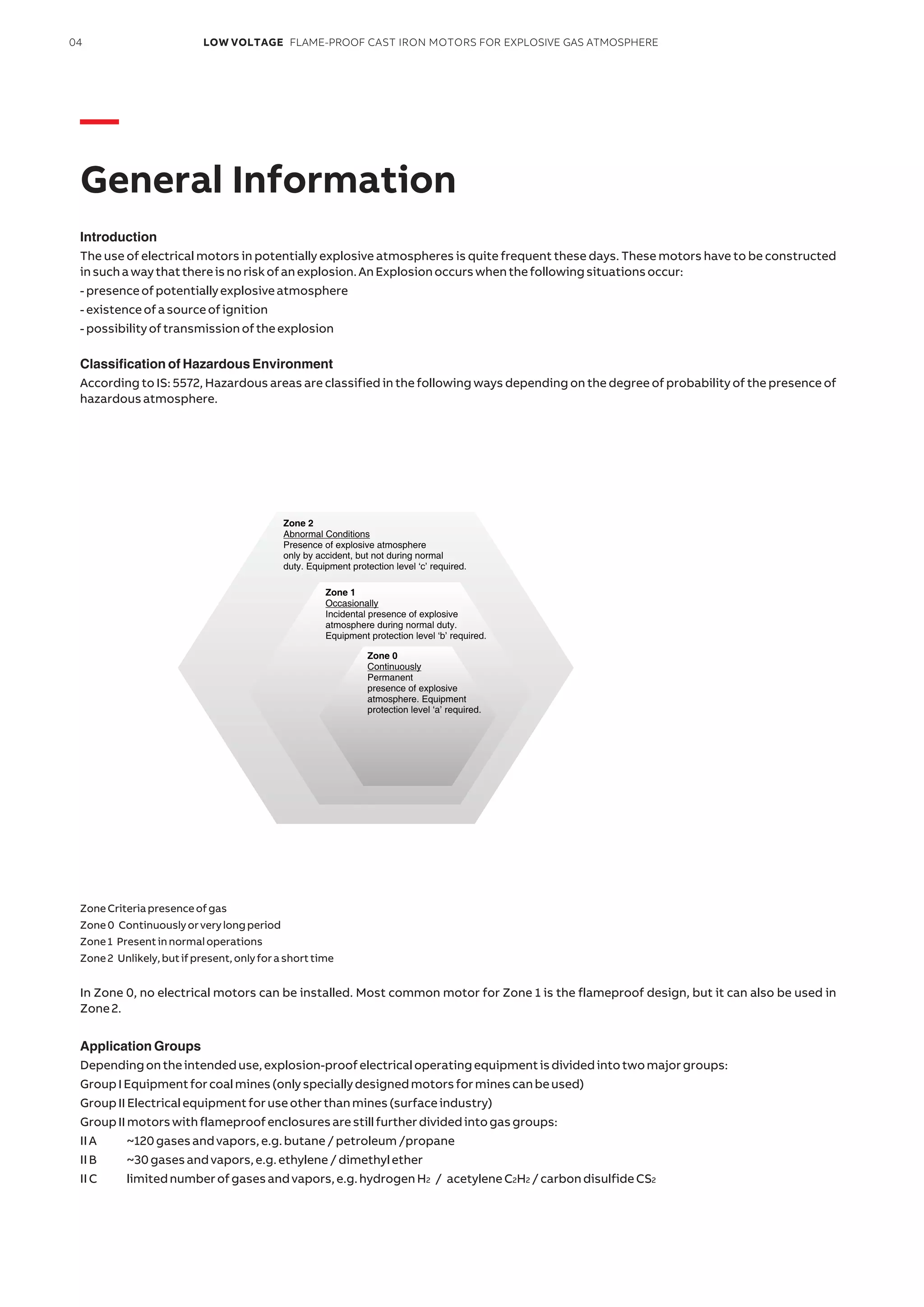

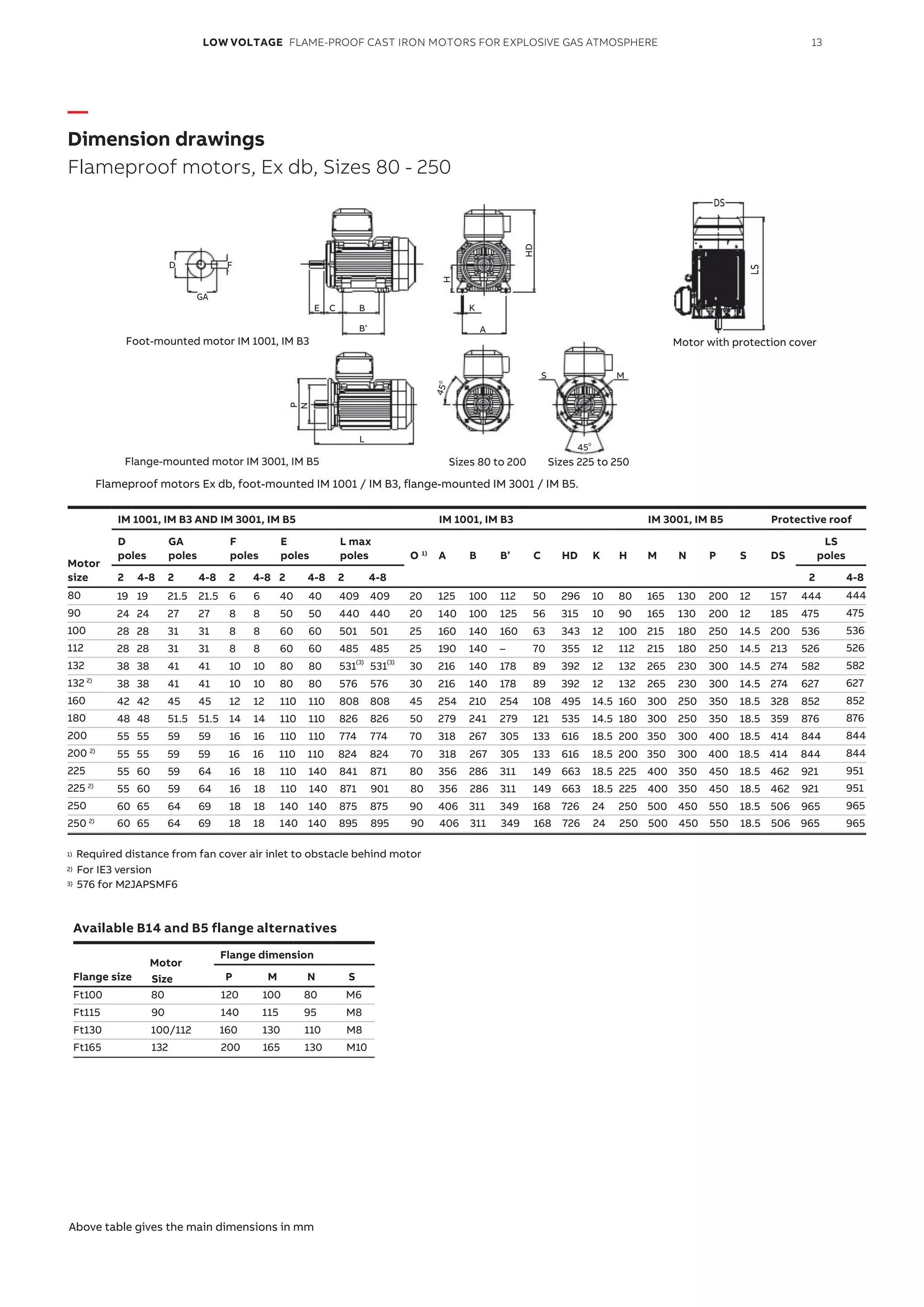

The document provides detailed information about low voltage flameproof motors designed for use in explosive gas atmospheres, highlighting their construction, classification, and operational safety requirements. It outlines specific technical data for various motor types, including their efficiency ratings, design standards, and appropriate applications for different hazardous zones. The document emphasizes the importance of proper design to prevent explosions and ensure safe operation in potentially dangerous environments.