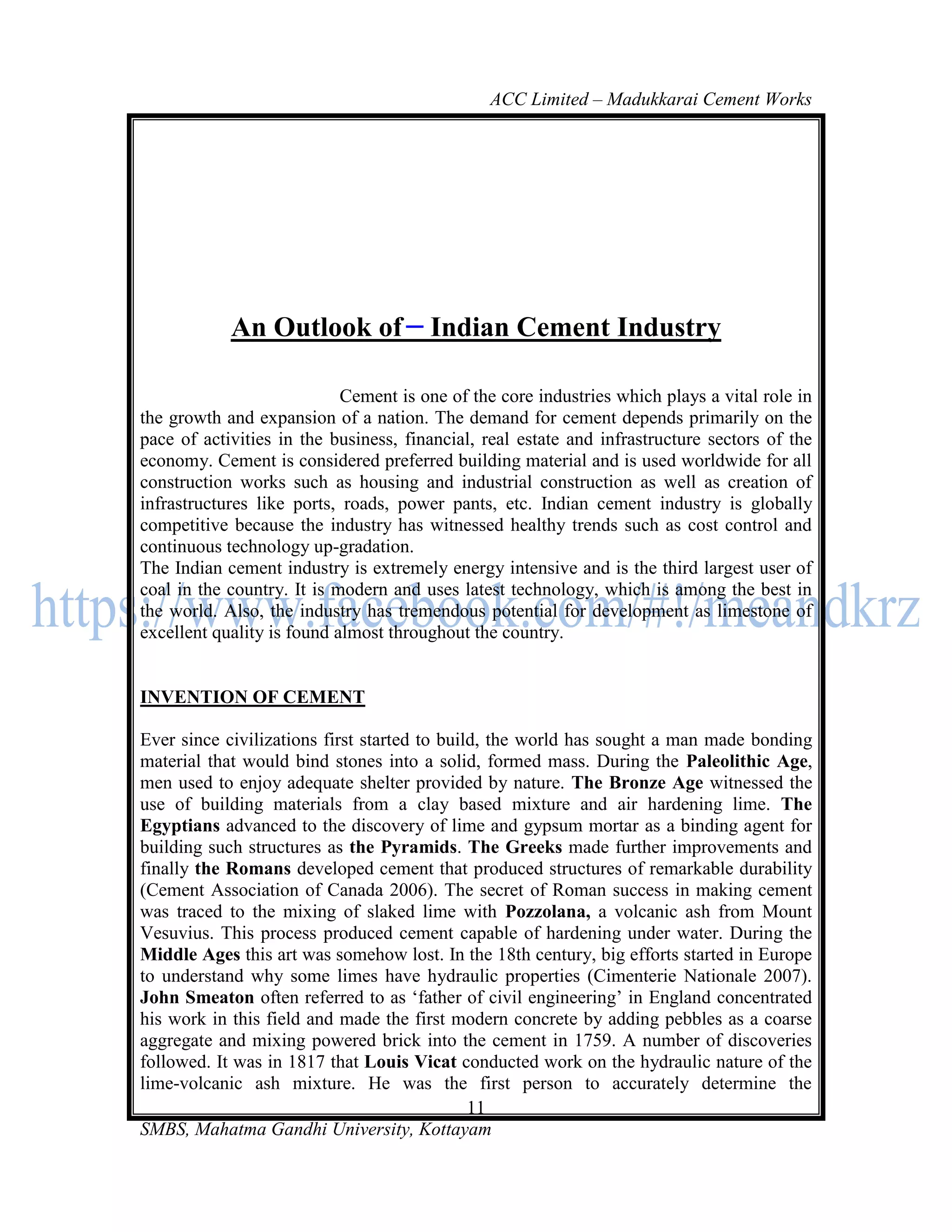

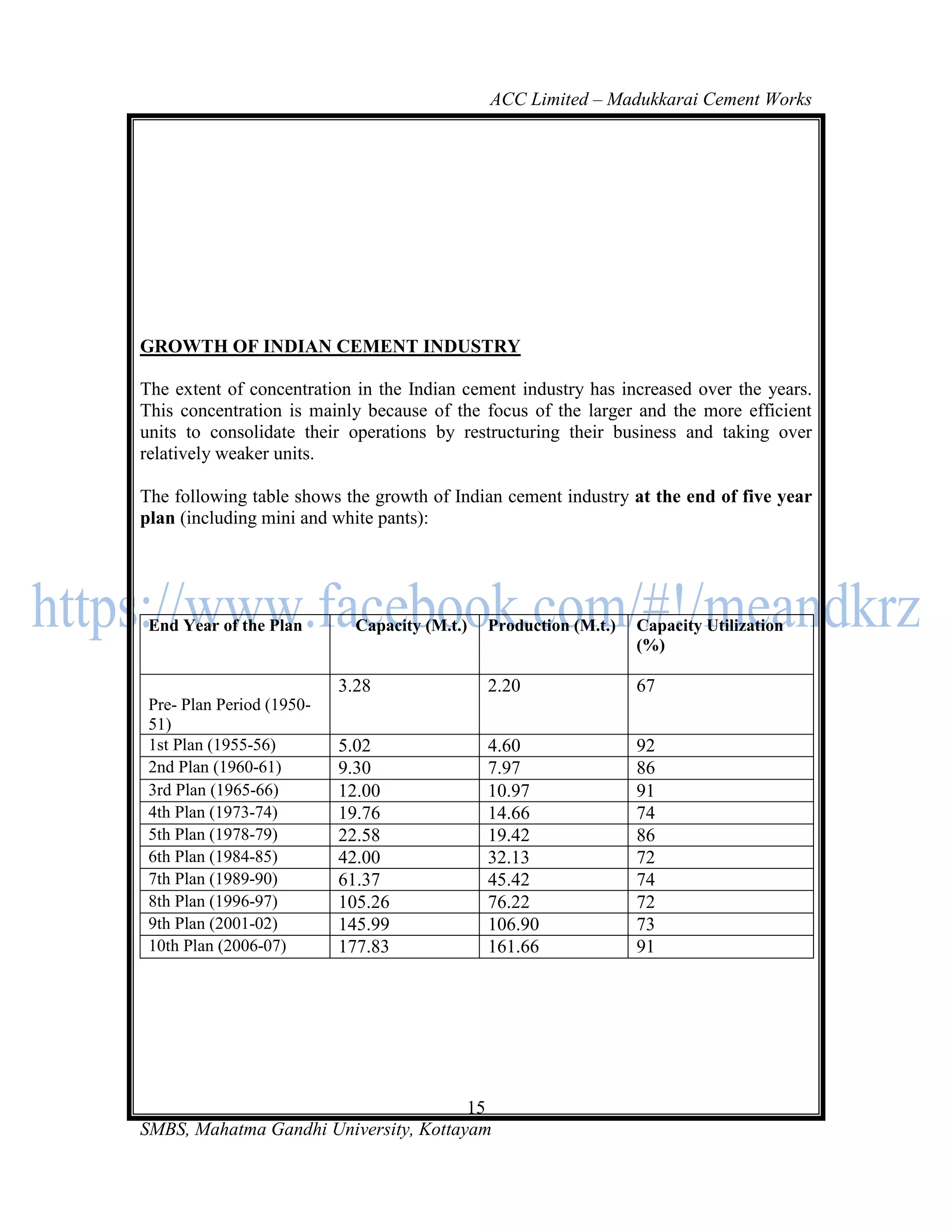

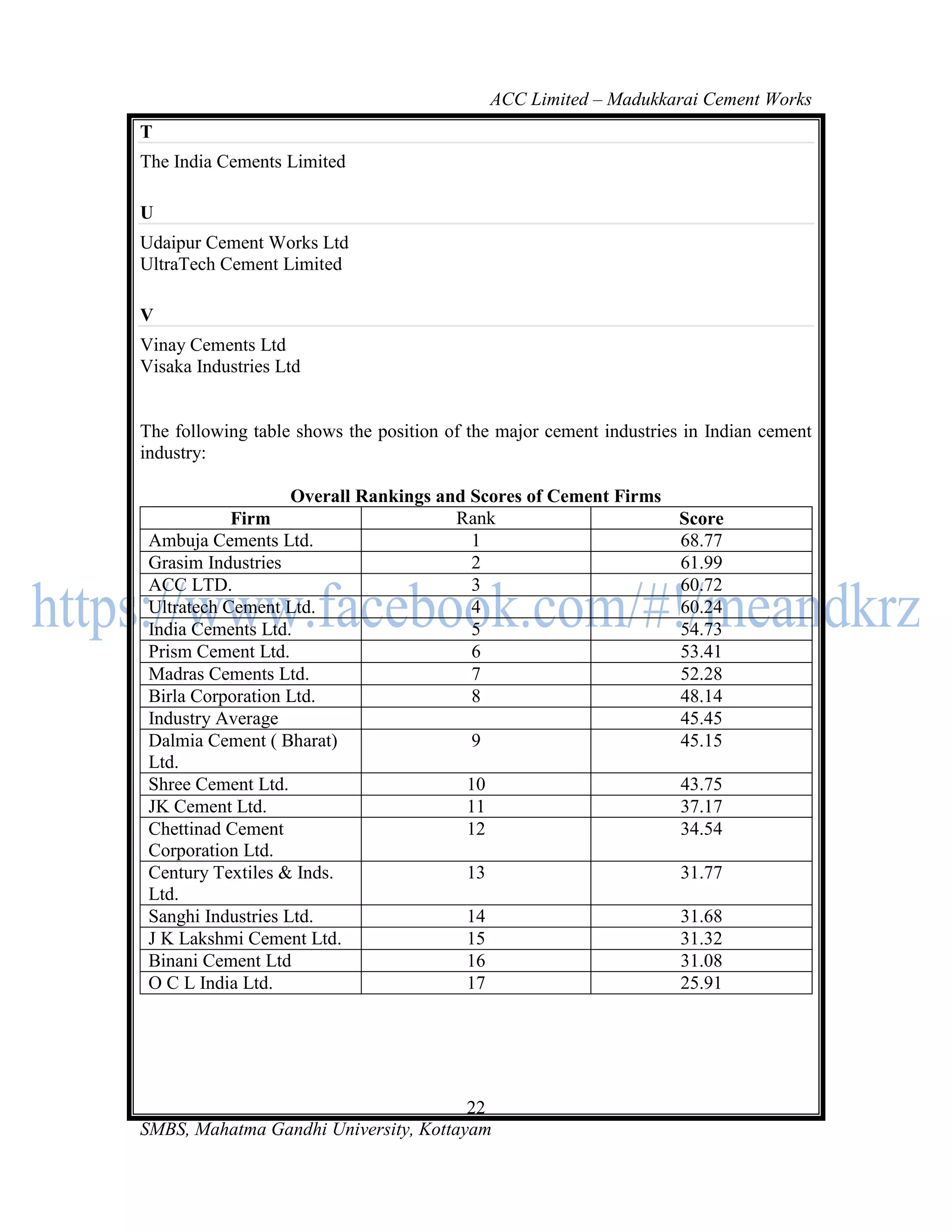

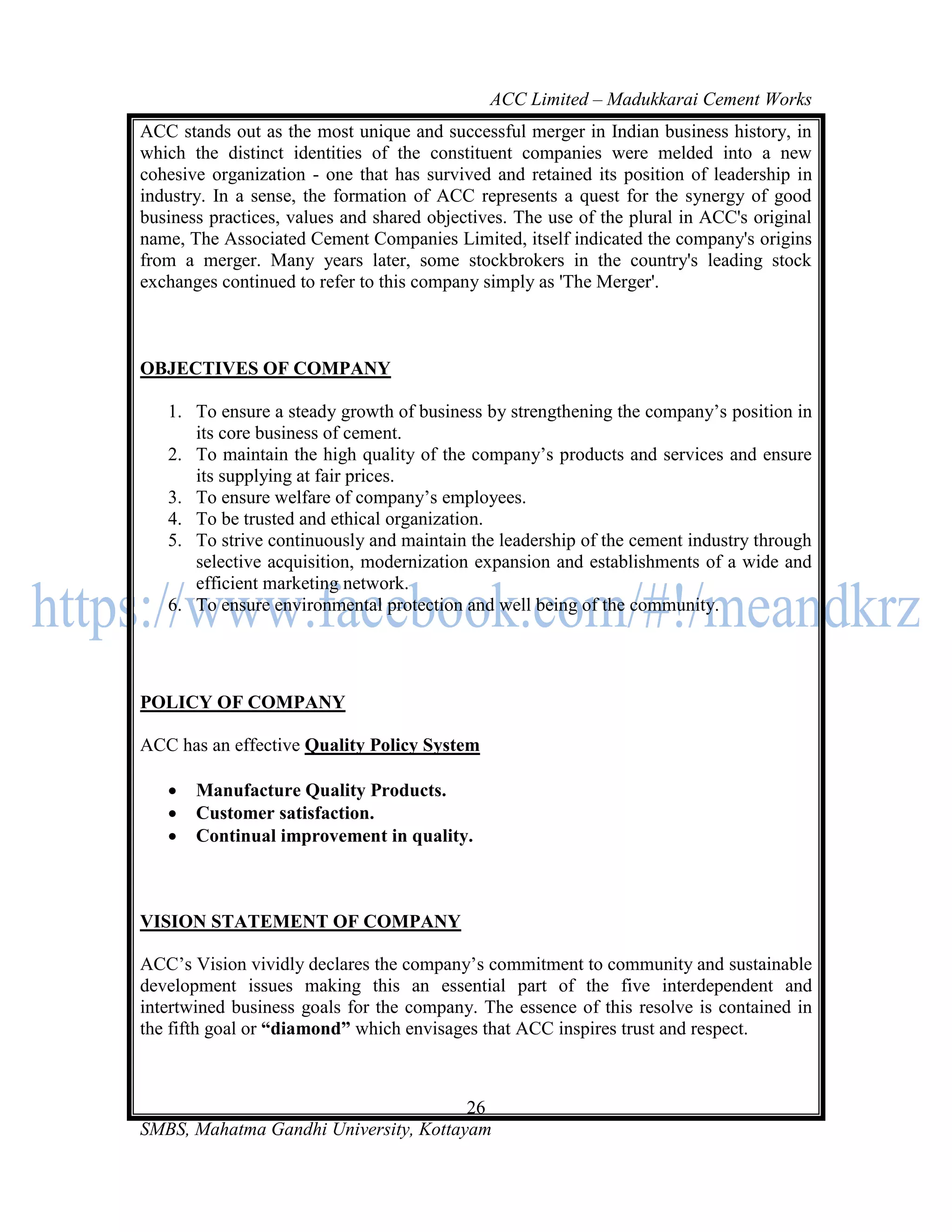

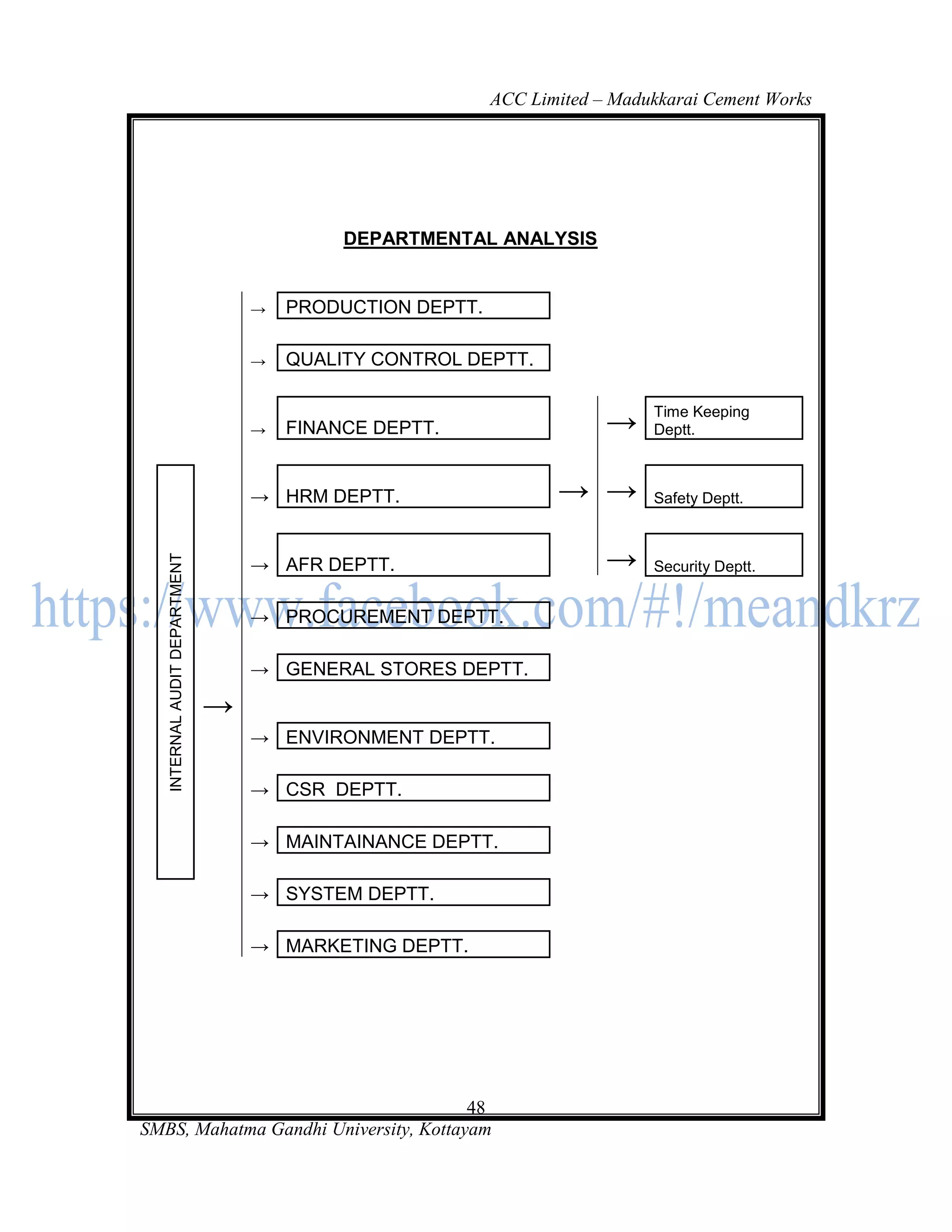

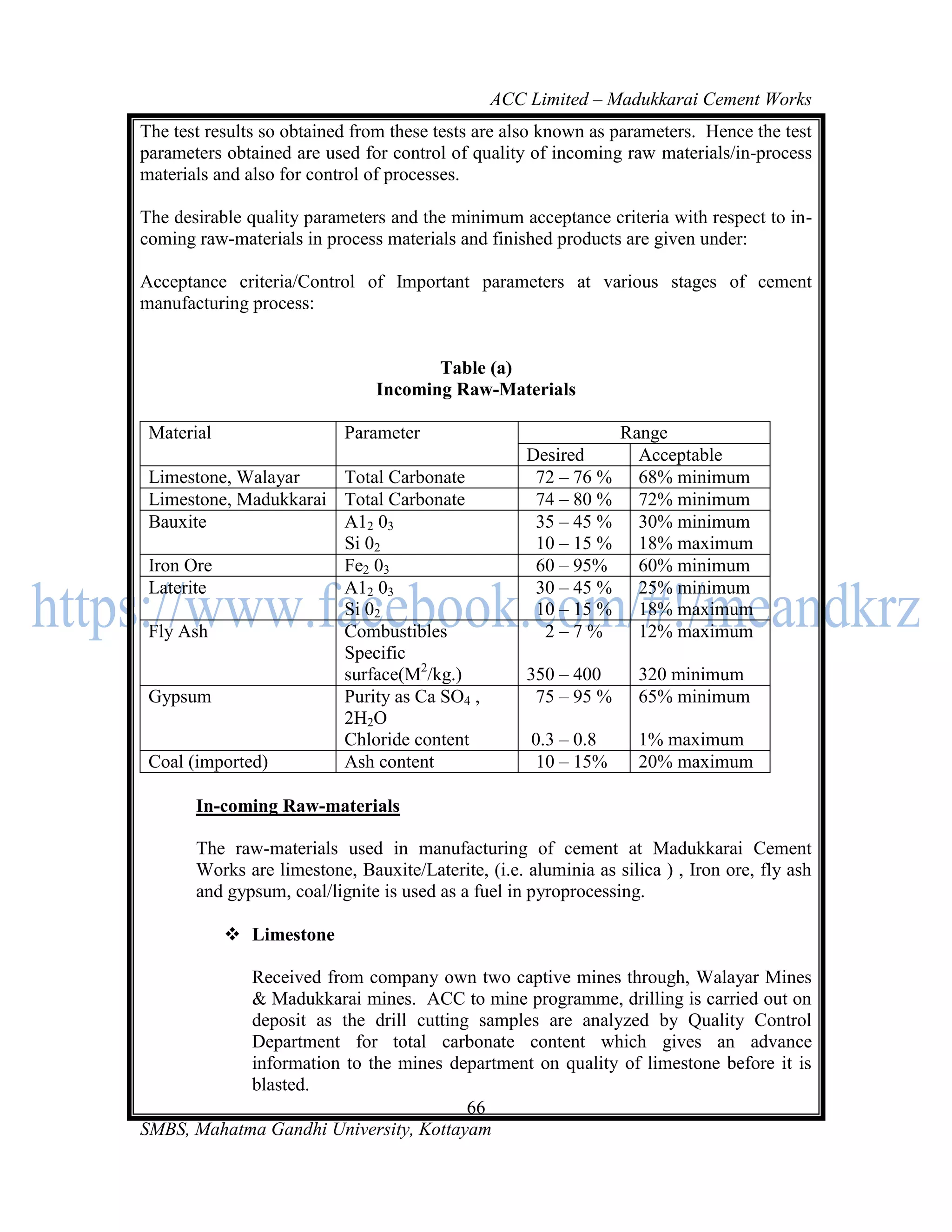

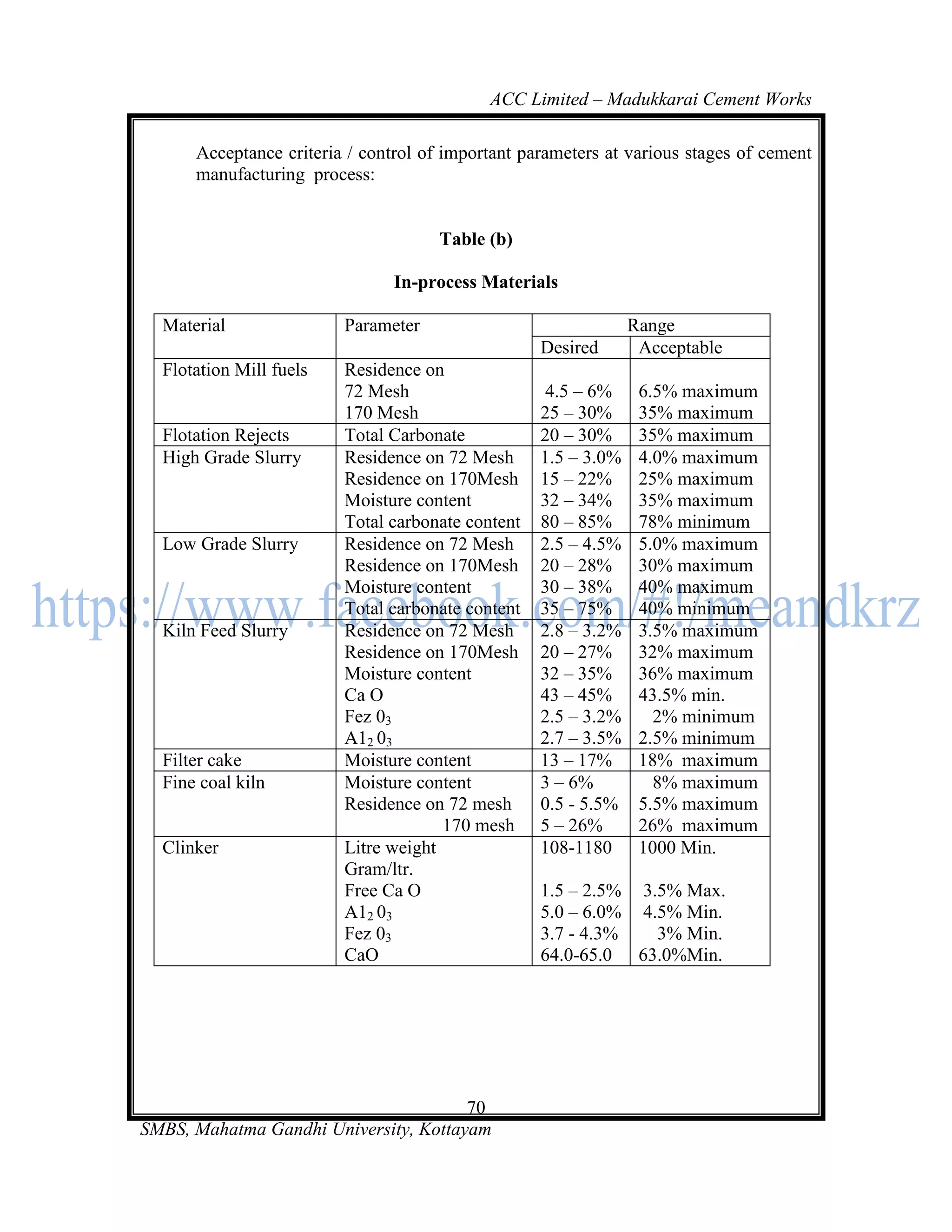

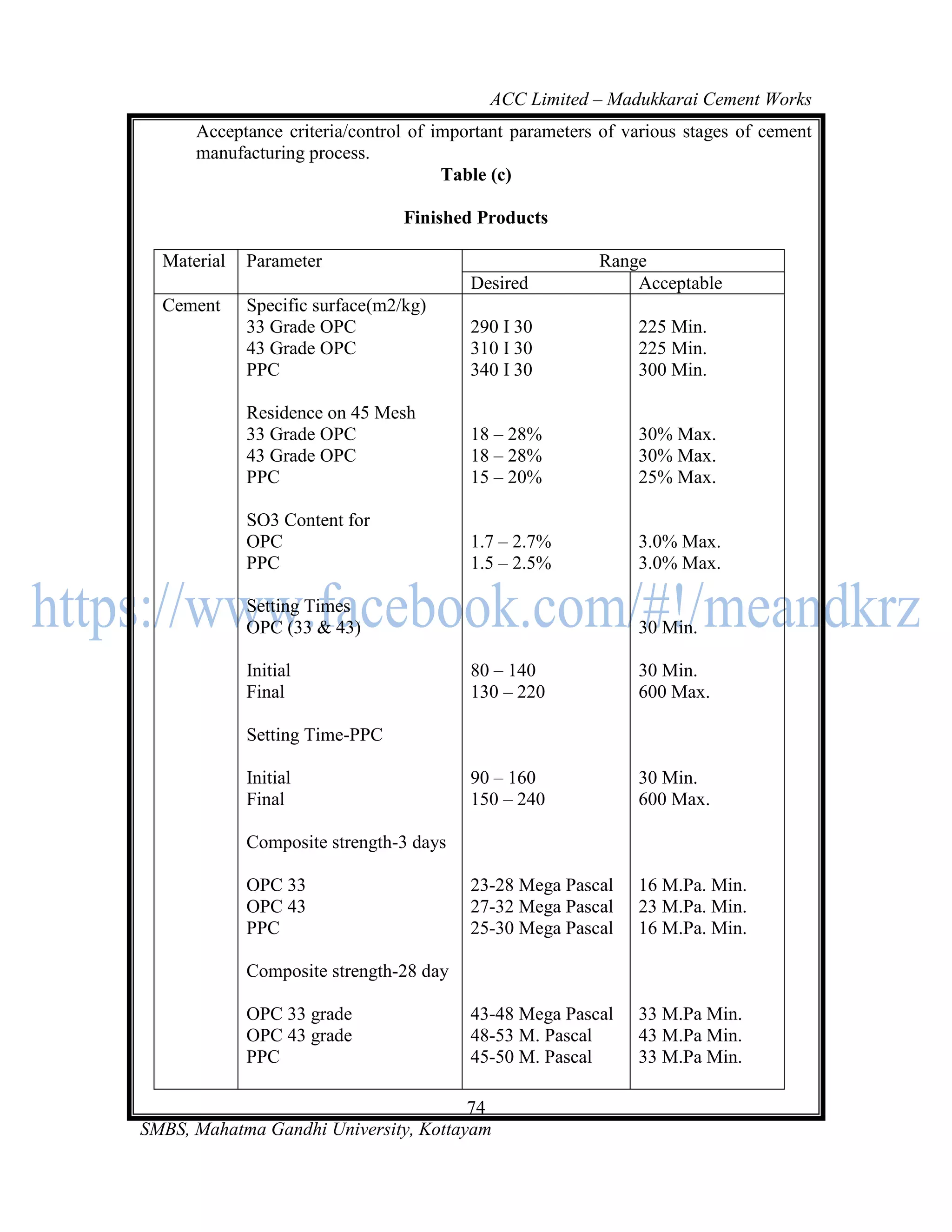

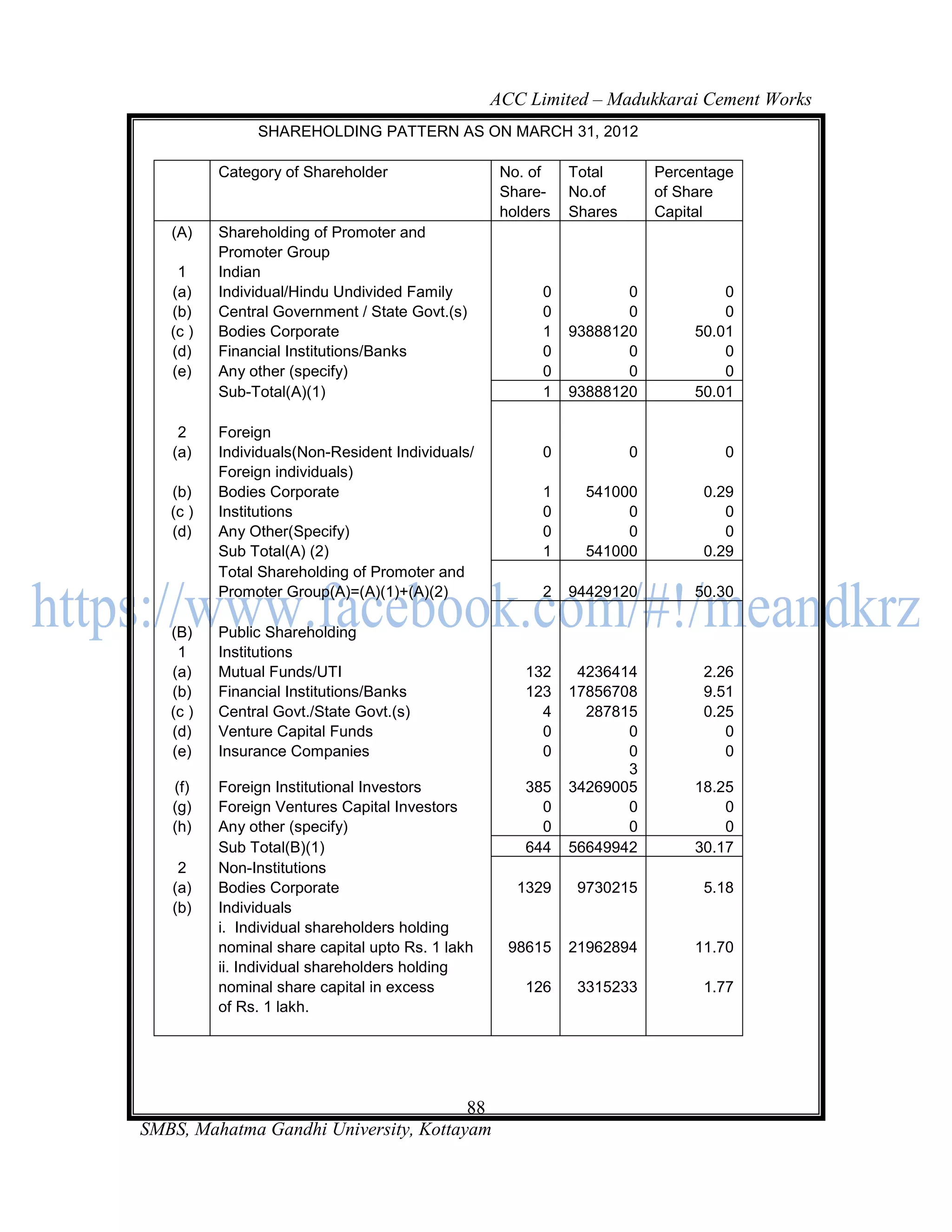

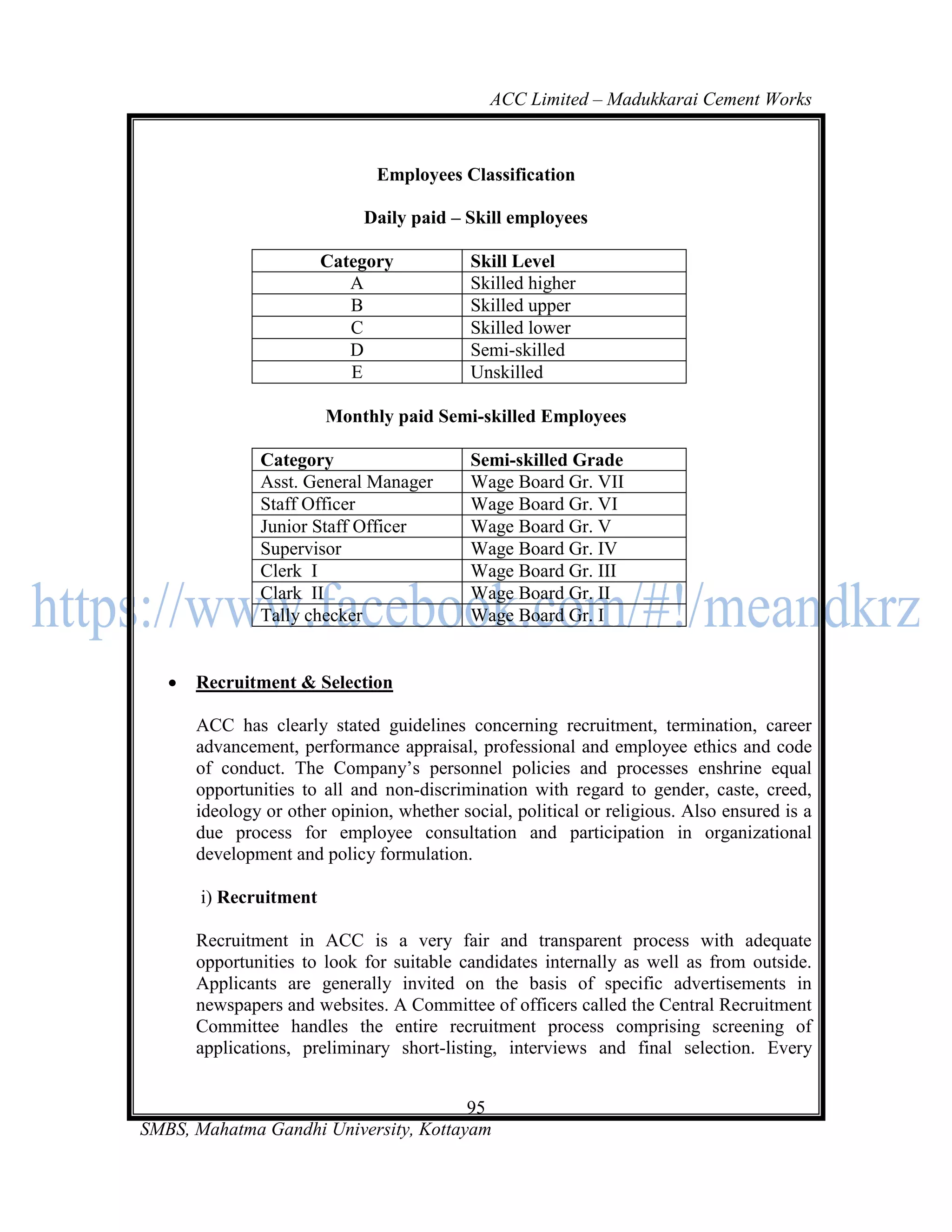

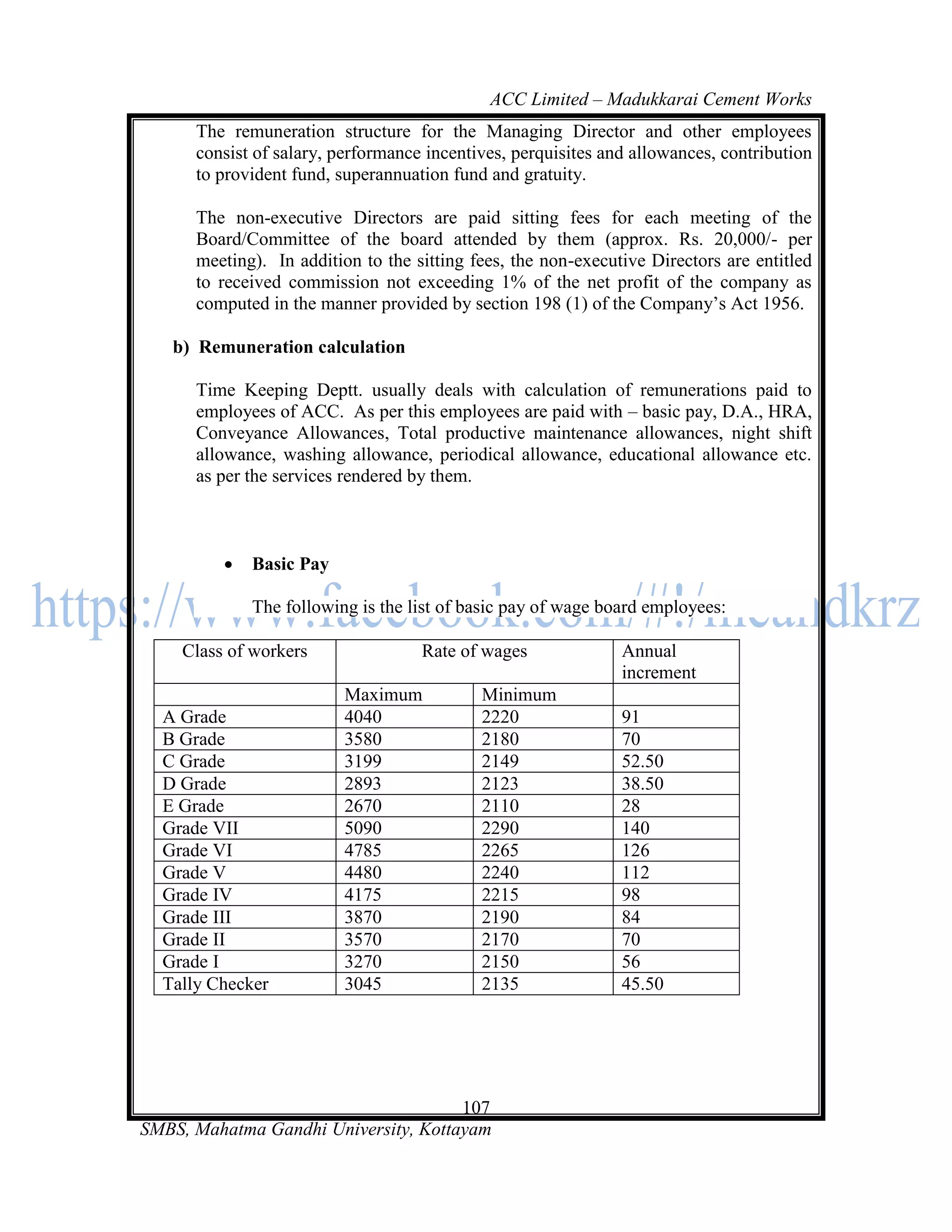

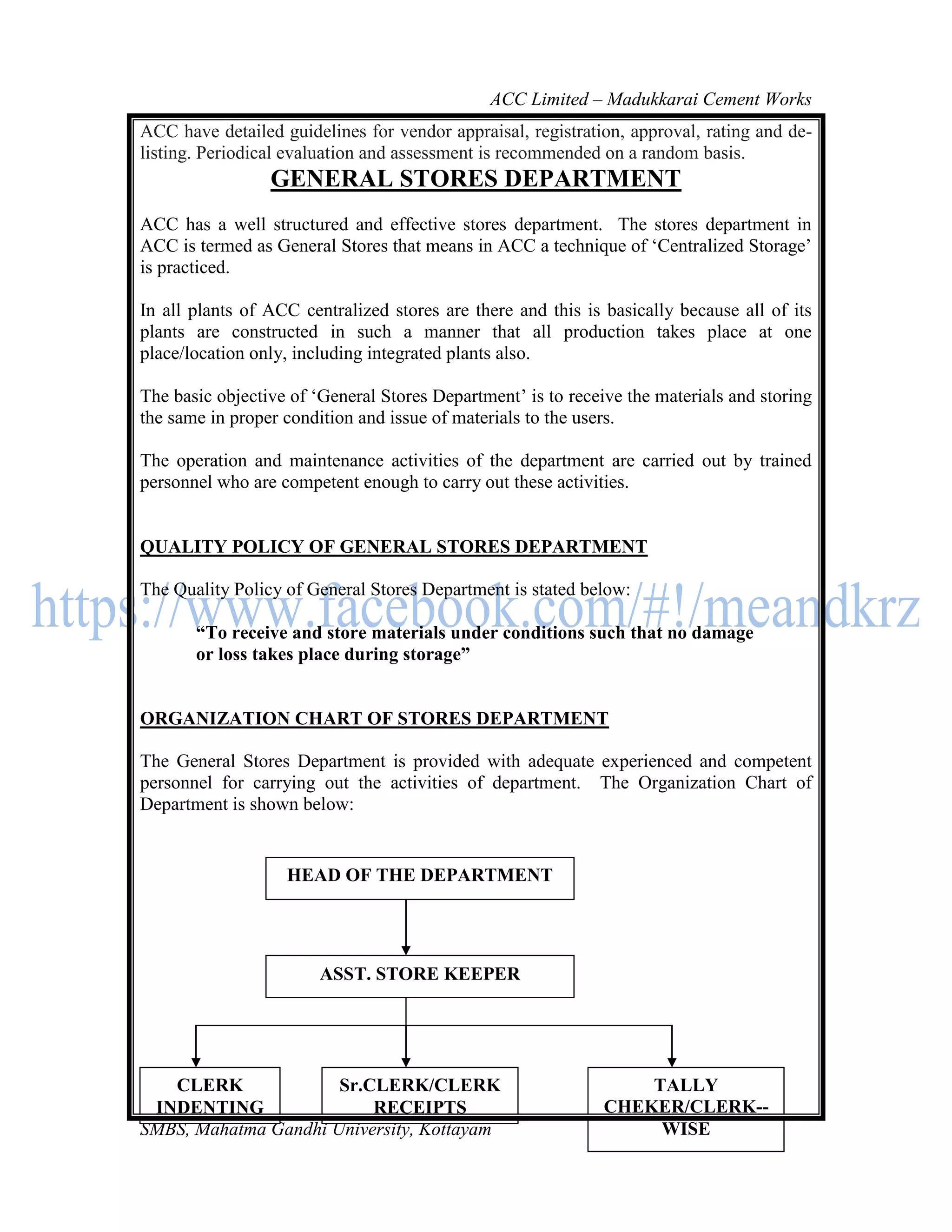

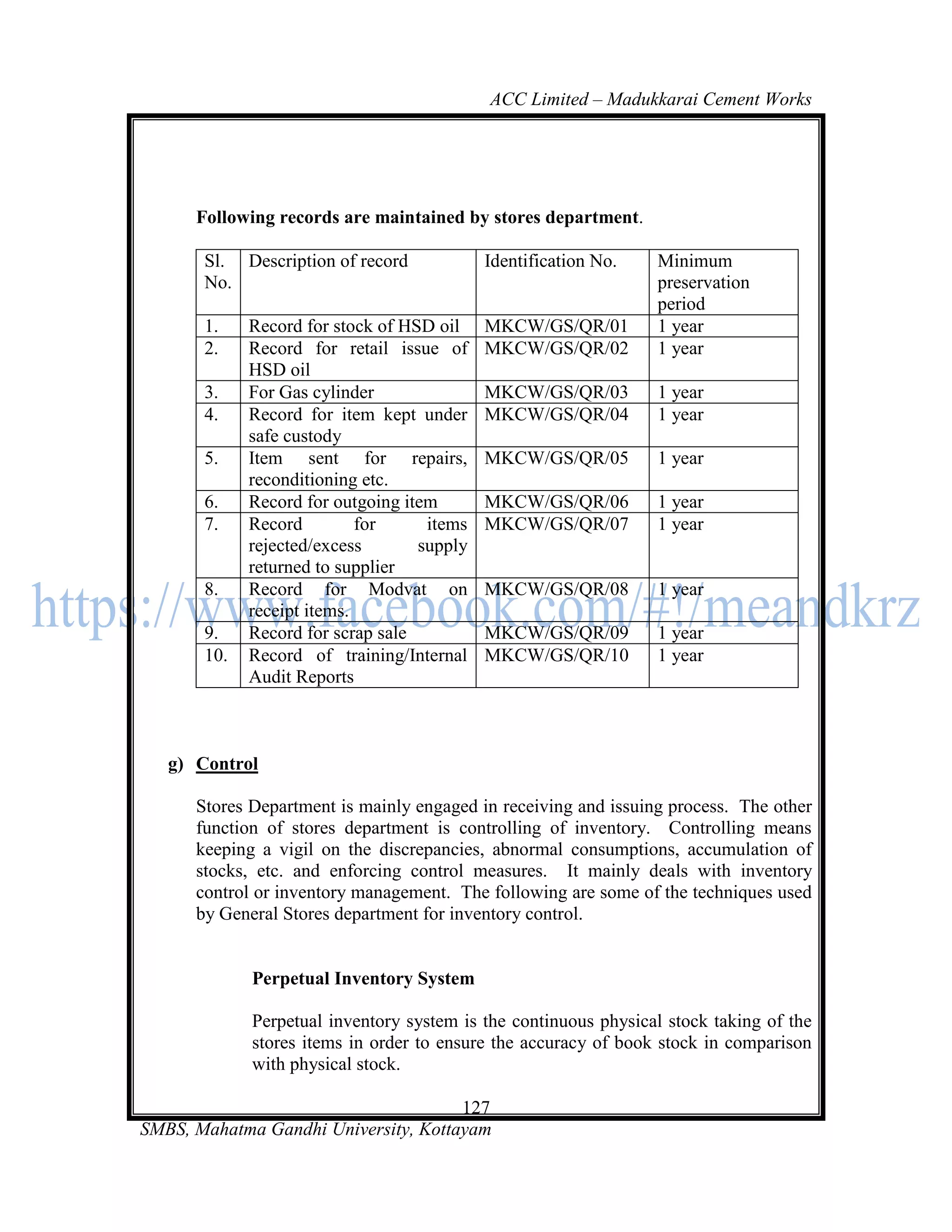

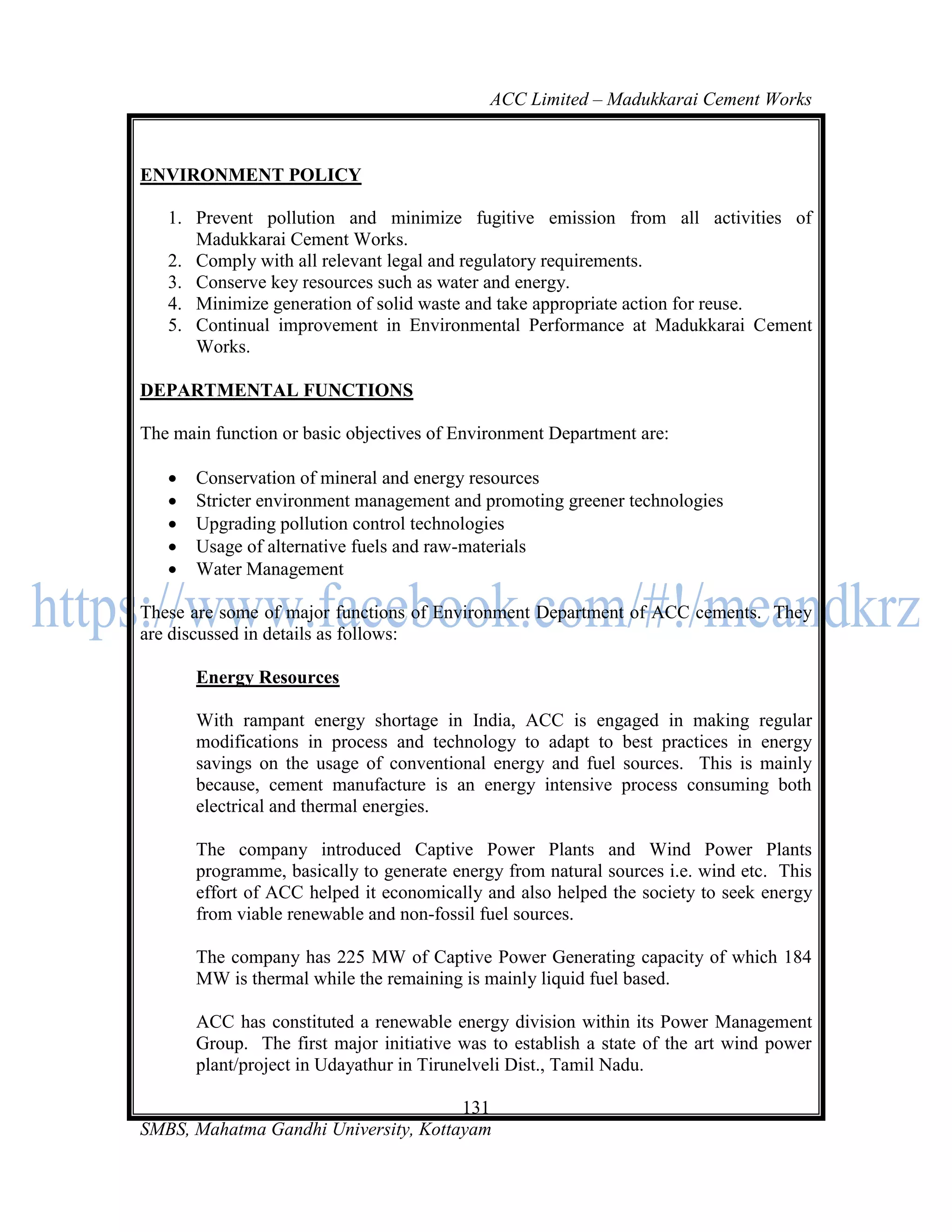

Statement showing Shareholding or more than 1% of the Capital as on 31.12.2009

Category of Shareholder No. of Total Percentage

Share- No.of of Share

holders Shares Capital

1 Ambuja Cement India Pvt.Ltd.(Promoter) 86191067 86732067 46.20

Holderind Investments Ltd.(Promoter) 541000

2 Life Insurance Corporation of India 31681260 16.88

3 ICICI(Prudential Life Insu.Co.Ltd.) 4984776 2.66

4 J.P.Morgan Asset Management(Europe)

S.A.R.L A/c JP Morgan Funds Emerging

Market Equity Fund 3067219 1.63

TOTAL 126465322 67.36

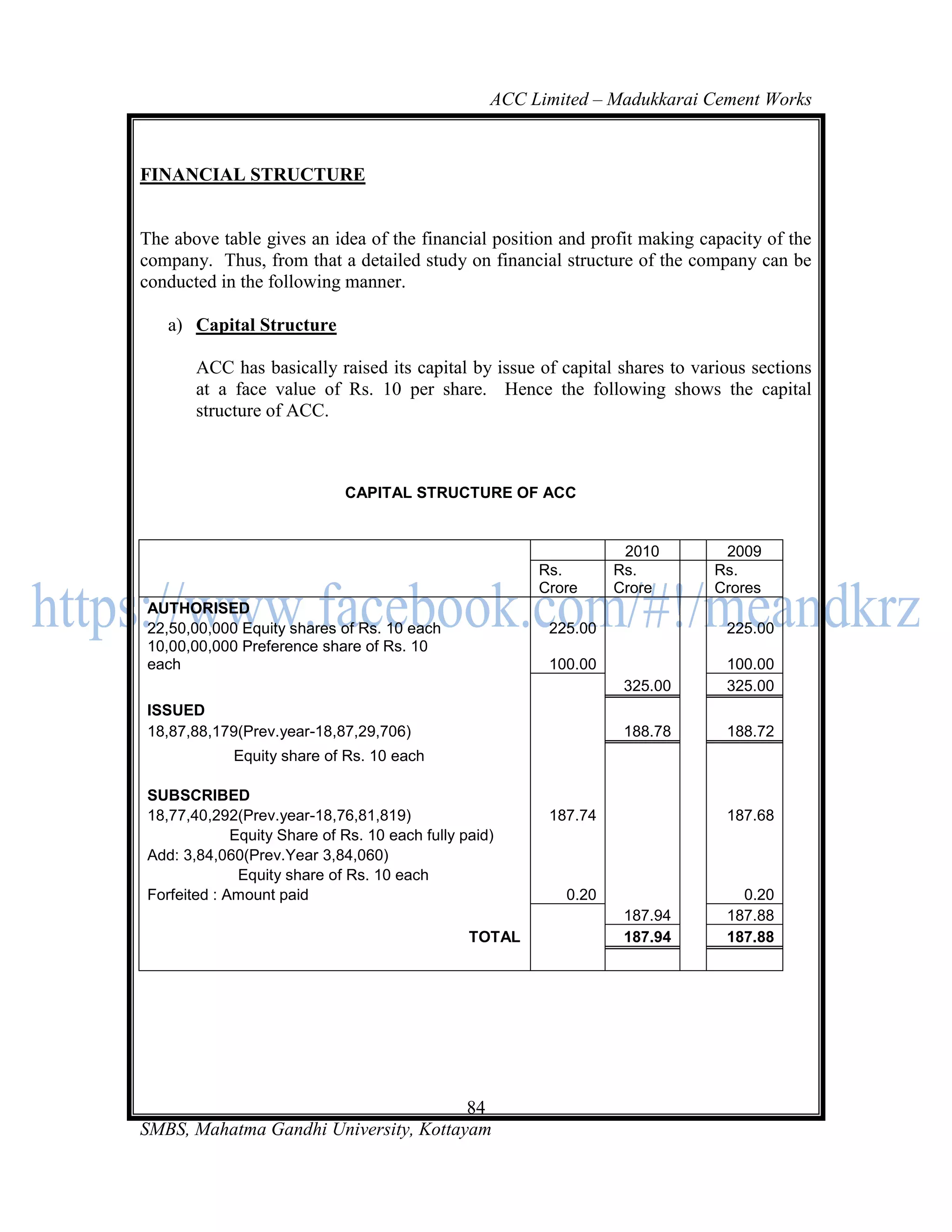

SOURCES OF FINANCE

Financial Policy

Capital structure

Ratio analysis

Leverages

Depreciation policy]

Dividend Policy

Tax Payments

Budgets

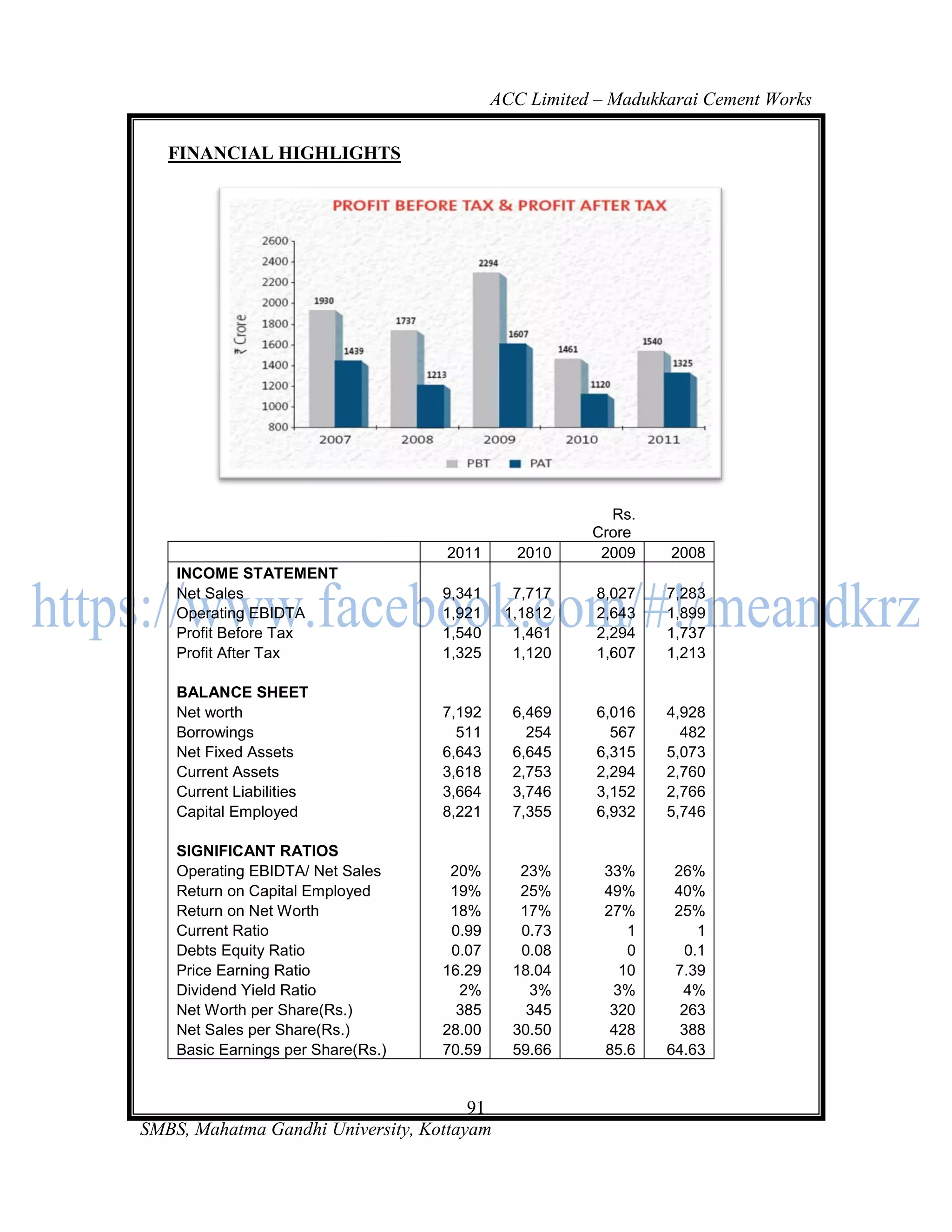

Income statement

90

SMBS, Mahatma Gandhi University, Kottayam](https://image.slidesharecdn.com/acclimitedbychrisjose-120626042925-phpapp02/75/Acc-limitedbychris-jose-90-2048.jpg)

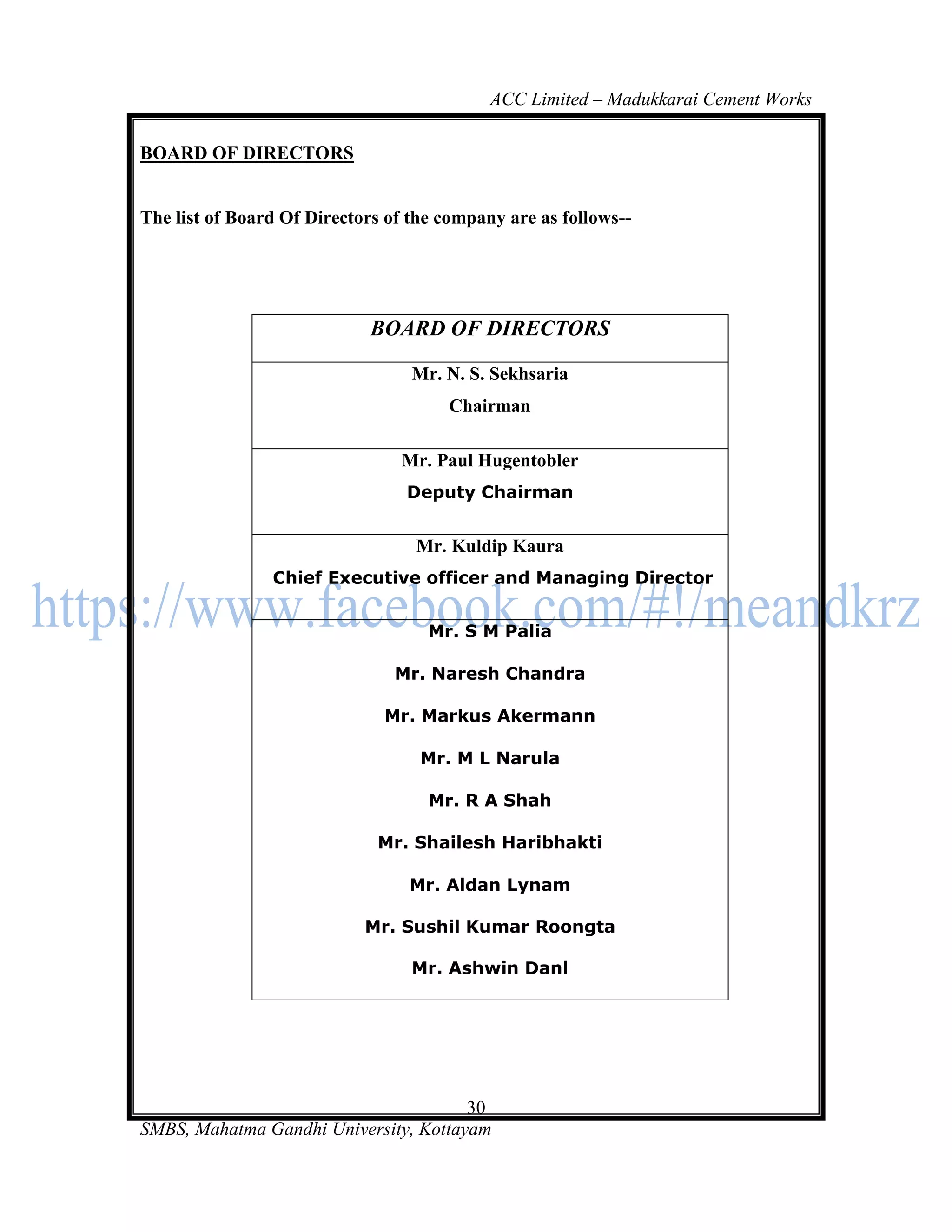

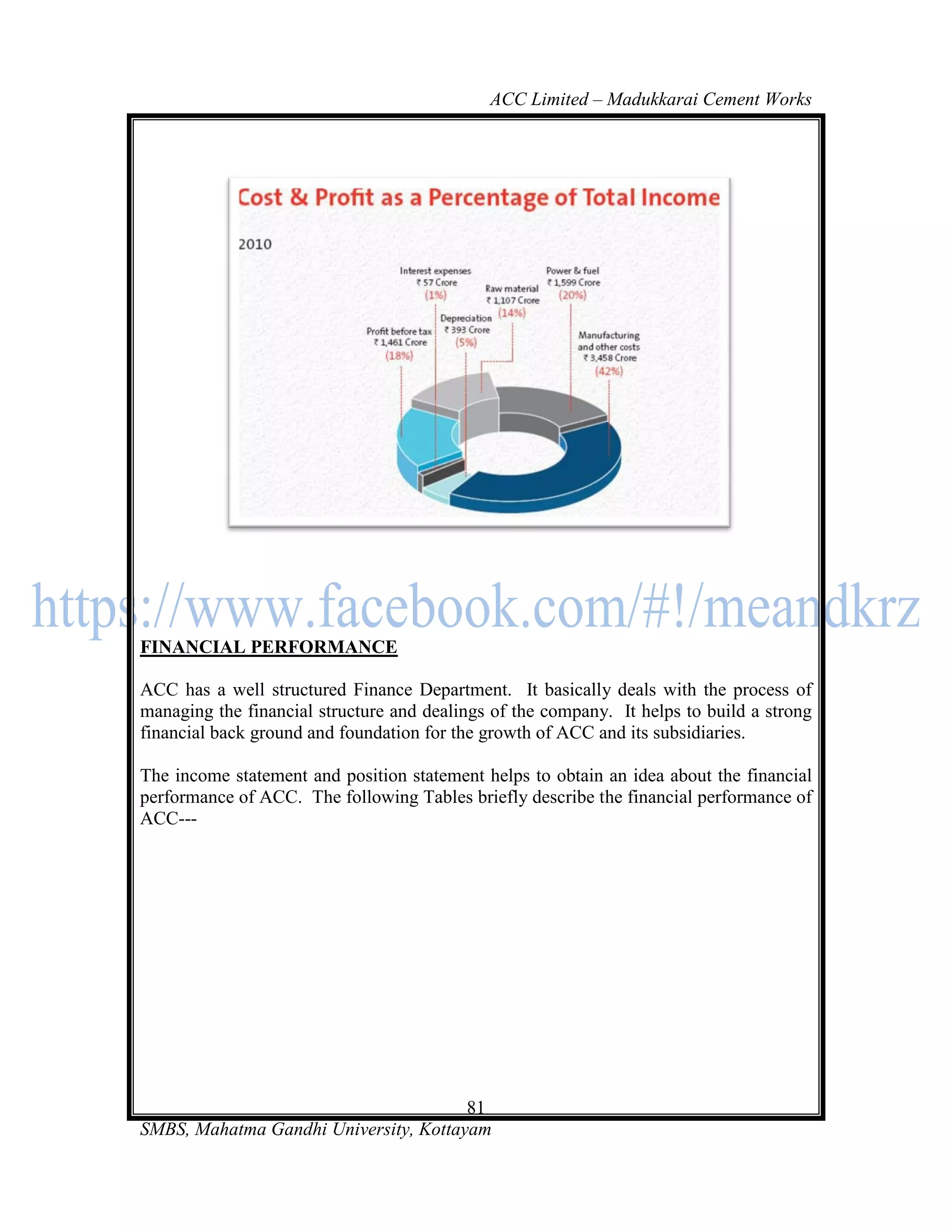

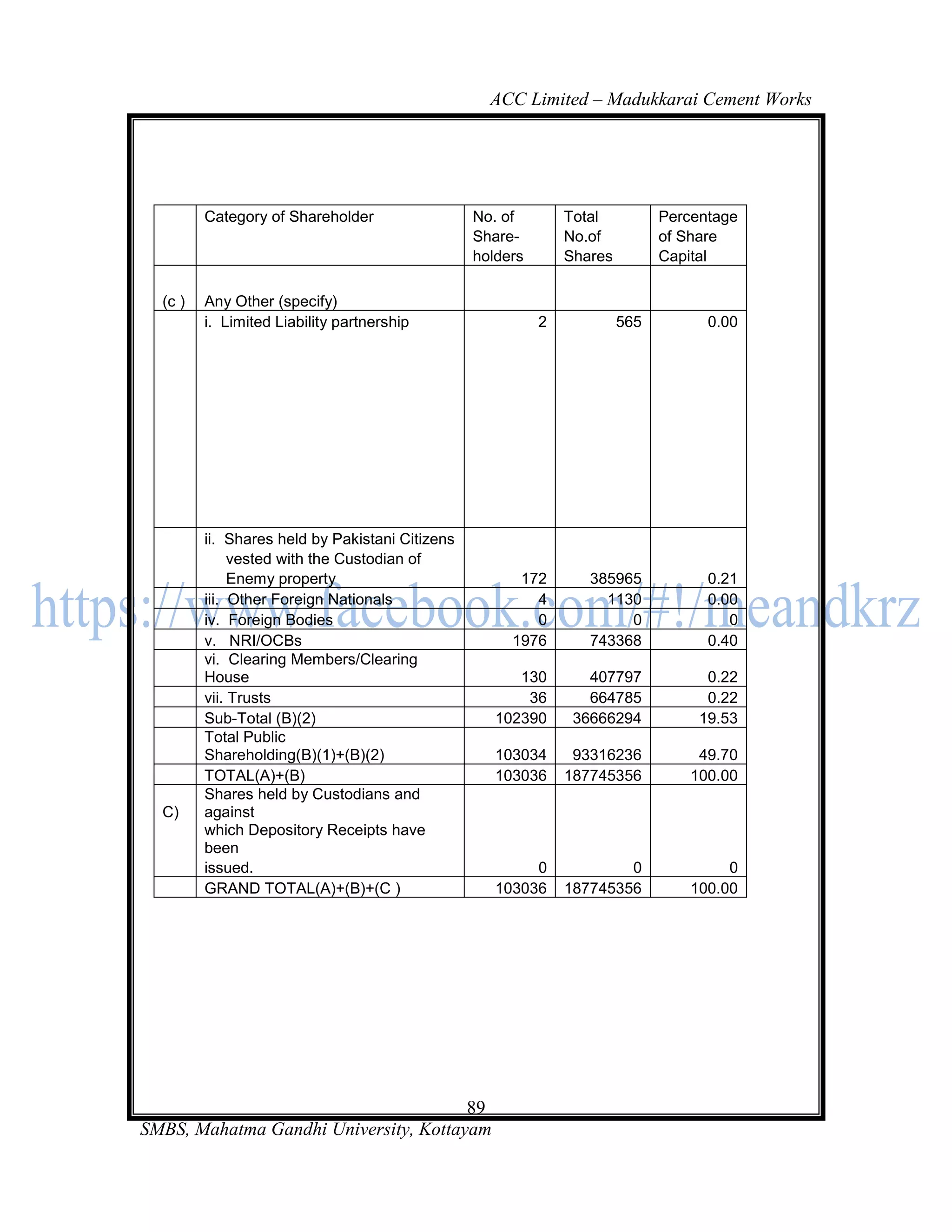

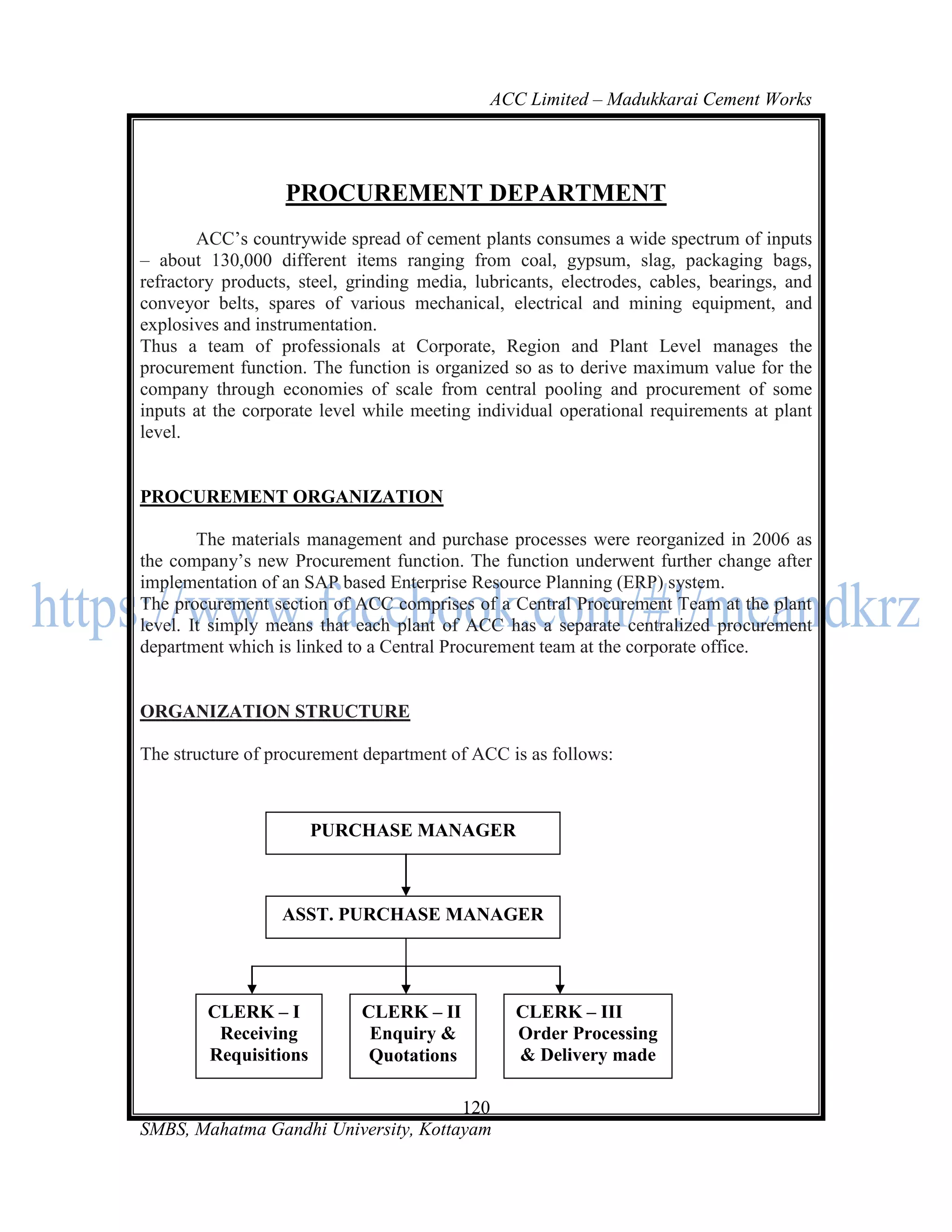

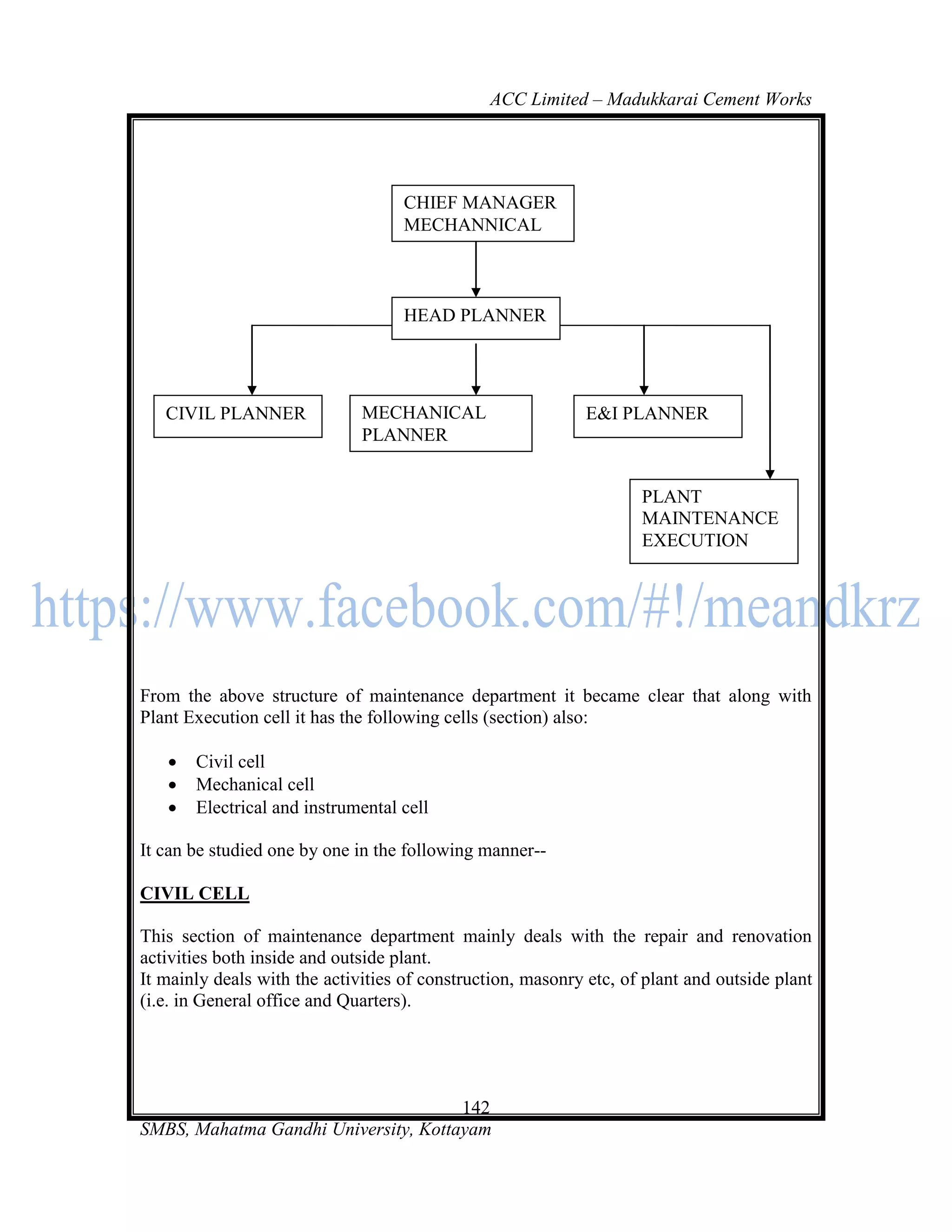

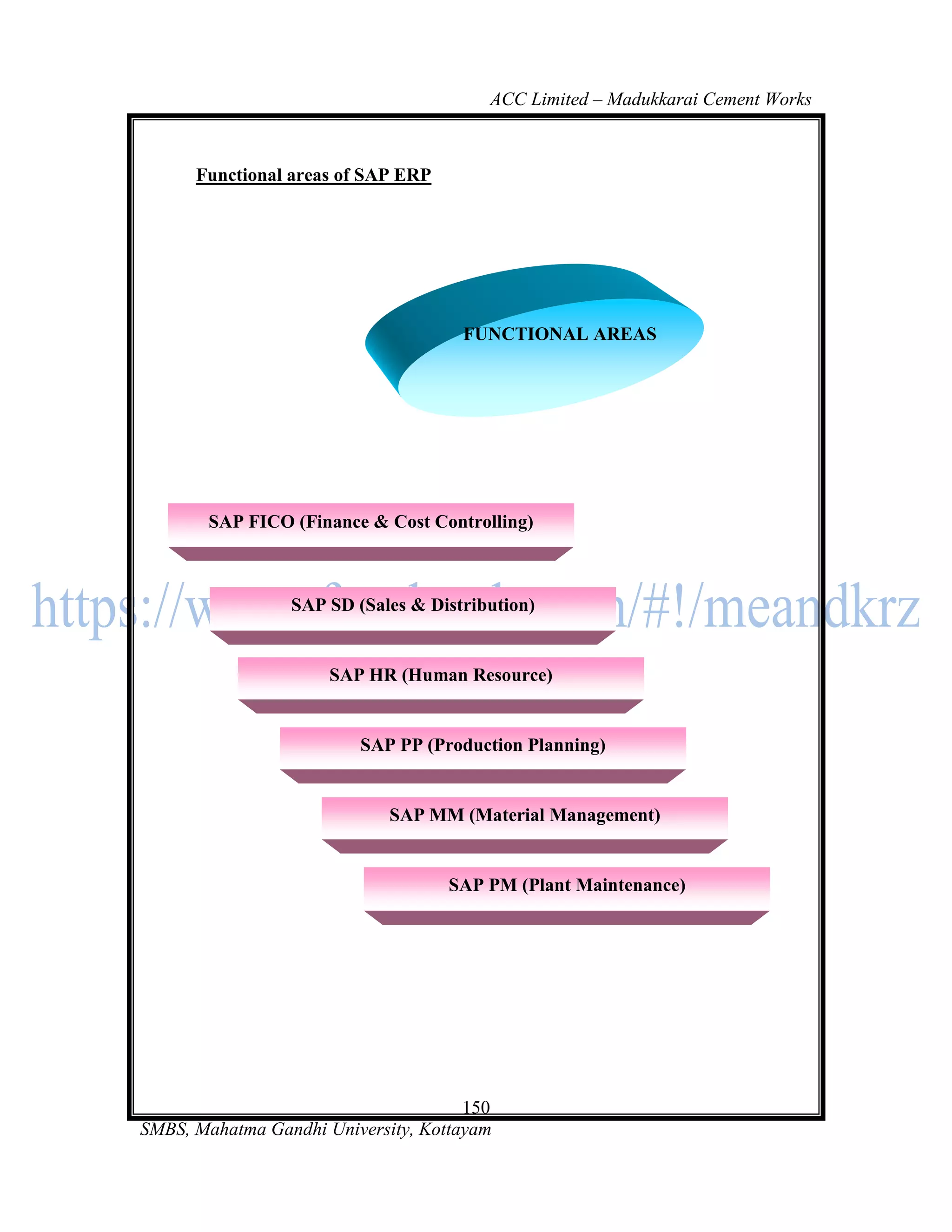

![ACC Limited – Madukkarai Cement Works

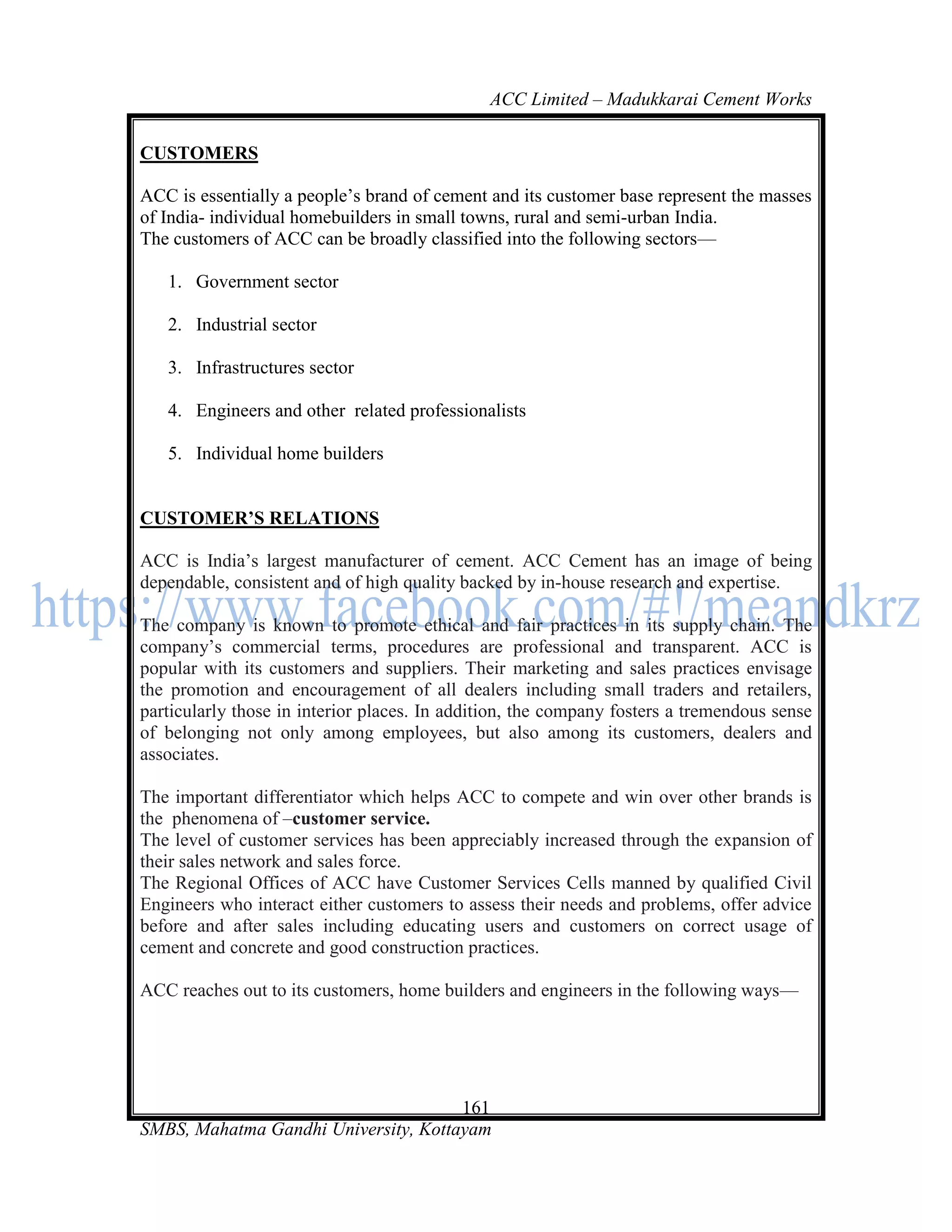

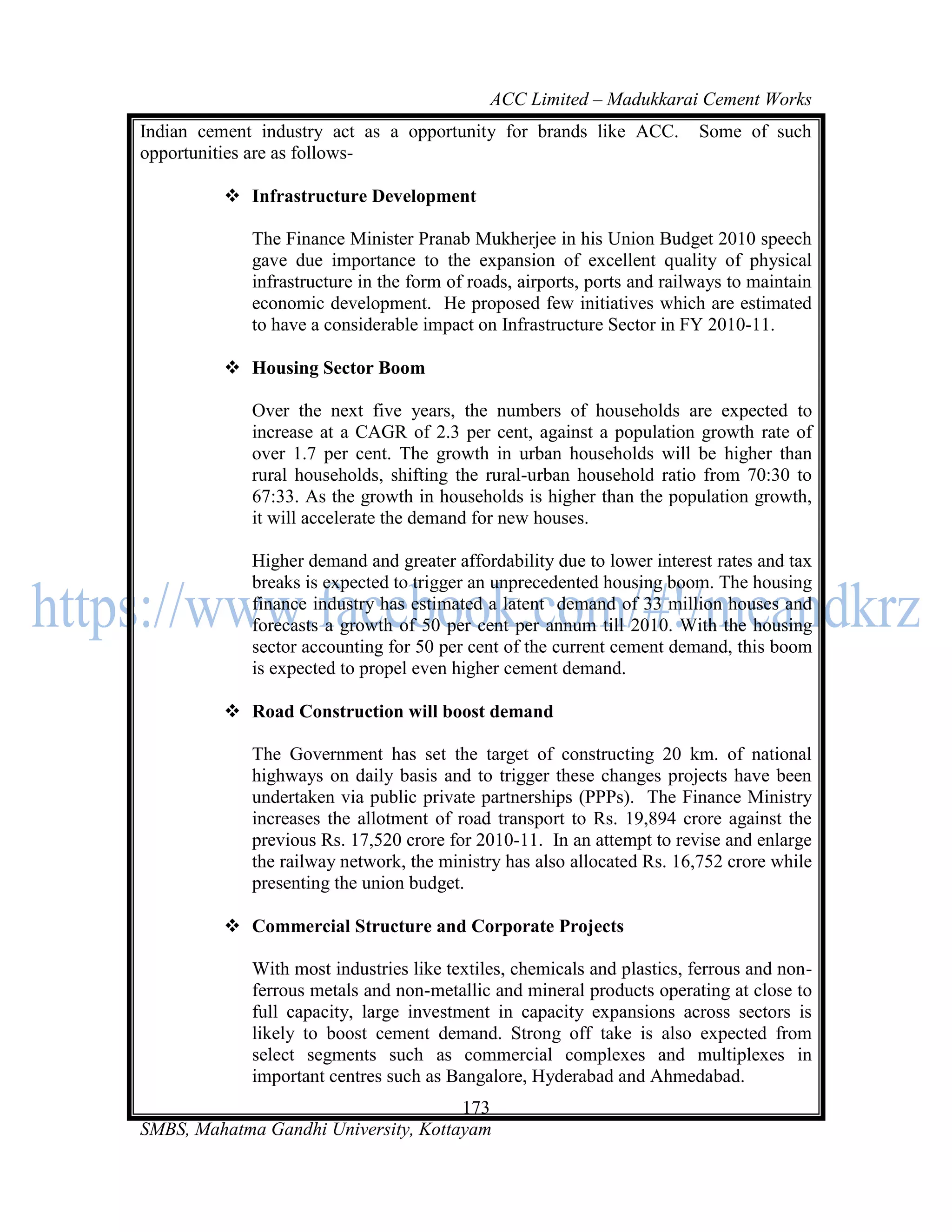

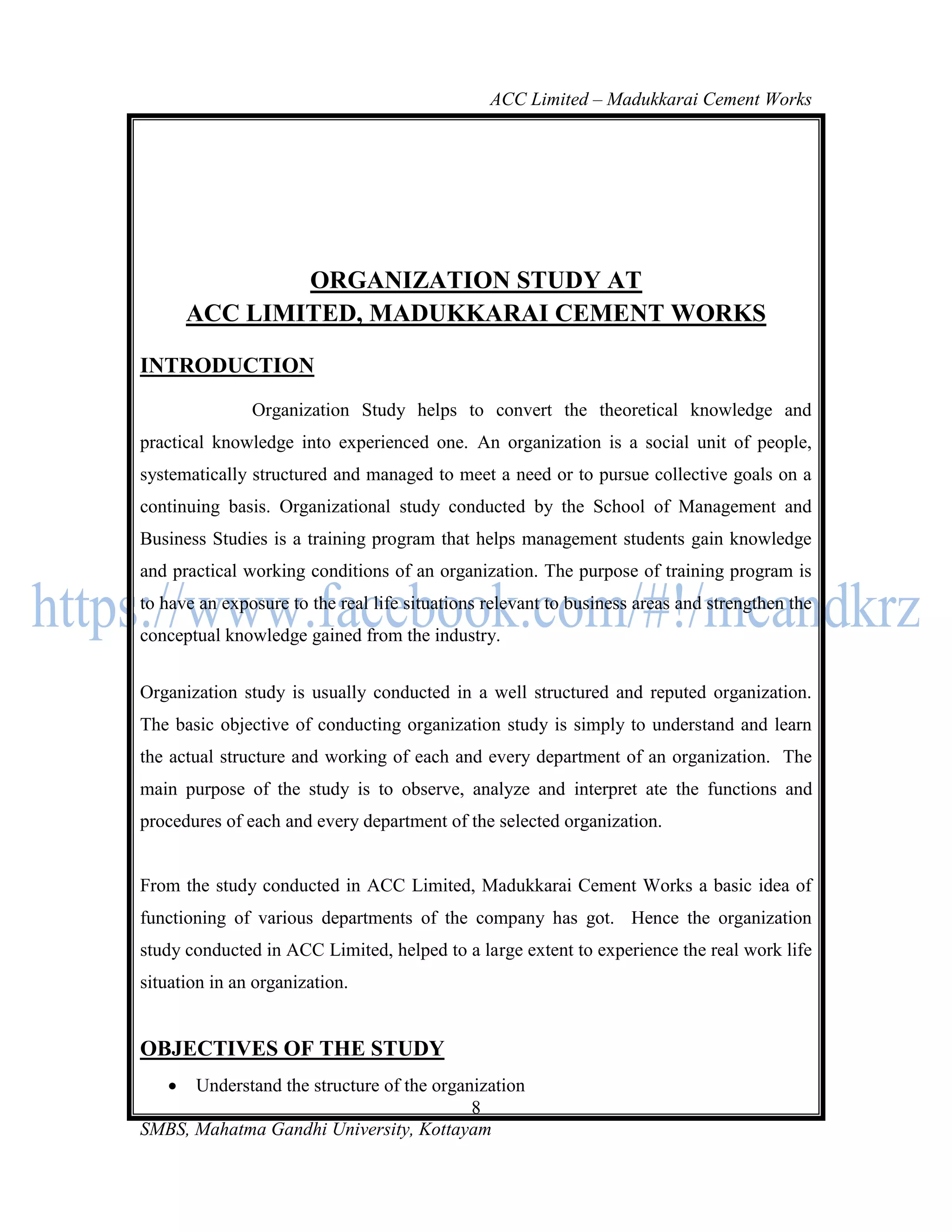

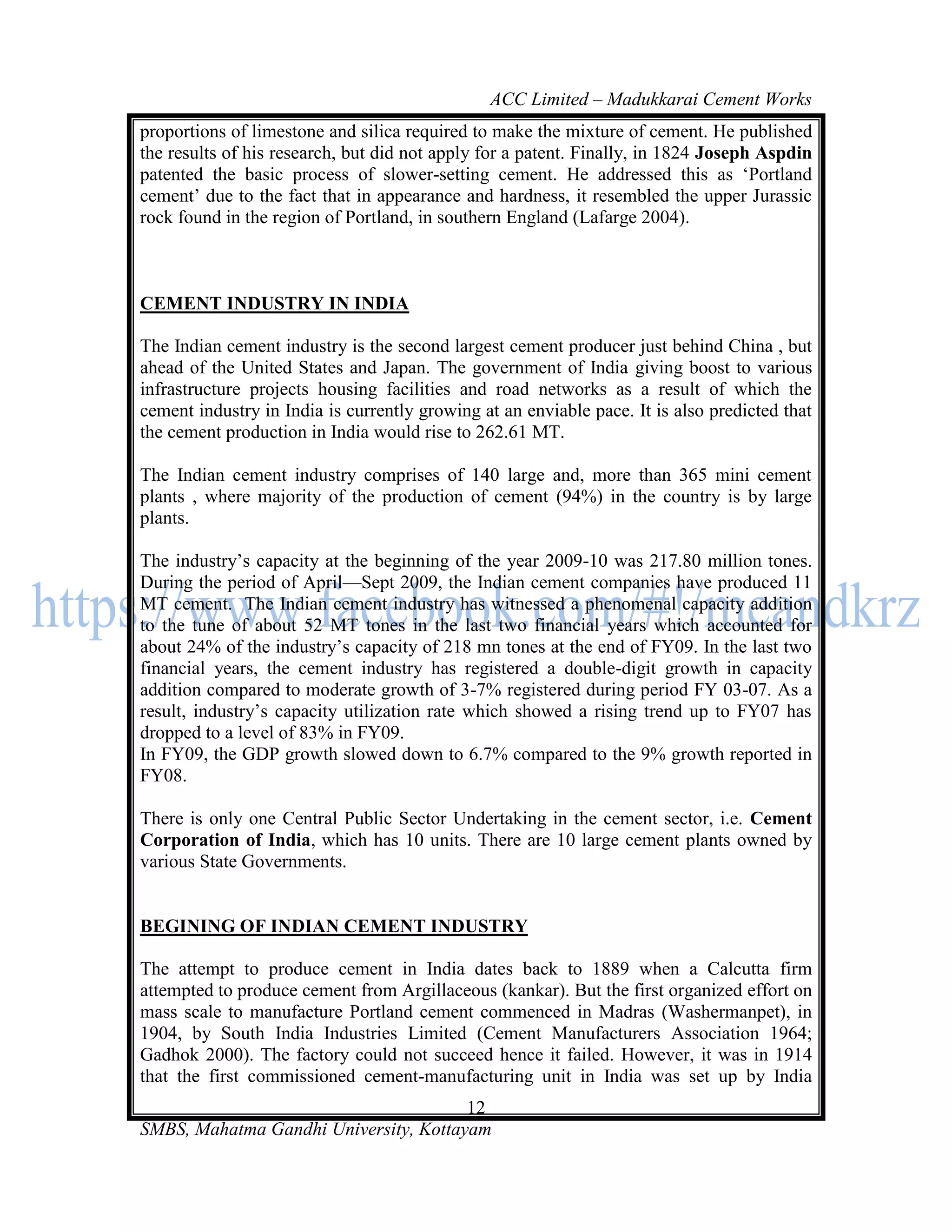

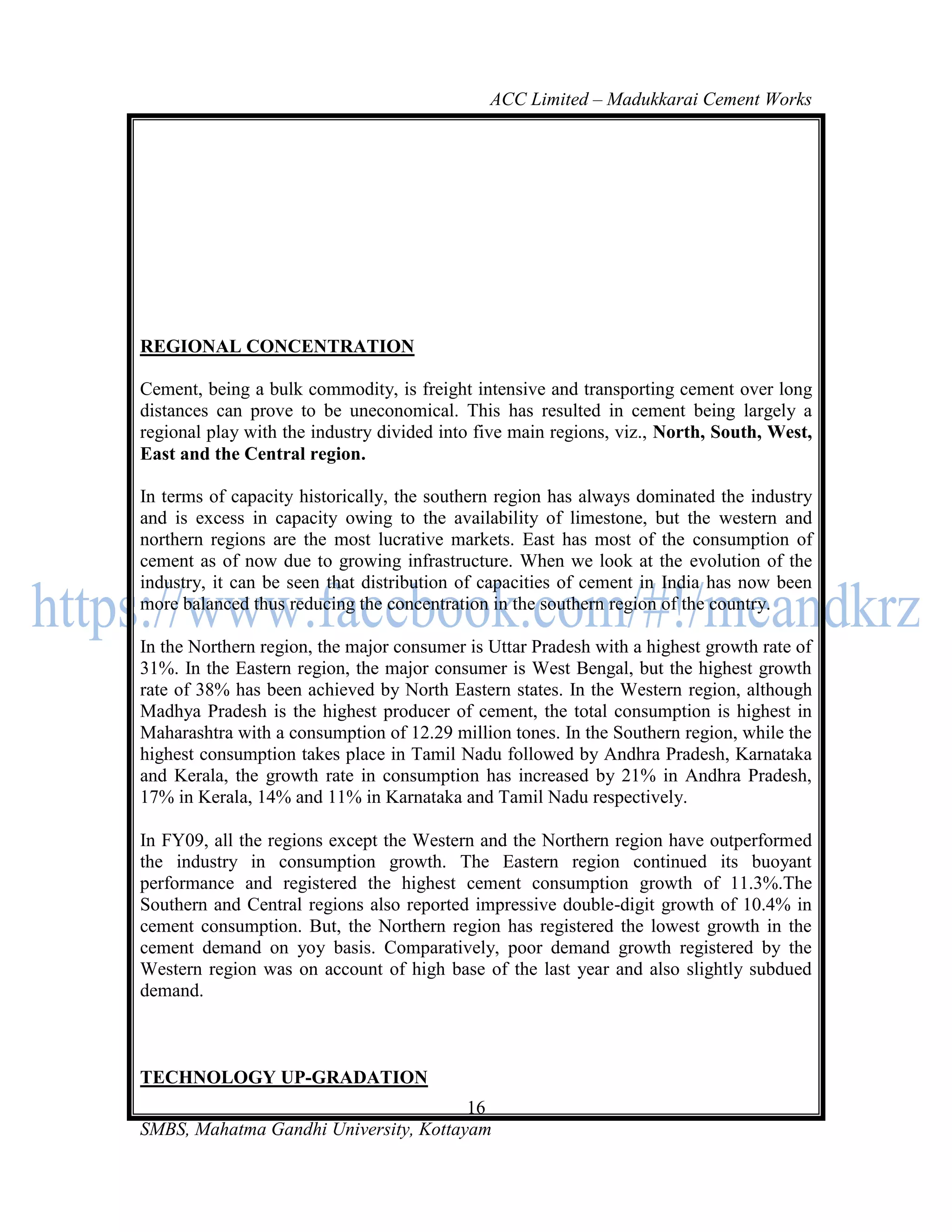

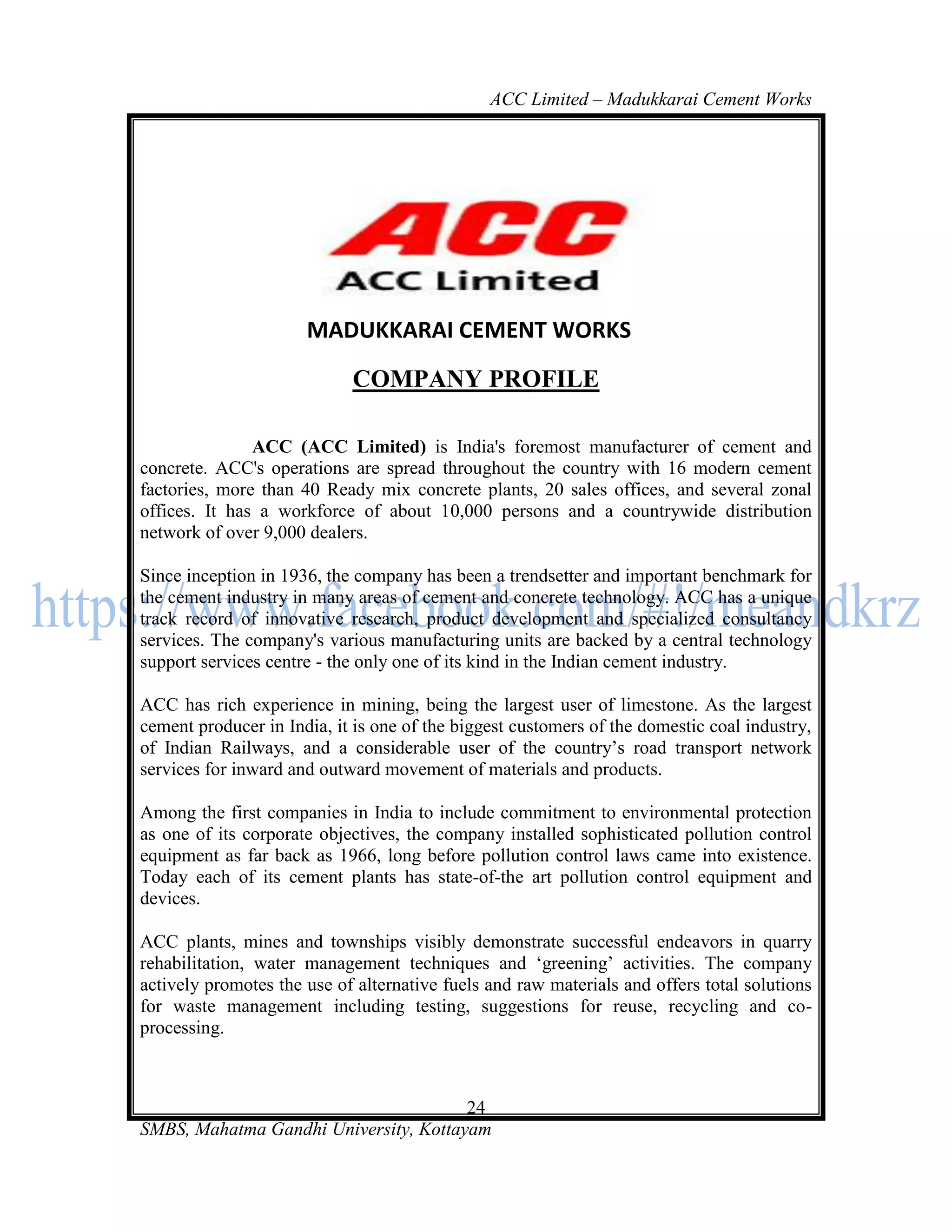

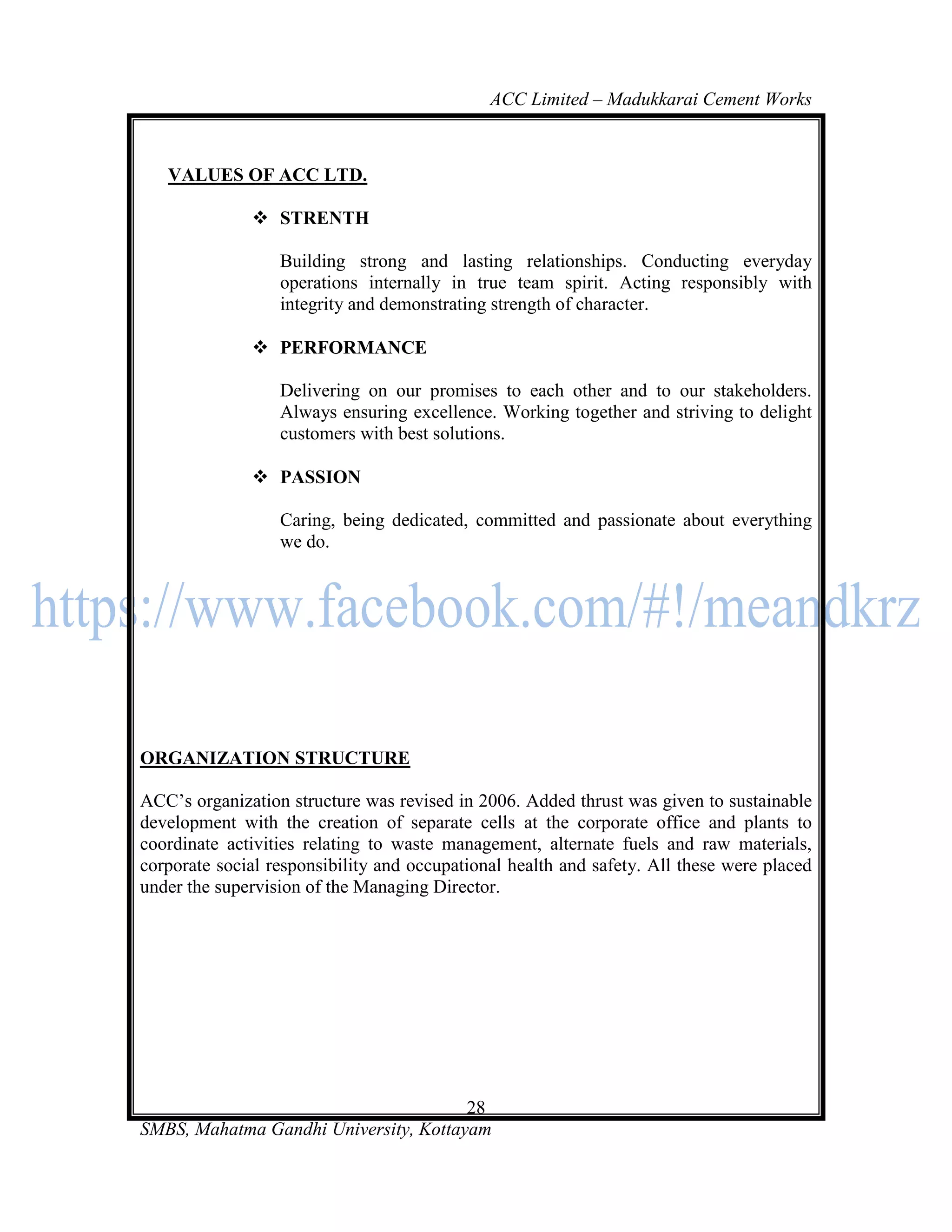

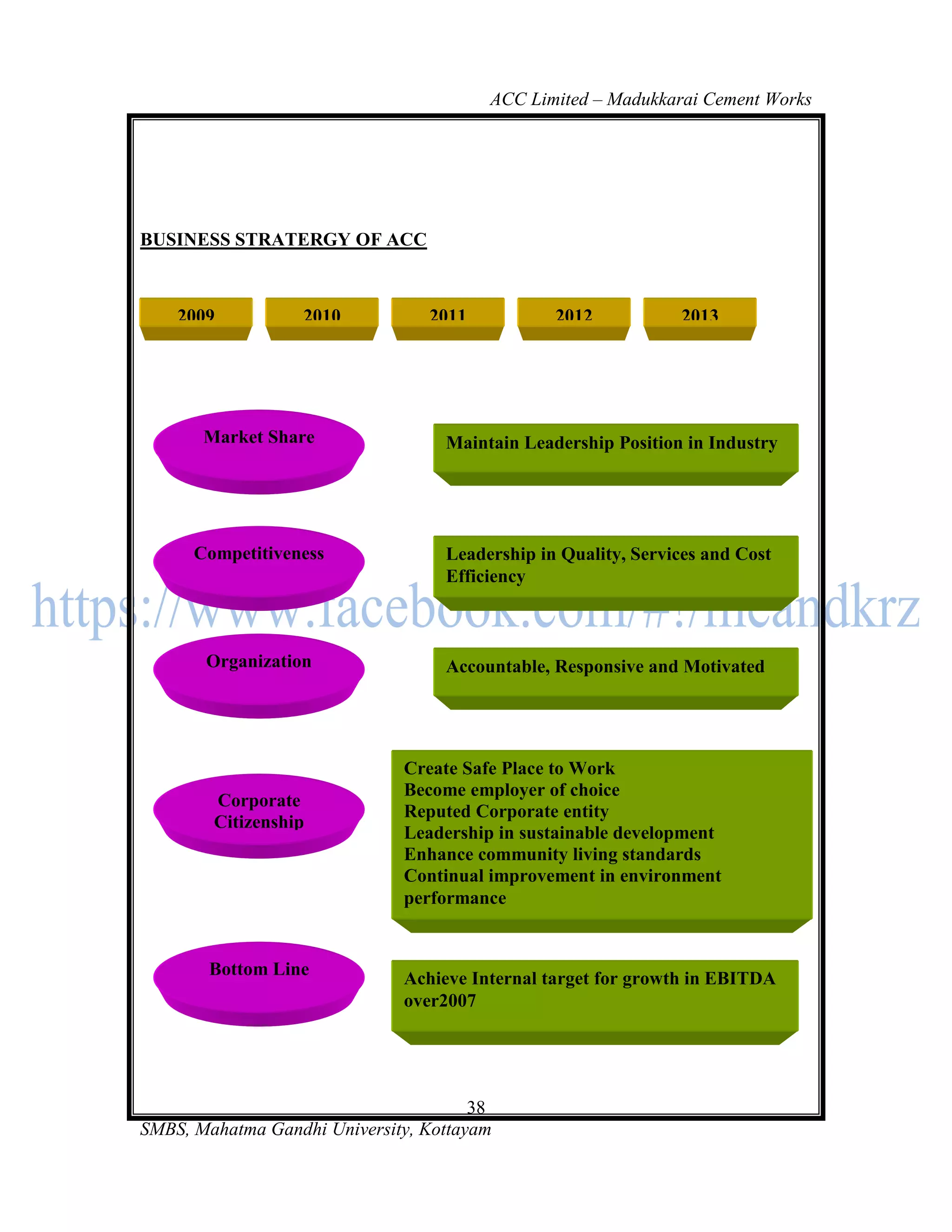

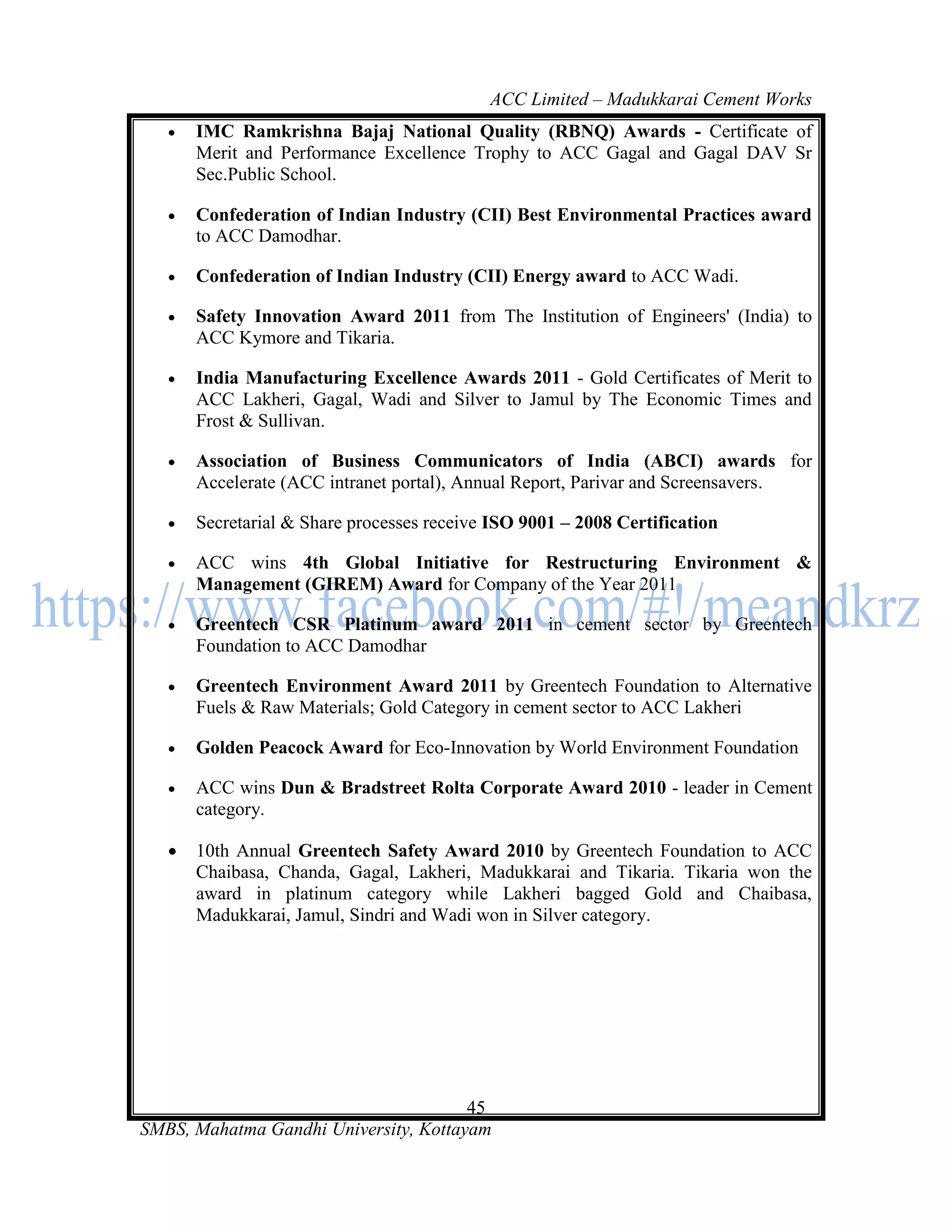

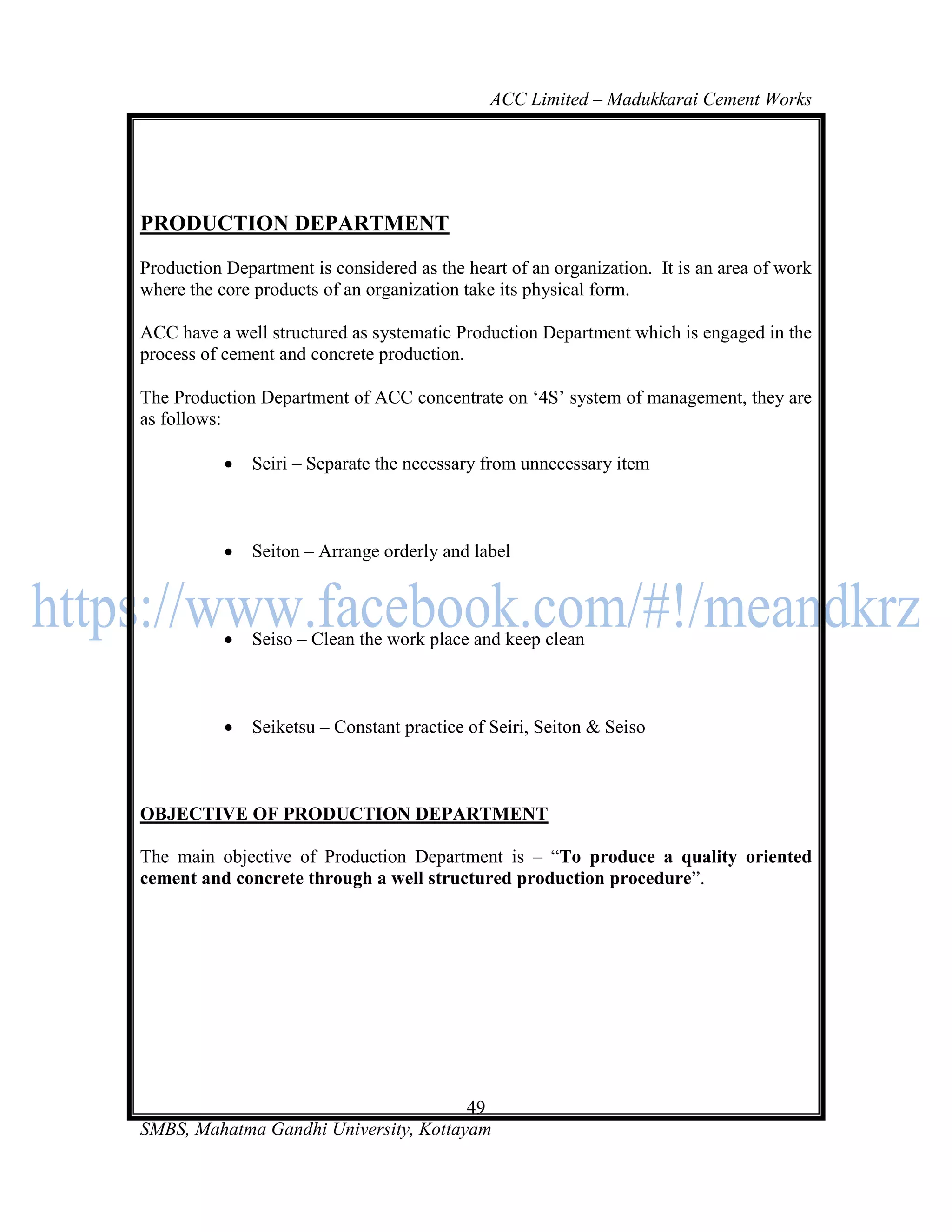

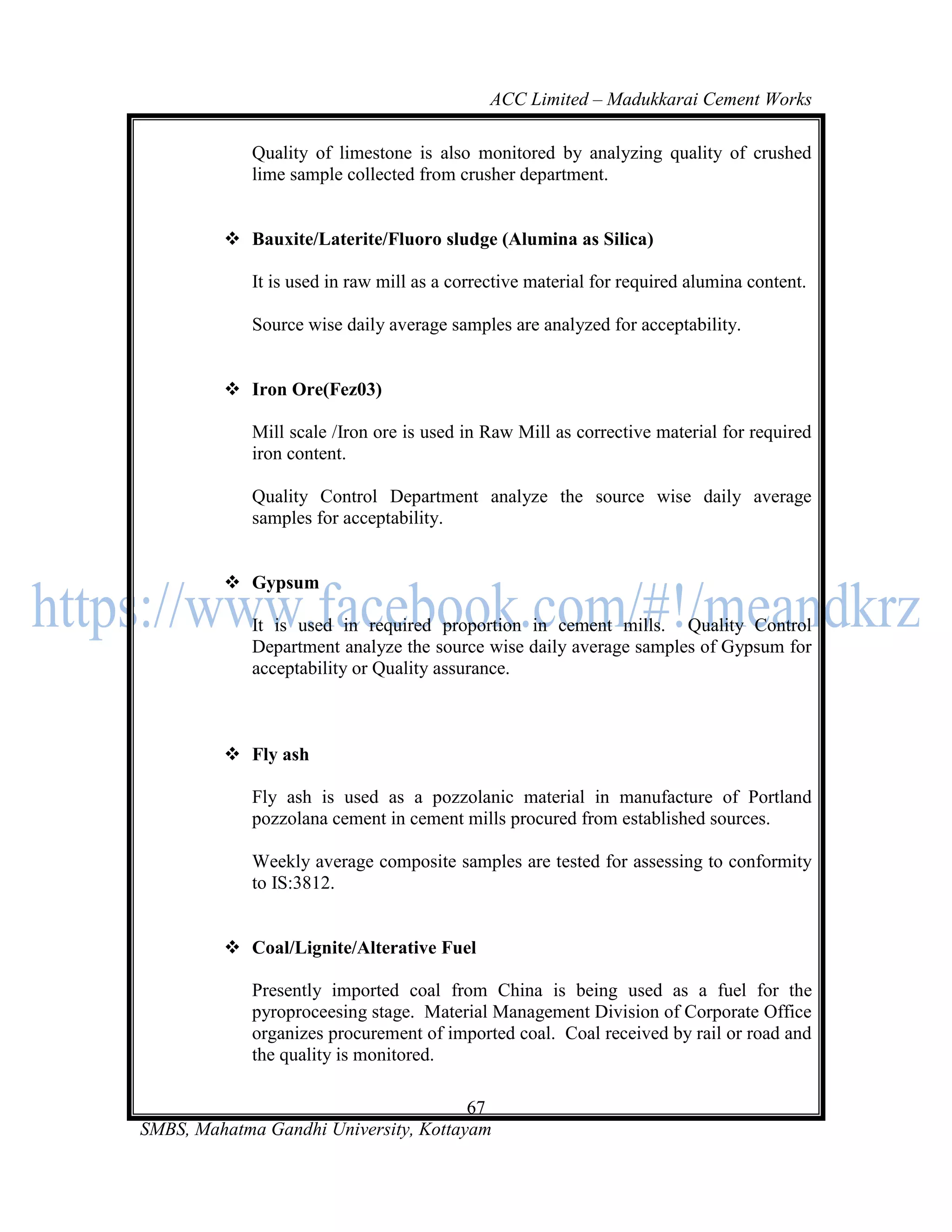

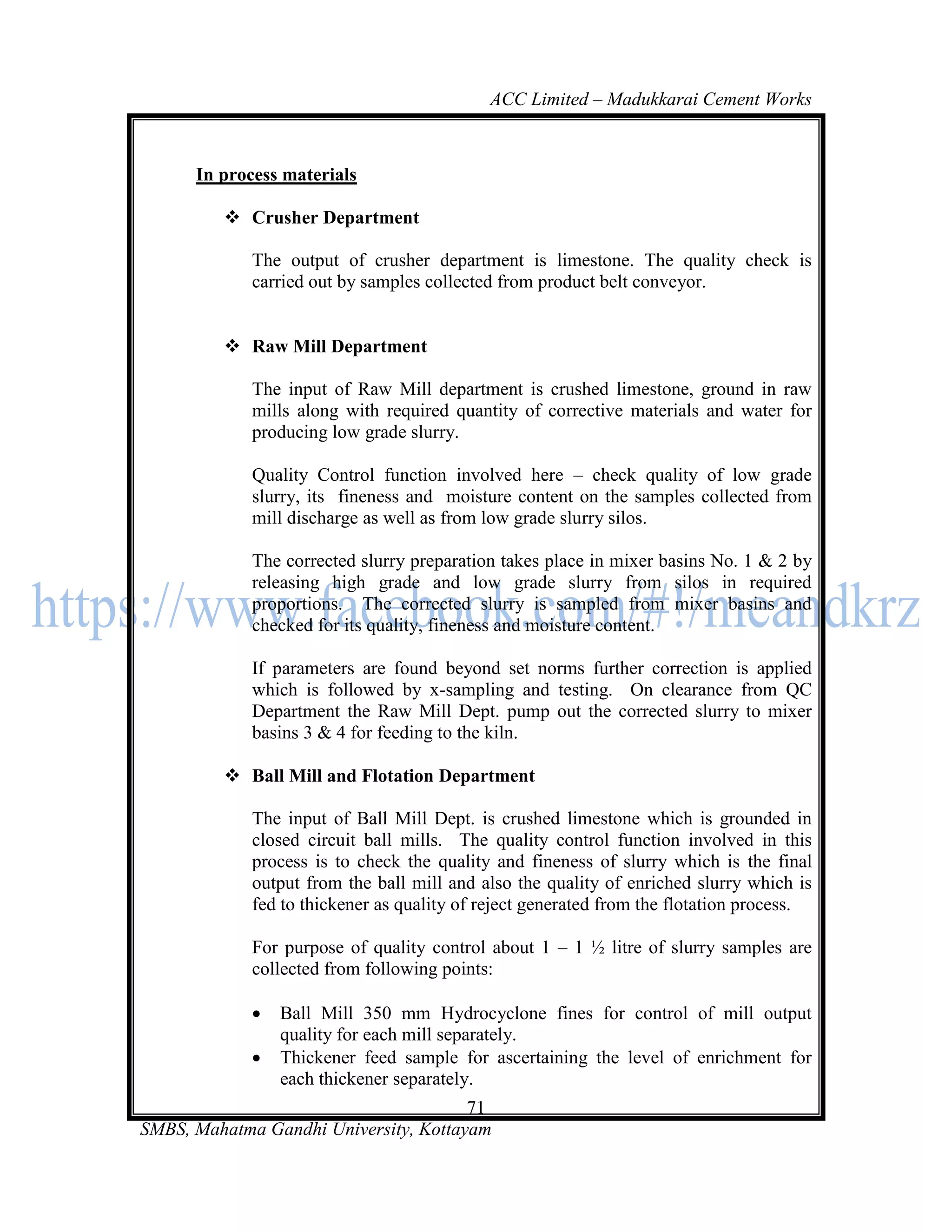

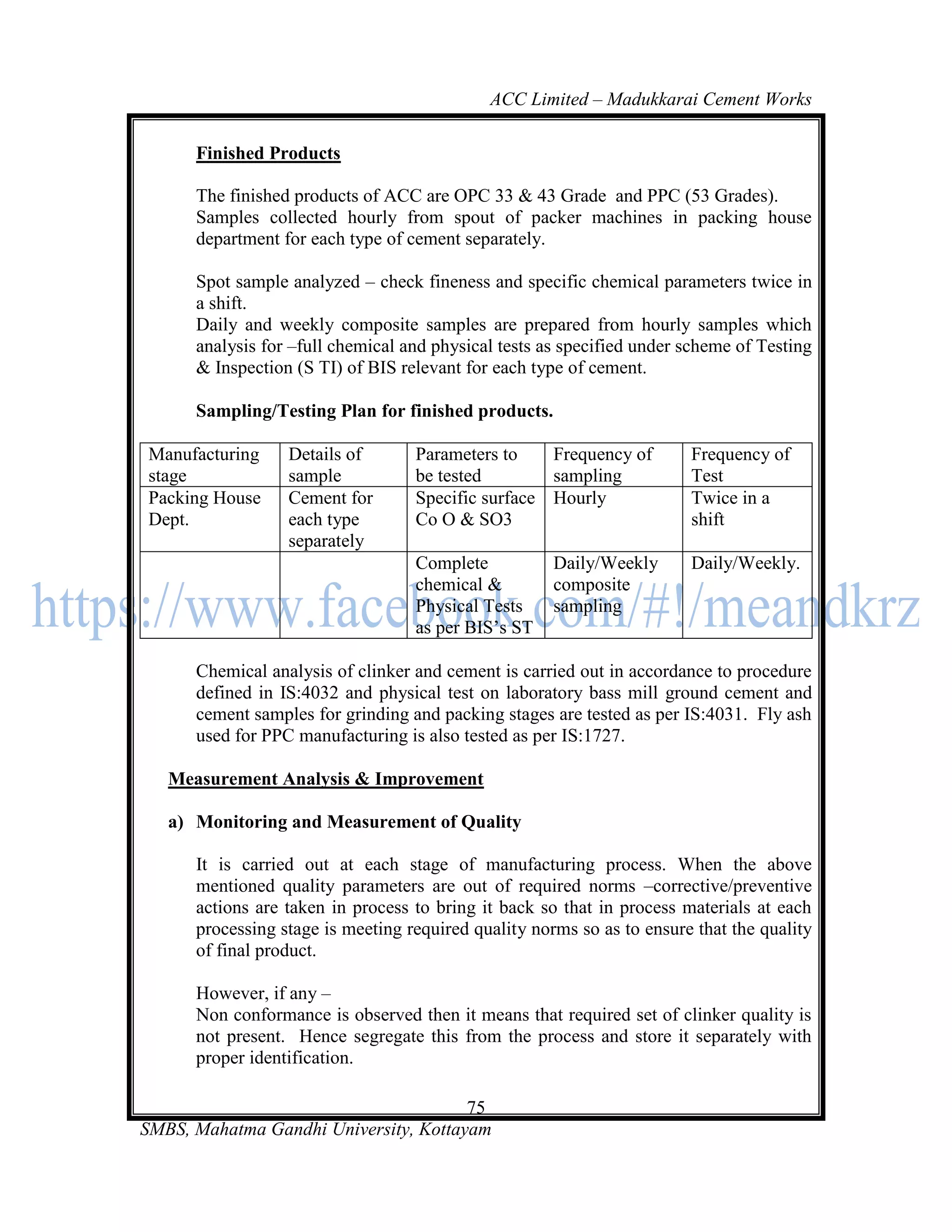

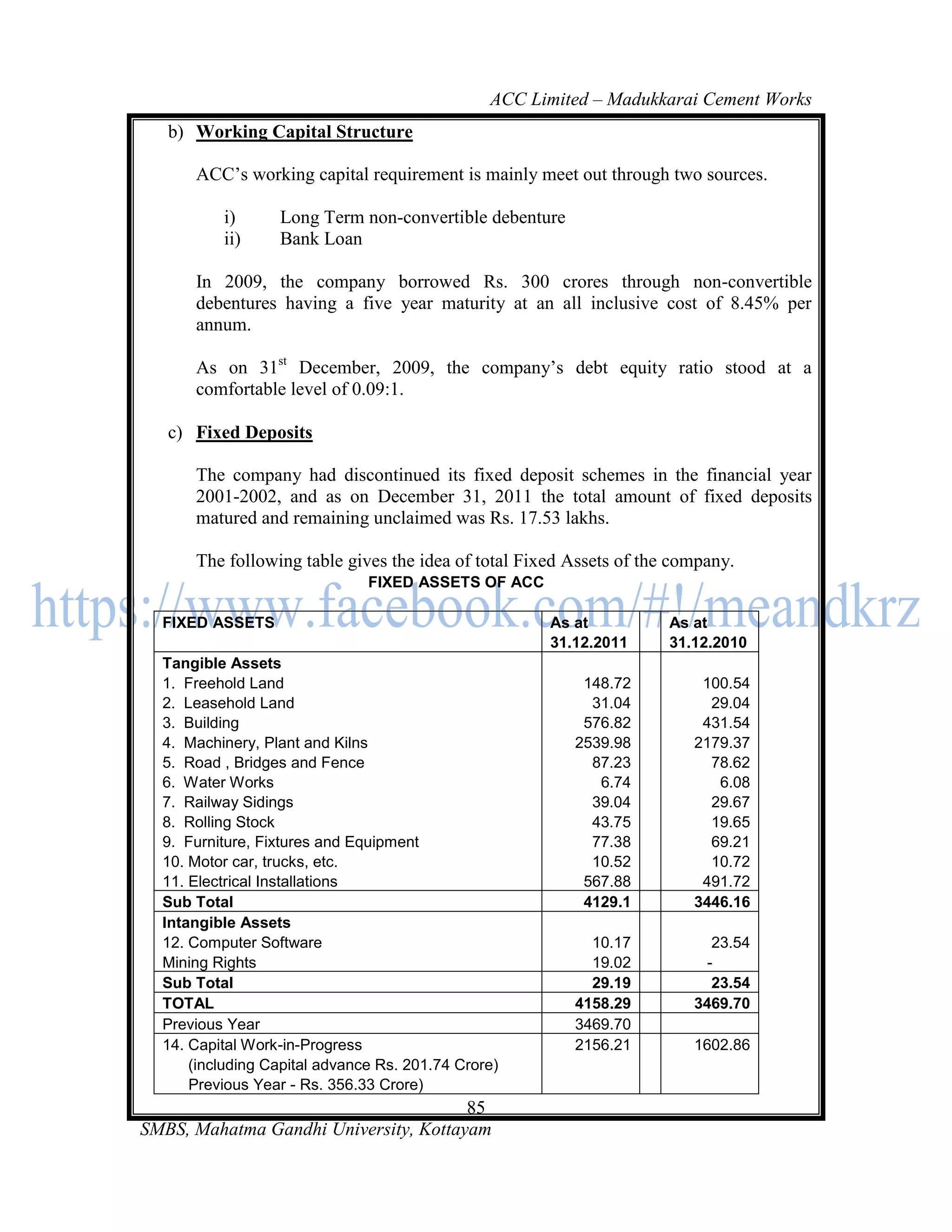

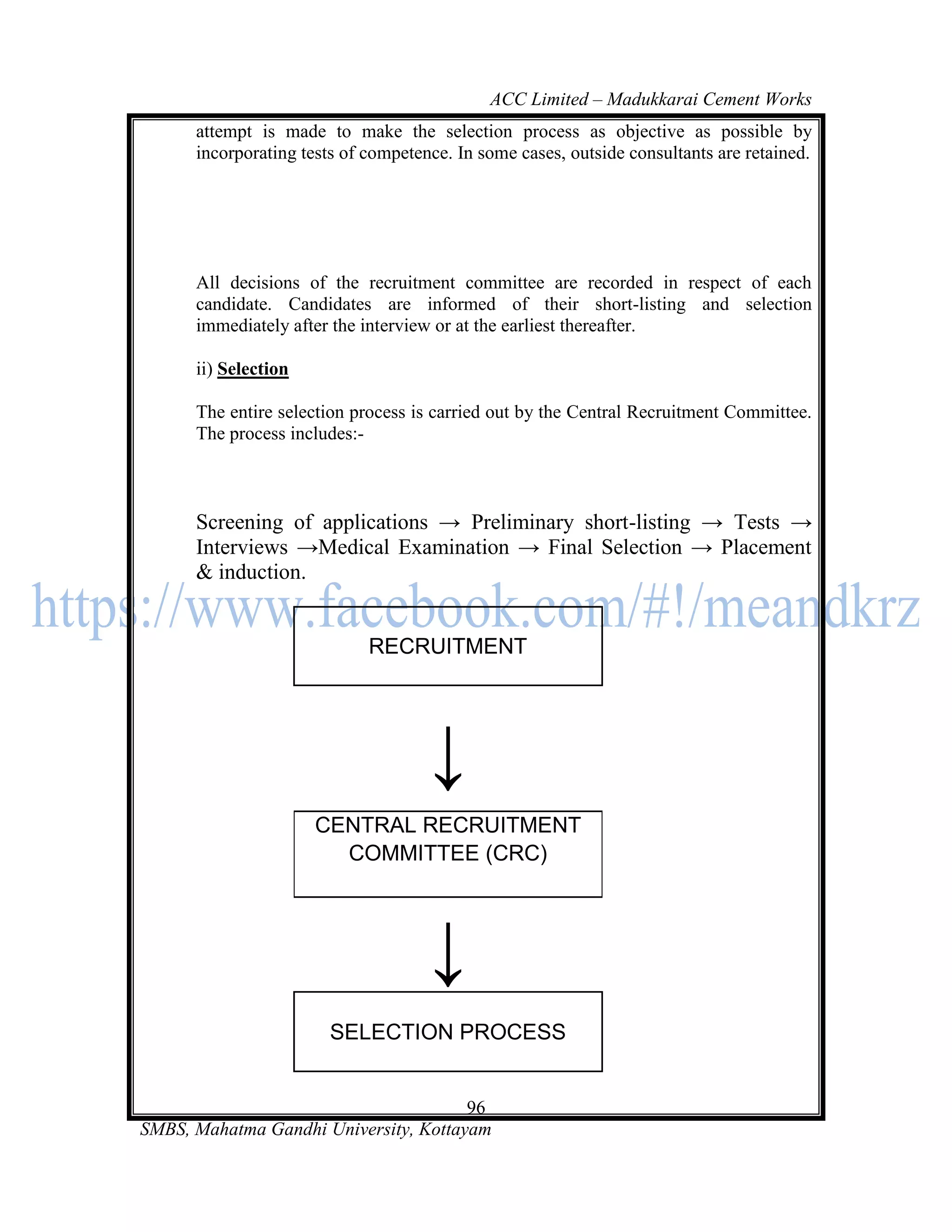

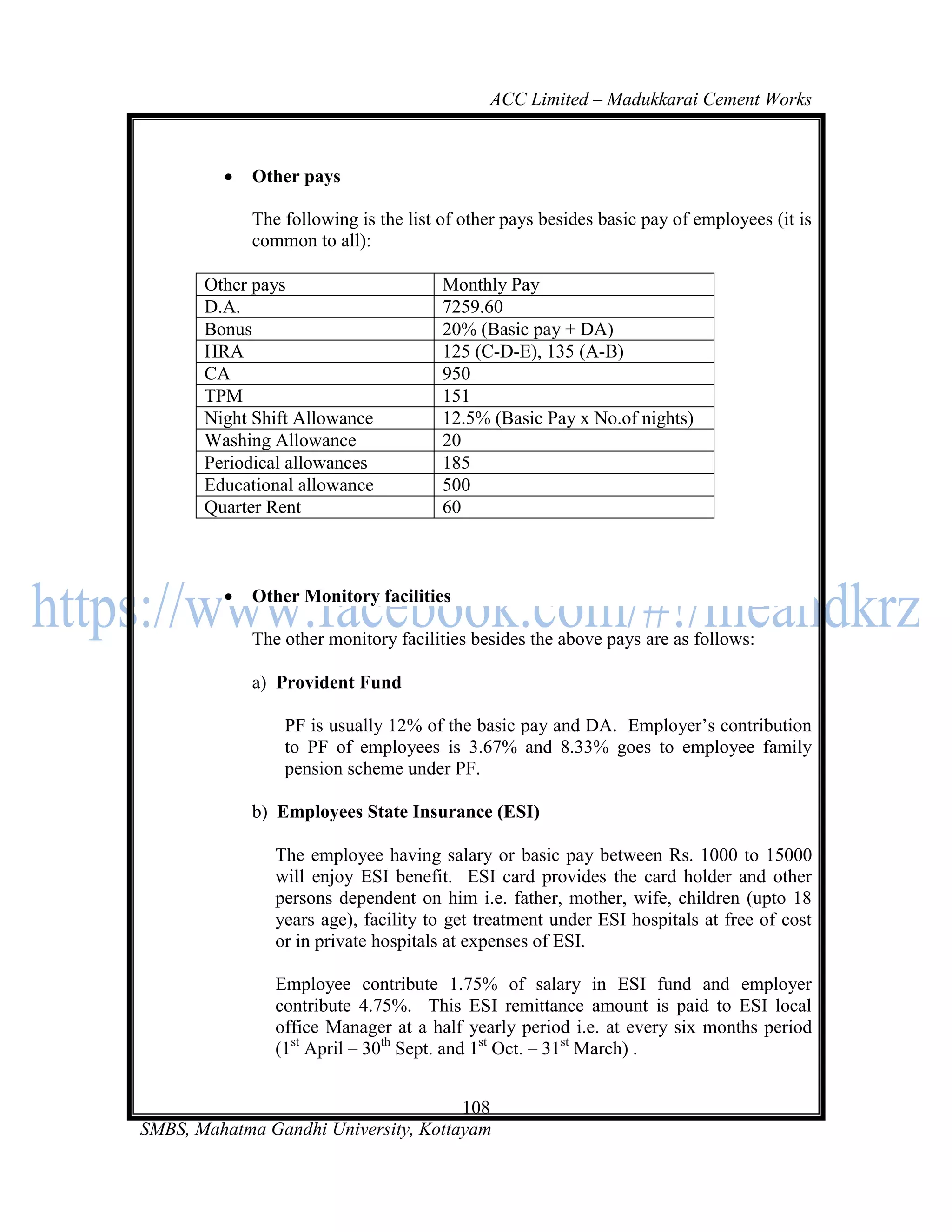

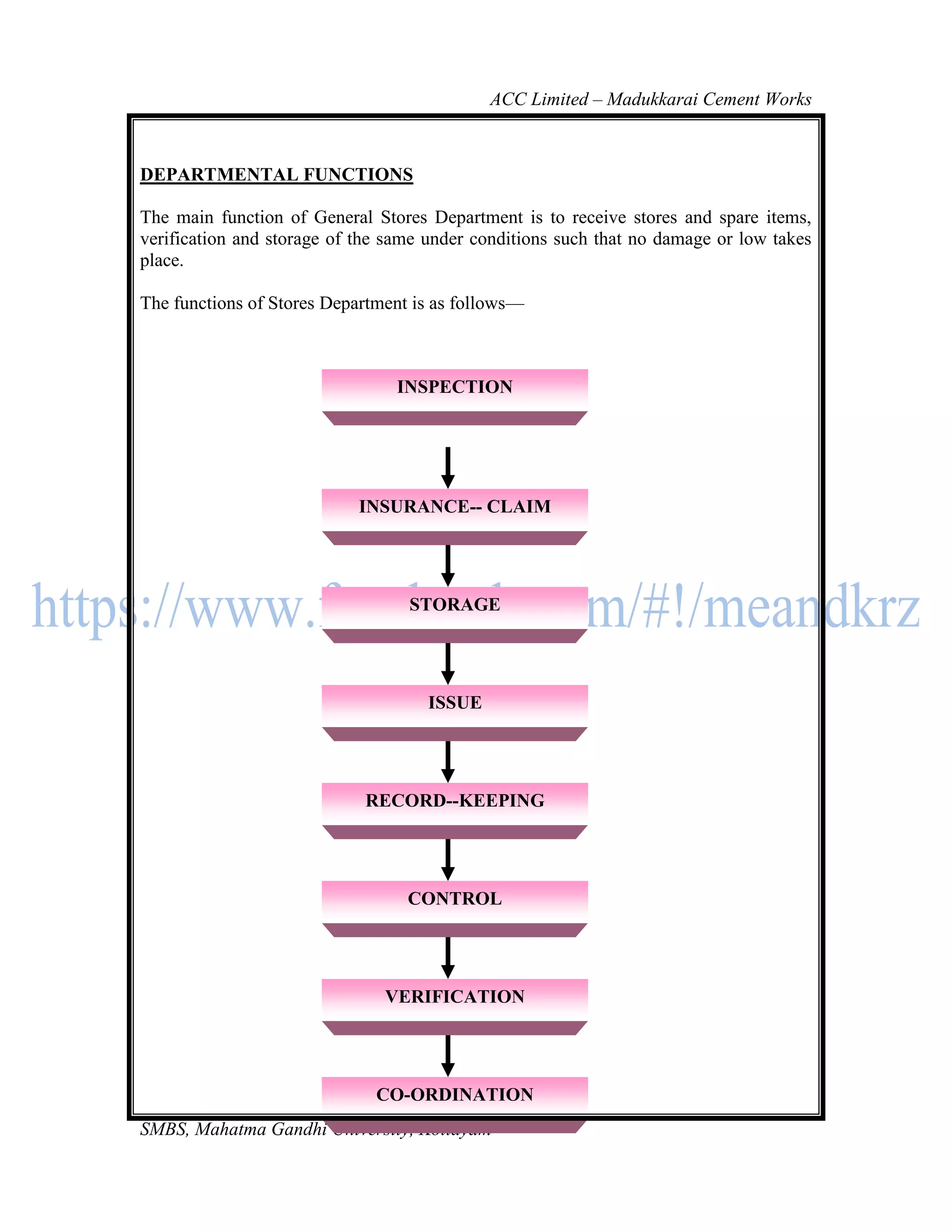

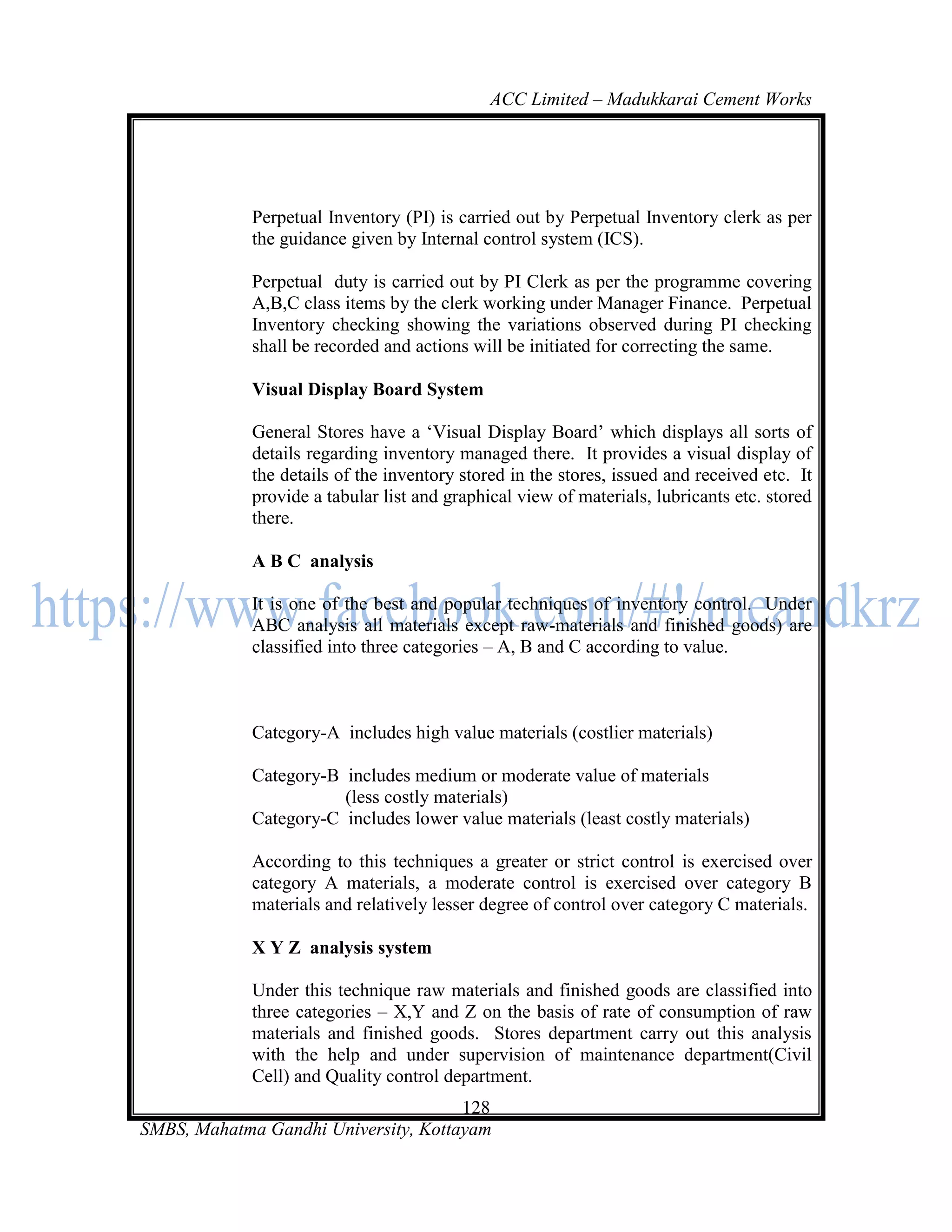

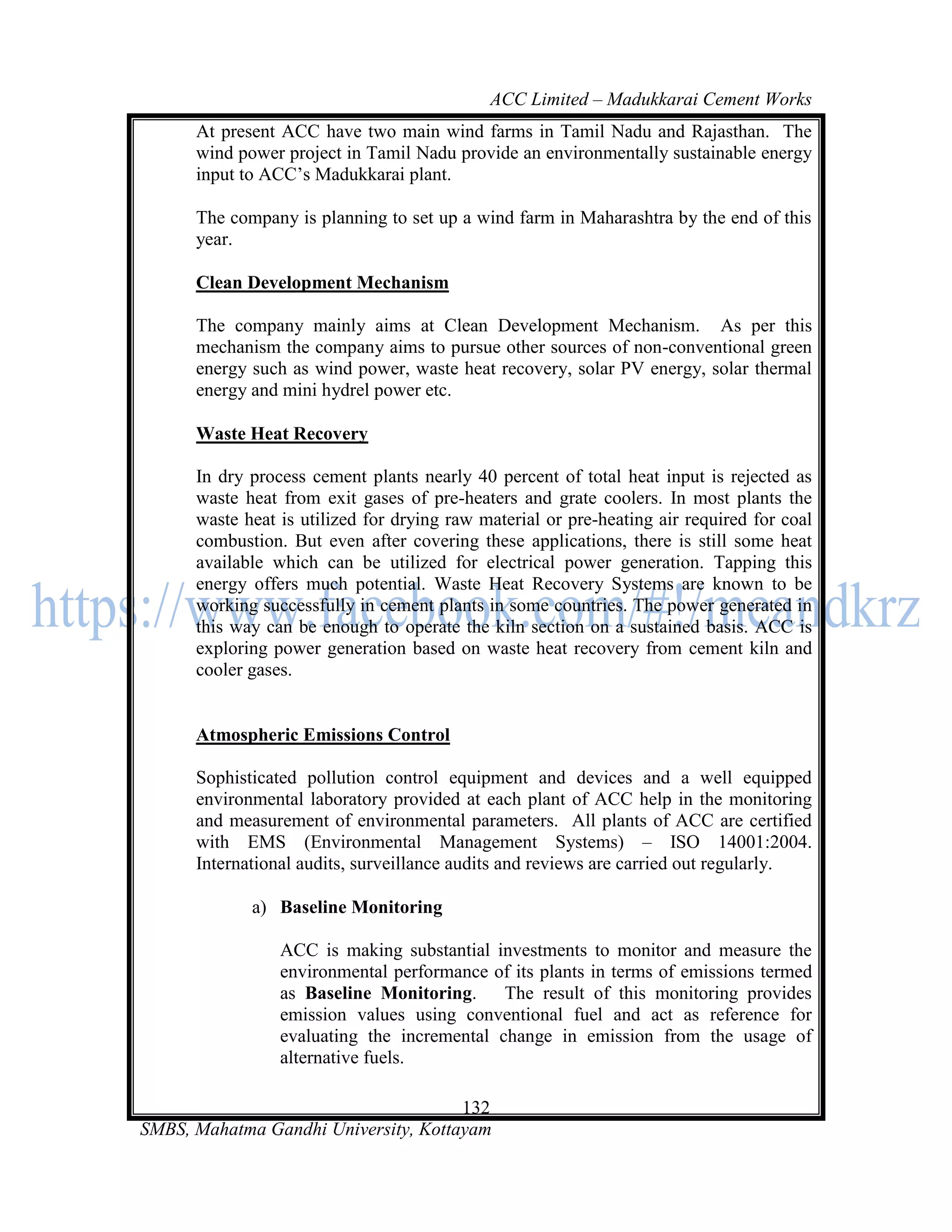

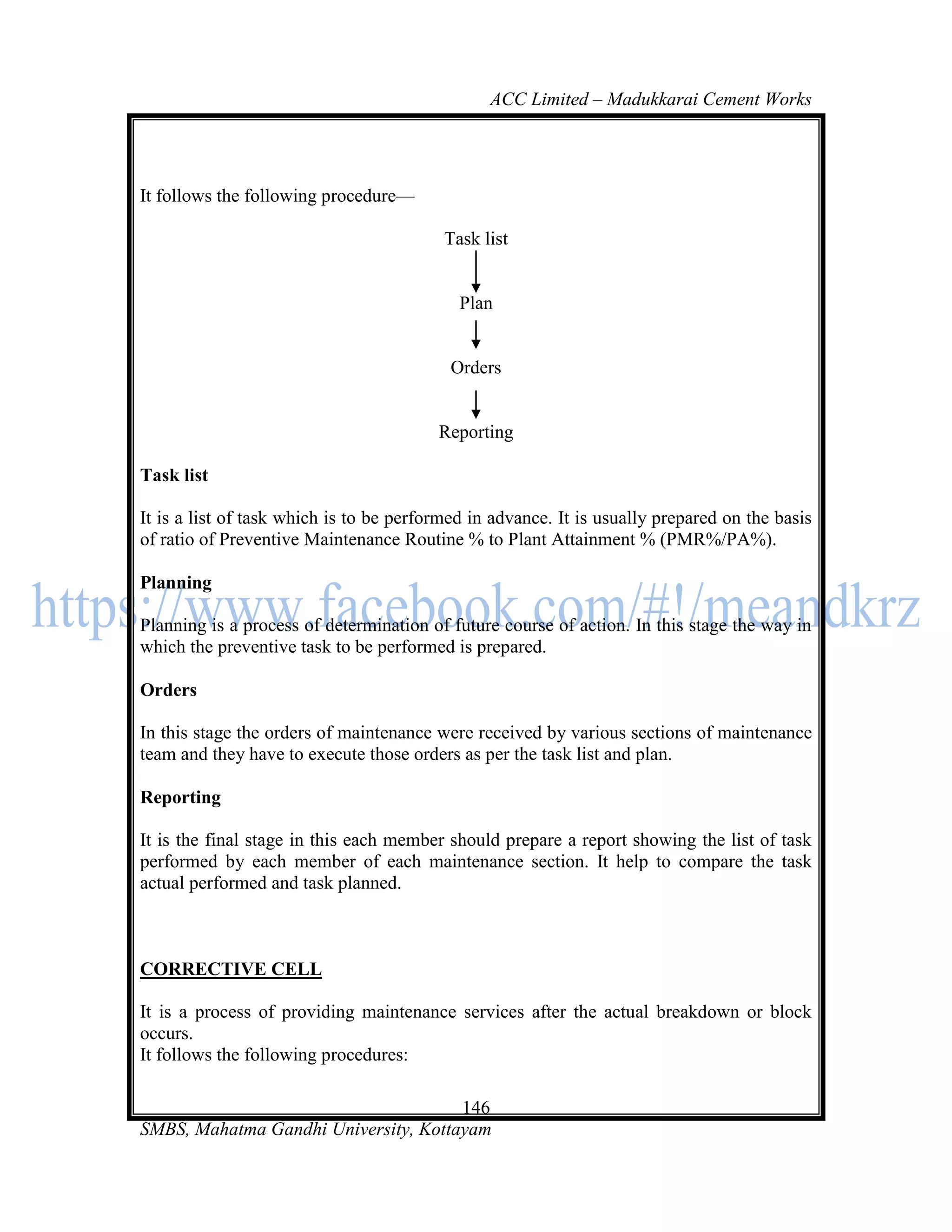

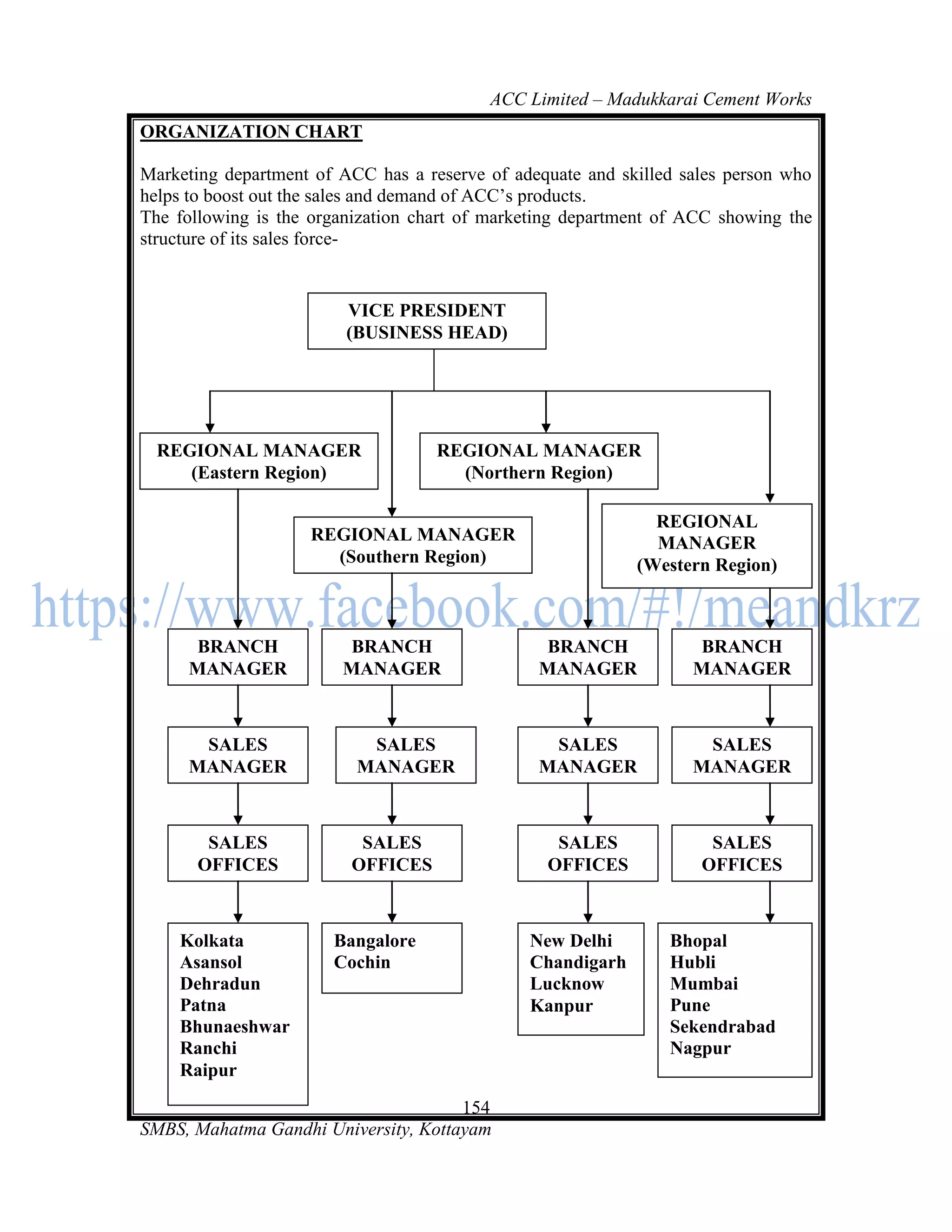

SALES UNIT HIERARCHY

The hierarchy of sales unit is illustrated below:

SALES HEAD

ACVERTISEMENT ADMIN

CSS AND BRANDING

FINANCE LOGISTICS

INCHARGE INCHARGE INCHARGE INCHARGE INCHAREGE

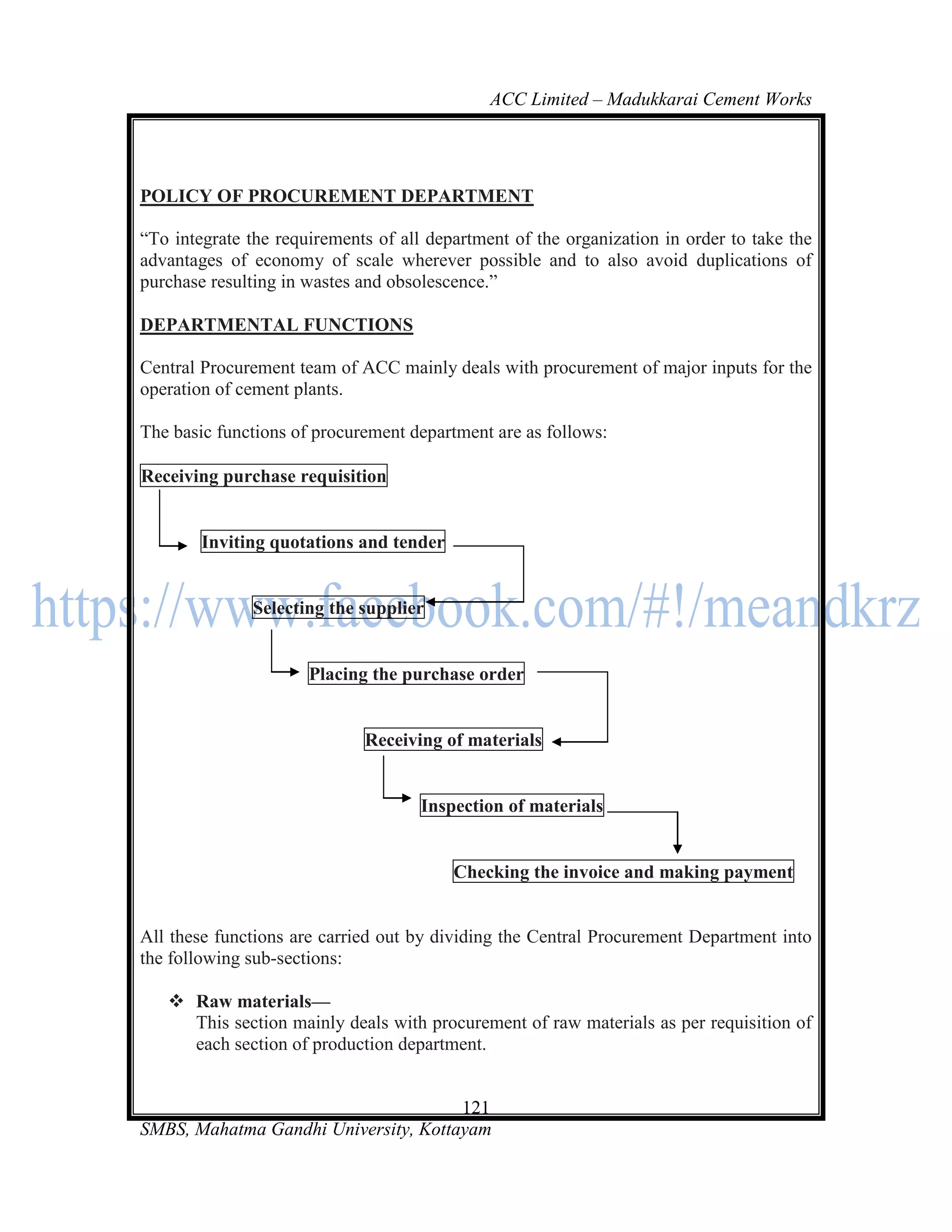

Thus as shown in the figure every sales unit has a sales head and all the sales/marketing

activities are performed under the sales head.

MARKETING MODEL

ACC sells the cement in the dealership mode and rarely in consignment mode. ACC

never sells products to the end user (Laye Buyer).

The marketing model is illustrated below:

ACC LIMITED

WHOLESAL E DEALER RETAIL DEALER

(SUB END CUSTOMER

DEALER)*

END CUSTOMER

* Three sub dealers [authorized dealers] – Premium Dealer

159

SMBS, Mahatma Gandhi University, Kottayam](https://image.slidesharecdn.com/acclimitedbychrisjose-120626042925-phpapp02/75/Acc-limitedbychris-jose-159-2048.jpg)