The document discusses various methods for neutralizing industrial waste to ensure safe discharge into municipal sewage systems and compliance with regulatory standards. It outlines techniques such as mixing alkaline and acidic wastes, using limestone and lime slurries, and applying concentrated caustic soda or sulfuric acid. Additionally, the importance of equalization and proportioning in waste treatment is highlighted to maintain uniform effluent quality and minimize impacts on municipal systems.

![NEUTRALISATION

Carbon Dioxide Treatment:

i. Bottled CO2 is applied to wastewater in much the same way as compressed air is applied to

activated-sludge basins.

ii. It neutralizes alkaline wastes on the same principle as boiler-feed gases (i.e., it forms a weak

acid [carbonic acid] when dissolved in water) but with much less operating difficulty.

iii. Producing Carbon Dioxide in Alkaline Wastes Another way to produce carbon dioxide is to

burn gas underwater.

i. Submerged combustion on a continuous basis, using an evaporation vessel, a burner with flame jets

submerged below the waste surface in the vessel, a bustle in which air and natural gas were mixed to

form a combustible mixture, and other equipment to measure air, gas, and waste flows and the

weight of waste volatilized during each run

ASST. PROF. PRACHI DESSAI, DON BOSCO COLLEGE OF ENGINEERING 10](https://image.slidesharecdn.com/06-neutralisationequalisationproportioning-220509121937-deec58d7/85/06-Neutralisation-Equalisation-Proportioning-pptx-10-320.jpg)

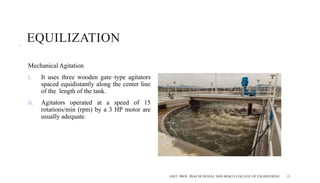

![EQUILIZATION

i. Equalization is a method of retaining waste in a basin so that the effluent discharged is

fairly uniform in its water quality characteristics

ii. pH, color, turbidity, alkalinity, biochemical oxygen demand [BOD]

iii. Air is sometimes injected into these basins to provide

a. better mixing

b. chemical oxidation of reduced compounds

c. some degree of biological oxidation

d. agitation to prevent suspended solids from settling.

This mixing may be brought about in the following ways:

a. proper distribution and baffling

b. Mechanical agitation

c. Aeration

d. combinations of all three.

ASST. PROF. PRACHI DESSAI, DON BOSCO COLLEGE OF ENGINEERING 13](https://image.slidesharecdn.com/06-neutralisationequalisationproportioning-220509121937-deec58d7/85/06-Neutralisation-Equalisation-Proportioning-pptx-13-320.jpg)