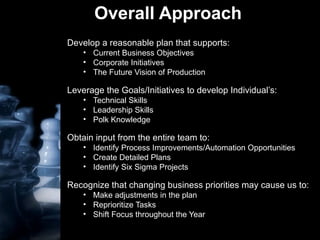

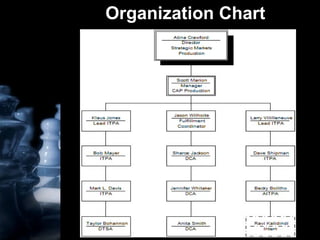

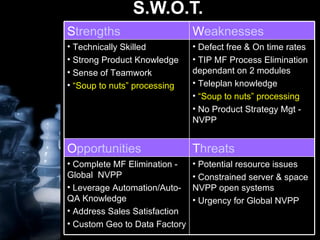

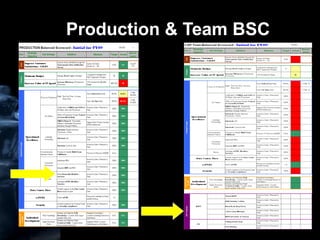

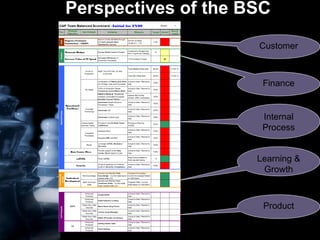

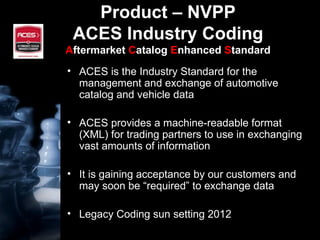

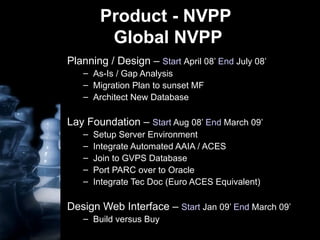

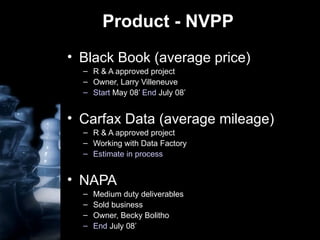

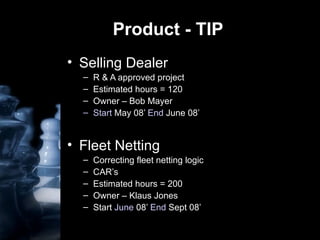

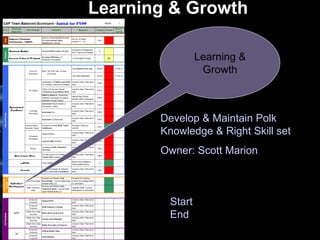

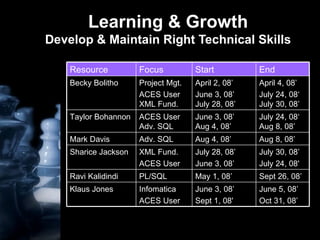

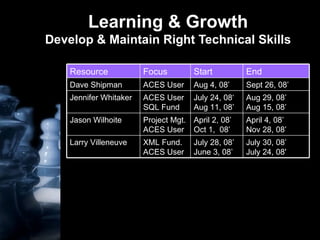

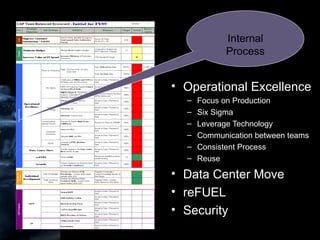

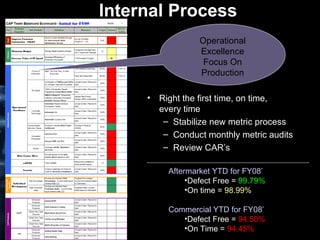

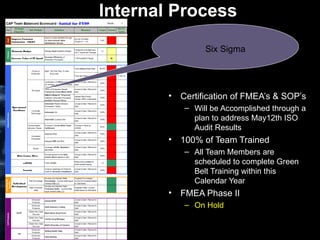

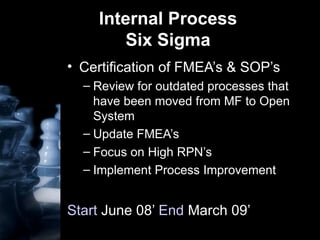

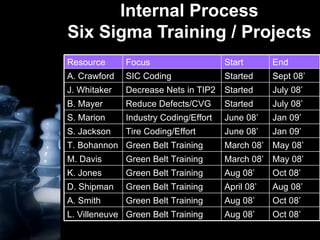

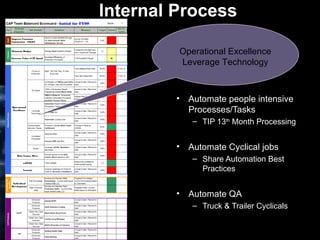

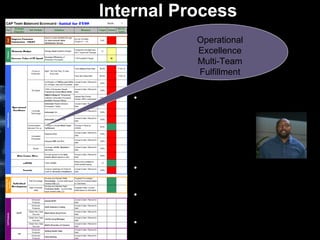

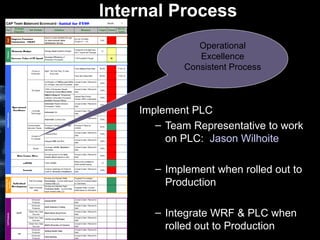

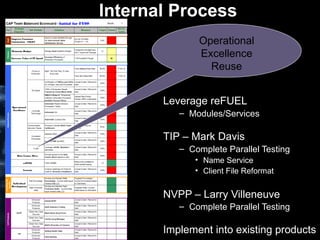

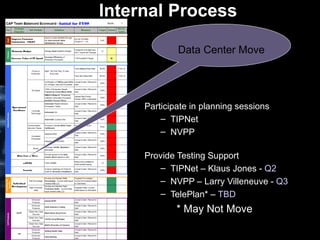

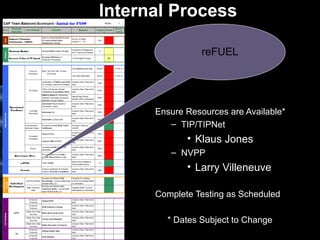

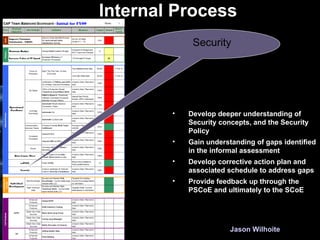

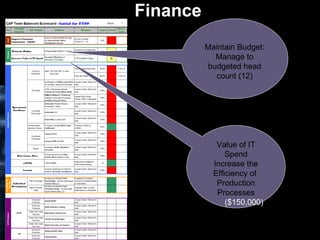

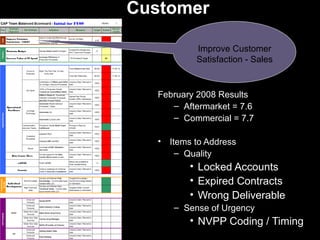

The document provides an agenda and overview of CAP Production's FY09 Balanced Scorecard and Strategic Plan. It discusses FY08 accomplishments, an overall approach and SWOT analysis, and outlines objectives and initiatives across key areas - Product, Learning & Growth, Internal Process, and Finance/Customer. Specific tasks and owners are assigned to initiatives focused on areas like NVPP, coding standards, process improvements, training, and metrics. Challenges around resources and priorities are also reviewed along with mitigation strategies.