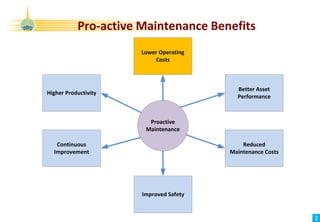

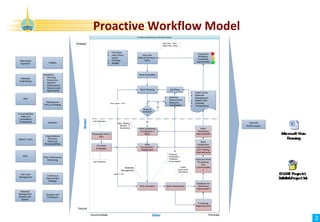

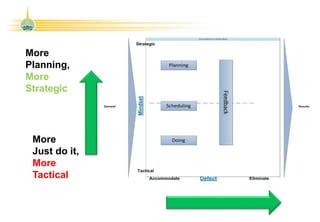

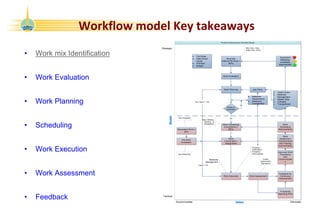

The document outlines a proactive maintenance workflow model designed to enhance productivity, reduce costs, and improve asset performance. Key components include work planning, scheduling, execution, and assessment, along with emphasis on continuous feedback and strategic management. Overall, it promotes a comprehensive approach to maintenance that includes risk assessments, resource coordination, and ongoing improvements.