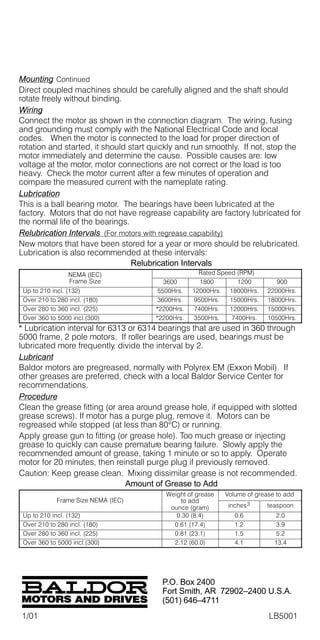

1) The document provides instructions for safely installing and maintaining AC motors, including handling, receiving, safety procedures, mounting, wiring, lubrication, and relubrication intervals.

2) Safety precautions that must be followed include using proper lifting equipment, inspecting for damage, grounding the motor, providing guards for moving parts, securing keys before starting, and only connecting to the proper voltage and frequency.

3) Motors should be mounted securely to a rigid foundation using shims if needed, and direct coupled machines must be carefully aligned with the shaft rotating freely.