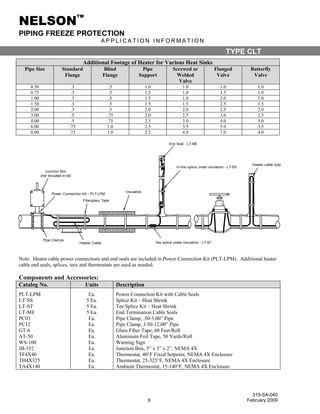

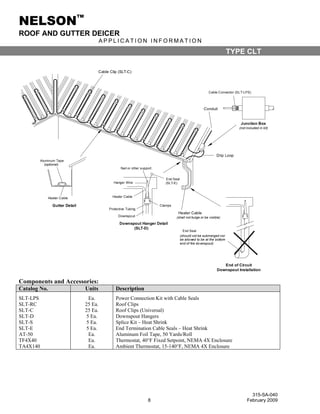

The document provides specifications and application information for Nelson Type CLT self-regulating heater cables. The cables consist of stranded copper conductors, a self-regulating conductive core, a thermoplastic elastomer jacket, and standard overjacket and metal braid. Tables are included that recommend cable wattages needed to maintain fluid temperatures in pipes of various sizes, insulation thicknesses, and ambient temperatures down to -40°F. The heaters are intended for freeze protection and temperature maintenance in pipelines and other fluid systems.