7bws10-13 repair manual cl3ws-06.pdf

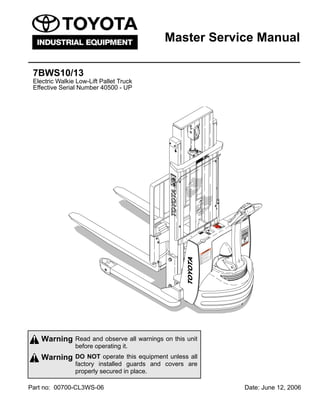

- 1. Master Service Manual Read and observe all warnings on this unit before operating it. DO NOT operate this equipment unless all factory installed guards and covers are properly secured in place. Warning Warning Part no: 00700-CL3WS-06 Date: June 12, 2006 7BWS10/13 Electric Walkie Low-Lift Pallet Truck Effective Serial Number 40500 - UP Front Cover

- 2. © Copyright 2006 by Toyota Industrial Equipment All rights reserved. No portion of this manual may be reproduced mechanically, electronically or by any other means, including photocopying, electronic retrieval or transfer, or recording without the written permission of the publisher. Toyota Industrial Equipment believes the information in this manual is accurate and current as of the publication date; such information is subject to change without notice. Toyota Industrial Equipment is not responsible for any errors that may appear in the manual.

- 3. Ordering Spare Parts F-code Section C-code Version no T-code 000 7BWS10/13 1 2006-06-12 Master Service Manual Ordering Spare Parts Supply the following information will assure prompt, efficient handling of the order: 1. Identify truck model and serial number. 2. Refer to Parts Book and locate page with the exploded diagram. 3. Find item number for the part required. Select the column for the actual truck model and serial number. 4. The following is an explanation of a serial number: 5. Note part number. 6. Call your local Toyota Dealer and state part number. 7. If the truck model, serial number, or article number cannot be found on the truck, call your local Toyota Dealer for assistance. Although some trucks appear to be similar, component parts may not be interchangeable. If an incorrect part is used, the truck may malfunction. 7BWS10 40500 Truck number Capacity 10-2000 lbs Model (7BWS) 13-2500 lbs CAUTION

- 4. 000 7BWS10/13 Version no T-code F-code Section C-code Ordering Spare Parts 2 2006-06-12 Master Service Manual This page is intentionally left blank.

- 5. Table of Contents 3 Master Service Manual 2006-06-12 Ordering Spare Parts .................................................................................... 1 Standard Codes ............................................................................................ 11 Warning Symbols ......................................................................................... 13 Warning Levels ..................................................................................................... 13 Prohibitory Symbols .................................................................................... 14 Ordinance Symbols .............................................................................................. 14 Safety ............................................................................................................. 15 General Safety ..................................................................................................... 15 Battery Safety ............................................................................................... 20 Static Discharge Precautions ...................................................................... 25 Welding Safety .............................................................................................. 27 Introduction, Service Manual ...................................................................... 29 Contents, Section M ..................................................................................... 31 Machine Information ............................................................................................. 31 General Product Information ....................................................................... 33 Truck Presentation ............................................................................................... 33 Truck Side Views .......................................................................................................... 33 Intended Truck Application ........................................................................................... 33 Prohibited Truck Application ......................................................................................... 34 Truck Data .................................................................................................................... 34 Dimensions ................................................................................................................... 35 Data Plate ..................................................................................................................... 36 Main Components ................................................................................................ 37 Inch (SAE) and Metric Fasteners ................................................................ 39 Introduction .......................................................................................................... 39 Nomenclature, Threads ........................................................................................ 40 Strength Identification ........................................................................................... 41 Truck Torque Specifications ................................................................................. 47 Conversion of Metric and English Units ............................................................... 48 Technical Service Data ................................................................................ 51 Contents, Section P ...................................................................................... 55 Planned Maintenance ........................................................................................... 55 Introduction, Maintenance ........................................................................... 57 Jacking Truck Off The Floor ................................................................................. 58 Table Of Contents

- 6. Table of Contents 4 Master Service Manual 2006-06-12 Elevate Rear of Truck ................................................................................................... 58 Elevate Either Side of Truck ......................................................................................... 59 Lubricants ............................................................................................................ 59 Standard ....................................................................................................................... 59 Service Schedule ......................................................................................... 61 Planned Maintenance Schedule .......................................................................... 61 Planned Maintenance Procedures ....................................................................... 65 General ......................................................................................................................... 65 Hardware ................................................................................................................. 65 Noise ....................................................................................................................... 65 Leaks ....................................................................................................................... 65 Cables and Connections ......................................................................................... 66 Grease Location Points ........................................................................................... 66 Services Performed Daily or Every 8 Operating Hours ................................................ 66 Chassis ................................................................................................................... 66 Brakes ..................................................................................................................... 66 Wheels/Tires ........................................................................................................... 66 Tiller Arm ................................................................................................................. 66 Functions/Operations .............................................................................................. 67 Battery ..................................................................................................................... 67 Battery Connector ................................................................................................... 67 Services Performed Every Six Months or 500 Operating Hours Under Moderate Usage or Three Months or 250 Hours Under Severe Usage ....................................... 68 Chassis ................................................................................................................... 68 Motors ..................................................................................................................... 68 Drive Unit ................................................................................................................ 68 Brake ....................................................................................................................... 68 Electrical Control System ........................................................................................ 69 Battery ..................................................................................................................... 69 Electrical Panel ....................................................................................................... 69 Hydraulic System .................................................................................................... 69 Mast ........................................................................................................................ 69 Lifting Devices ......................................................................................................... 69 Services Performed 12 Months or Every 1000 Operating Hours Under Moderate Usage and Six Months or Every 500 Operating Hours Under Severe Usage 70 Drive Unit ................................................................................................................ 70 Hydraulic System .................................................................................................... 70 Lubrication Chart ......................................................................................... 71 Oil and Grease Specifications .................................................................... 72 Lubricants ............................................................................................................ 72 Grease Location Points ........................................................................................ 72 Contents, Section S ..................................................................................... 73 Service Instructions .............................................................................................. 73 Stabilizer Support Arms .............................................................................. 75 Theory of Operation ............................................................................................. 76 Maintenance ........................................................................................................ 76

- 7. Table of Contents 5 Master Service Manual 2006-06-12 Support Arm Width Adjustment .................................................................................... 76 Inspection, Covers ....................................................................................... 81 Theory of Operation ............................................................................................. 82 Maintenance ......................................................................................................... 82 Troubleshooting .................................................................................................... 82 Repair and Rebuild ............................................................................................... 82 Decals ............................................................................................................ 83 Decal with Protective Sheet ................................................................................. 83 Decal without Protective Sheet ............................................................................ 83 Electric Motors .............................................................................................. 85 Theory of Operation ............................................................................................. 85 Maintenance ......................................................................................................... 85 Troubleshooting .................................................................................................... 86 Repair and Rebuild ............................................................................................... 87 Pump Motor .................................................................................................................. 87 Removal .................................................................................................................. 88 Installation ............................................................................................................... 89 Drive Motor ................................................................................................................... 90 Brush Inspection and Replacement ........................................................................ 90 Brush Inspection ..................................................................................................... 90 Brush Replacement ................................................................................................. 92 Motor Disassembly .................................................................................................. 93 Motor Assembly ...................................................................................................... 94 Transmission ................................................................................................ 99 Theory of Operation ............................................................................................ 101 Maintenance ........................................................................................................ 101 Fluid Changing ............................................................................................................ 101 Troubleshooting ................................................................................................... 102 Repair and Rebuild .............................................................................................. 104 Parking Brake System ................................................................................. 111 Theory of Operation ............................................................................................ 112 Maintenance ........................................................................................................ 114 Mechanical Brake Release .......................................................................................... 114 Brake Adjustment ........................................................................................................ 114 Troubleshooting ................................................................................................... 115 Repair and Rebuild .............................................................................................. 116 Drive Wheel .................................................................................................. 117 Theory of Operation ............................................................................................ 117 Maintenance ........................................................................................................ 118 Drive Wheel Nut Inspection ......................................................................................... 118 Troubleshooting ................................................................................................... 120 Repair and Rebuild .............................................................................................. 121 Load Wheels ................................................................................................ 125

- 8. Table of Contents 6 Master Service Manual 2006-06-12 Theory of Operation ............................................................................................ 126 Maintenance ....................................................................................................... 126 Troubleshooting .................................................................................................. 126 Repair and Rebuild ............................................................................................. 126 Tiller Arm Handle ........................................................................................ 129 Theory of Operation ............................................................................................ 131 Maintenance ....................................................................................................... 131 Inspection .................................................................................................................... 131 Troubleshooting .................................................................................................. 131 Repair and Rebuild ............................................................................................. 132 Tiller Arm Head ............................................................................................ 135 Theory of Operation ............................................................................................ 137 Maintenance ....................................................................................................... 137 Troubleshooting .................................................................................................. 137 Repair and Rebuild ............................................................................................. 137 Steering Bearing ......................................................................................... 139 Theory of Operation ............................................................................................ 140 Maintenance ....................................................................................................... 140 Troubleshooting .................................................................................................. 140 Repair and Rebuild ............................................................................................. 140 Electrical Functions .................................................................................... 141 Theory of Operation ............................................................................................ 142 Battery Plugged In With Keypad ................................................................................. 142 Battery Plugged In With Key Switch ............................................................................ 144 Main ON/OFF Switch/Keypad ON ............................................................................... 146 Travel, Low Speed ...................................................................................................... 148 Travel, High Speed ...................................................................................................... 150 Reverser ...................................................................................................................... 152 Lift ................................................................................................................................ 154 Lower ........................................................................................................................... 156 Maintenance ....................................................................................................... 159 Wiring .......................................................................................................................... 159 Definitions .............................................................................................................. 159 Shorts to Frame Test ............................................................................................. 160 Troubleshooting .................................................................................................. 163 Troubleshooting Flowchart .......................................................................................... 163 Main Harness Replacement ........................................................................................ 166 Operator Display and Programming ............................................................................ 170 Special Modes ........................................................................................................ 170 Service Display ...................................................................................................... 171 Digital Inputs/Outputs from Transistor Controller ................................................... 172 Transistor Controller System Mode ........................................................................ 173 Changing Driver Accessible Parameters (P) ............................................................... 174 Changing Service Parameters .................................................................................... 176 Parameter Description ........................................................................................... 179 Operating Parameter Programming ....................................................................... 183

- 9. Table of Contents 7 Master Service Manual 2006-06-12 Display Part Numbers (Pn) .................................................................................... 183 Error Codes (E) ........................................................................................................... 183 Error Code History ................................................................................................. 183 Truck Fault Codes .................................................................................................. 184 Troubleshooting Chart Index ....................................................................................... 194 Travel (Tractor-first / Forks-first) System ............................................................... 194 Wiring System ........................................................................................................ 194 Other Possible Troubleshooting Issues ................................................................. 194 Troubleshooting Charts ............................................................................................... 195 Battery .......................................................................................................... 199 Theory of Operation ............................................................................................ 199 Maintenance ........................................................................................................ 199 Inspection and Care .................................................................................................... 199 Exterior Cleaning ......................................................................................................... 200 Charging ...................................................................................................................... 200 Storage ........................................................................................................................ 201 History Record ............................................................................................................. 202 Troubleshooting ................................................................................................... 202 Repair and Rebuild .............................................................................................. 203 Swing Out Battery Pack .............................................................................. 205 Theory of Operation ............................................................................................ 210 Maintenance ........................................................................................................ 210 Electrical Testing ......................................................................................................... 210 Required Equipment .............................................................................................. 210 Instructions ............................................................................................................. 210 Troubleshooting ................................................................................................... 215 Repair and Rebuild .............................................................................................. 215 Battery Connector ....................................................................................... 217 Theory of Operation ............................................................................................ 217 Maintenance ........................................................................................................ 217 Inspection .................................................................................................................... 217 Troubleshooting ................................................................................................... 218 Repair and Rebuild .............................................................................................. 220 Switches ....................................................................................................... 221 Theory of Operation ............................................................................................ 222 Maintenance ........................................................................................................ 223 Troubleshooting ................................................................................................... 224 Repair and Rebuild .............................................................................................. 225 Main ON/OFF Switch ................................................................................................... 225 Arm Angle Switches .................................................................................................... 225 Key Switch (Optional) .................................................................................................. 227 Horn Switch ................................................................................................................. 227 Converting Keypad to Key Switch ............................................................................... 227 Fuses ............................................................................................................ 229 Theory of Operation ............................................................................................ 229 Maintenance ........................................................................................................ 229

- 10. Table of Contents 8 Master Service Manual 2006-06-12 Wiring Harness ............................................................................................................ 230 Power Cables .............................................................................................................. 231 Master Control Relay ................................................................................................... 232 Troubleshooting .................................................................................................. 233 Repair and Rebuild ............................................................................................. 233 Contactor Panel ........................................................................................... 235 Theory of Operation ............................................................................................ 237 Maintenance ....................................................................................................... 237 Troubleshooting .................................................................................................. 237 Resistance Testing ...................................................................................................... 237 Repair and Rebuild ............................................................................................. 238 Transistor Controller .................................................................................. 239 Theory of Operation ............................................................................................ 239 Basics Of Circuit Operation ......................................................................................... 239 Interface ...................................................................................................................... 240 Control Features .......................................................................................................... 241 Motor Circuit ................................................................................................................ 241 Control Circuit .............................................................................................................. 242 Definitions .................................................................................................................... 243 Maintenance ....................................................................................................... 244 Safety .......................................................................................................................... 244 Cleaning ...................................................................................................................... 244 Troubleshooting .................................................................................................. 245 Diagnostics and Troubleshooting ................................................................................ 245 Fault Codes ................................................................................................................. 245 Repair and Rebuild ............................................................................................. 247 Electronic Tiller Arm Card (ETAC) ............................................................. 249 Theory of Operation ............................................................................................ 250 Lift Cutout. ................................................................................................................... 251 Maintenance ....................................................................................................... 251 Troubleshooting .................................................................................................. 251 Repair and Rebuild ............................................................................................. 251 Hydraulic System ........................................................................................ 253 Theory of Operation ............................................................................................ 253 Lift ................................................................................................................................ 254 Lower ........................................................................................................................... 255 Relief Pressure ............................................................................................................ 256 Maintenance ....................................................................................................... 257 Changing Hydraulic System Fluid ............................................................................... 257 Hydraulic Pump Pressure Relief Valve ....................................................................... 259 Troubleshooting .................................................................................................. 259 Troubleshooting Chart Index ....................................................................................... 260 Troubleshooting Charts ............................................................................................... 260 Repair and Rebuild ............................................................................................. 263 Hydraulic Unit .............................................................................................................. 265 Reservoir ..................................................................................................................... 266

- 11. Table of Contents 9 Master Service Manual 2006-06-12 Filter Screen and Inlet Tube ........................................................................................ 267 Lift Pump ..................................................................................................................... 268 Lift Cylinder .................................................................................................. 269 Theory of Operation ............................................................................................ 270 Maintenance ........................................................................................................ 270 Inspection .................................................................................................................... 270 Troubleshooting ................................................................................................... 270 Repair and Rebuild .............................................................................................. 271 Mast .............................................................................................................. 275 Theory of Operation ............................................................................................ 275 Maintenance ........................................................................................................ 275 Visual Inspection ......................................................................................................... 275 Lift Chain Inspection .................................................................................................... 275 Lift Chain Lubrication ................................................................................................... 280 Lift Chain Adjustment .................................................................................................. 281 Mast Guides/Dampers Adjustment .............................................................................. 281 Troubleshooting ................................................................................................... 282 Repair and Rebuild .............................................................................................. 283 Forks ............................................................................................................. 297 Theory of Operation ............................................................................................ 298 Maintenance ........................................................................................................ 298 Inspection .................................................................................................................... 298 Troubleshooting ................................................................................................... 298 Repair and Rebuild .............................................................................................. 299 Appendix ...................................................................................................... 301

- 12. Table of Contents 10 Master Service Manual 2006-06-12 This page is intentionally left blank.

- 13. Standard Codes F-code Section C-code Version no T-code 000 7BWS10/13 11 2006-06-12 Master Service Manual Standard Codes B-Code = Business area F-Code = Product family T-Code = Product type C-Code = Component function Worksheet standard W-Code = Working code R-Code = Reason code SO-Code = Assortment F-Code List T-Code List No. Model 7BWS10/13 C-Code List No Function Group C-Code 0 Chassis / Frame 0000 1 Motors 1000 2 Drive Gear / Transmission 2000 3 Brake / Wheel System 3000 4 Steering System 4000 5 Electrical System 5000 6 Hydraulic / Pneumatic System 6000 7 Operating Function-lifting Mast / Cylinders 7000 8 Peripheral / Installation Equipment 8000 9 Optionals / Attachments 9000 10 Tools 10000

- 14. 000 7BWS10/13 Version no T-code F-code Section C-code Standard Codes 12 2006-06-12 Master Service Manual This page is intentionally left blank.

- 15. Warning Symbols F-code Section C-code Version no T-code 001 13 Master Service Manual 2006-06-12 Warning Symbols Always follow the warnings given in this Service Manual and on the truck to avoid accidents from occurring. 1. Warning Levels Warning levels Warning text is given in four levels and provide information on the risks, describe the consequences, and instruct how to avoid accidents. DANGER Warns that an accident will occur if the instructions are not followed. The consequences are serious personal injury or possibly death, and/or extremely large material damage. WARNING Warns that an accident can occur if the instructions are not followed. The consequences are serious personal injury or possibly death, and/or large material damage. CAUTION Warns that an accident can occur if the instructions are not followed. The consequences are personal injury and/or material damage. NOTE! Marks the risk of a accident or breakdown if the instructions are not followed.

- 16. 001 Version no T-code F-code Section C-code Prohibitory Symbols 14 Master Service Manual 2006-06-12 Prohibitory Symbols NO SMOKING If smoking occurs in situations where a restriction against smoking is stated, a serious accident can occur. OPEN FLAMES PROHIBITED If open flames are used in situations where open flames are prohibited, a serious accident can occur. GENERAL PROHIBITION If the prohibition is ignored, a serious accident can occur. 1. Ordinance Symbols SAFETY SHOES When the directive for safety shoes is given, safety shoes shall always be worn to avoid personal injury. PROTECTIVE GLASSES When the directive for protective glasses is given, protective glasses shall always be worn to avoid personal injury.

- 17. Safety F-code Section C-code Version no T-code 001 15 Master Service Manual 2006-06-12 Safety 1. General Safety Do NOT operate or work on this truck unless trained, qualified, and authorized to do so and have read the Operator’s Manual. Know the truck controls and what they do. Do NOT operate truck if it needs repair or if it is in any way unsafe.

- 18. 001 Version no T-code F-code Section C-code Safety 16 Master Service Manual 2006-06-12 Operate truck only from the position of the operator. Before working on this truck always press the red OFF (O) key on the keypad and disconnect truck battery connector (unless this manual states otherwise). Do NOT wear watches, rings, or jewelry when working on this truck.

- 19. Safety F-code Section C-code Version no T-code 001 17 Master Service Manual 2006-06-12 Follow the scheduled lubrication, maintenance, and inspection steps. Follow exactly the safety and repair instructions in this manual. Do NOT take “shortcuts”. Do NOT Use an open flame near the truck. Do NOT use gasoline or other flammable liquids for cleaning parts.

- 20. 001 Version no T-code F-code Section C-code Safety 18 Master Service Manual 2006-06-12 Clean up any hydraulic fluid, oil, or grease that has leaked or spilled on the floor. Always operate and park truck indoors. Do not park truck in a cold storage area overnight. Do NOT wash truck with a hose.

- 21. Safety F-code Section C-code Version no T-code 001 19 Master Service Manual 2006-06-12 Do NOT add to or modify truck without written approval from Toyota

- 22. 001 Version no T-code F-code Section C-code Battery Safety 20 Master Service Manual 2006-06-12 Battery Safety Read, understand and follow procedures, recommendations and specifications available by the battery and battery charger supplier. As a battery is being charged, an explosive gas mixture forms within and around each cell. If the area is not properly ventilated, this explosive gas can remain in or around the battery for several hours after charging. Be sure there are no open flames or sparks in the charging area. An open flame or spark can ignite this gas, resulting in serious damage or injury. Battery electrolyte is a solution of sulfuric acid and water. Battery acid causes burns. Should any electrolyte come in contact with clothing or skin, flush the area immediately with cold water. Should the solution get on your face or in the eyes, flush the area with cold water and receive medical attention immediately. WARNING WARNING

- 23. Battery Safety F-code Section C-code Version no T-code 001 21 Master Service Manual 2006-06-12 Wear personal protective equipment to protect eyes, face, and skin when checking, handling, or filling batteries. This equipment includes goggles or face shield, rubber gloves (with or without arm shields) and a rubber apron. Make sure a shower and eyewash station are nearby in case there is an accident. A battery gives off explosive gases. Never smoke, use an open flame, or use anything that gives off sparks near a battery.

- 24. 001 Version no T-code F-code Section C-code Battery Safety 22 Master Service Manual 2006-06-12 Keep the charger area well-ventilated to avoid hydrogen gas concentration. Press the red OFF (O) key on the keypad before disconnecting the battery from the truck at the battery connector. Do NOT break live circuits at the battery terminals. A spark often occurs at the point where a live circuit is broken. Do NOT lay tools or metal objects on top of battery. A short circuit or explosion could result. Keep batteries clean. Corrosion causes shorts and possibly sparks to the frame.

- 25. Battery Safety F-code Section C-code Version no T-code 001 23 Master Service Manual 2006-06-12 Keep plugs, terminals, cables, and receptacles in good condition to avoid shorts and sparks. Keep filler plugs firmly in place at all times except when the electrolyte level is checked, when water is added to the cells or when the specific gravity is checked. Make sure vent holes in filler plugs are open to allow gas to escape from the cells. Do NOT allow cleaning solution, dirt, or any foreign matter to enter the cell. Filler Plugs Cable Filler Plug Vent Hole

- 26. 001 Version no T-code F-code Section C-code Battery Safety 24 Master Service Manual 2006-06-12 Make sure to install the correct size and weight battery. A smaller or lighter weight battery could seriously affect truck stability. See the truck specification (data) plate for more information. Never plug a battery charger into the truck battery connector. Plug battery charger ONLY into battery connector from battery. Follow the charging procedures available by the supplier on the “Battery” and “Battery Charger”.

- 27. Static Discharge Precautions F-code Section C-code Version no T-code 001 25 Master Service Manual 2006-06-12 Static Discharge Precautions Electronic circuit board and devices used on the truck can be damaged by the discharge of static electricity, called electrostatic discharge. Static charges can accumulate from normal operation of the truck as well as movement or contact between non- conductive materials such as plastic bags, synthetic clothing, synthetic soles on shoes, styrofoam coffee cups, etc. Accumulated static can be discharged through human skin to a circuit board or component by touching the parts. Static discharge is also possible through the air when a charged object is placed close to another surface at a different electrical potential. Static discharge can occur without seeing or feeling it. Whenever working on or near static-sensitive electronics, always use static discharge precautions. 1. Static-sensitive items are to remain in their protective containers except when actually in use at the static-free station. 2. Before removing the item(s) from their protective container, the operator should place the container on the conductive grounded bench top. Make sure the wrist strap fits snugly around the wrist and is properly plugged in/attached to ground receptacle or the truck. The operator should then touch hands to the conductive bench top, workstation, or truck. 3. All operations should be performed with the items in contact with the truck or grounded bench top. 4. Do not allow conductive magazine (static-sensitive items) to touch hard-grounded test gear or bench top. 5. Ordinary plastic solder-suckers and other plastic assembly aids should not be used. 6. In cases where it is impossible or impractical to ground the operator with a wrist strap, a conductive shoe strap can be used along with conductive tile/ mats.

- 28. 001 Version no T-code F-code Section C-code Static Discharge Precautions 26 Master Service Manual 2006-06-12 7. When the operator moves from any other place to the static-free station, the start-up procedure should be the same as the preparation for working at a static-free workstation. 8. “Plastic snow” polystyrene foam, peanuts, or other high-dielectric materials should never come in contact with or be used around electrostatic sensitive items, unless they have been treated with an antistatic compound. Such treatment is often indicated by a pink color on the foam material. 9. Static-sensitive items should not be transported or stored in trays, tote boxes, vials, or similar containers made of untreated plastic material unless items are protectively packaged in conductive material.

- 29. Welding Safety F-code Section C-code Version no T-code 001 27 Master Service Manual 2006-06-12 Welding Safety Before working on the truck, make sure of the following: • Fire protection equipment is nearby. • Know where the nearest eyewash station is located. Flame cutting or welding on painted surfaces may produce potentially harmful fumes, smoke and vapors. Prior to performing flame cutting or welding operations, it is recommended that the coating be removed in the vicinity where the operation(s) will be performed. Coating removal may be by mechanical methods, chemical methods or a combination of methods. Flame cutting and/ or welding operations should be carried out in well ventilated areas using local exhaust if necessary. WARNING WARNING

- 30. 001 Version no T-code F-code Section C-code Welding Safety 28 Master Service Manual 2006-06-12 • Check for shorts to frame. If any shorts are detected, remove before proceeding with the welding operation. • Clean the area to be welded. • Protect all truck components from heat, weld spatter and debris. • Attach the ground cable as close to the weld area as possible. • Disconnect all electrical cards before any type of electric resistance welding is done. • Only trained, qualified, and authorized personnel should weld on the truck. • Do not perform any welding operations near the electrical components. • If welding must be done, disconnect and remove the battery from the truck. • When welding is completed, perform all ground tests and electrical inspections before the truck is operated. Disconnect battery before attempting to inspect, service or repair truck. Discharge residual charge in the transistor controller by connecting a load across the transistor controllers B+ and B- terminals (such as a contactor coil or by pressing the horn button). CAUTION

- 31. Introduction, Service Manual M F-code Section C-code Version no T-code 000 7BWS10/13 29 Master Service Manual 2006-06-12 Introduction, Service Manual The information in this service manual covers model 7BWS10/13. Federal and State laws require that operators be completely trained in the safe operation of lift trucks in accordance with OHSA regulation 1910.178. An operator’s manual is sent with every Toyota truck when it is manufactured. If the operator’s manual is missing from the truck, a new manual may be obtained by contacting: Toyota Industrial Equipment www.toyotaforklift.com The information contained in this service manual is intended as a guide to help trained, qualified, and authorized technicians safely service the truck. The service manual is divided into four separate sections which cover needed information for servicing the truck types. The main subject for each of these sections is described below. SECTION SUBJECT M MACHINE INFORMATION P PLANNED MAINTENANCE S SERVICE INSTRUCTIONS O OPTIONS

- 32. M 000 7BWS10/13 Version no T-code F-code Section C-code Introduction, Service Manual 30 2006-06-12 Master Service Manual This page is intentionally left blank.

- 33. Contents, Section M M F-code Section C-code Version no T-code 000 31 Master Service Manual 2006-06-12 Contents, Section M 1. Machine Information M1.0 GENERAL PRODUCT INFORMATION M2.0 TECHNICAL SERVICE DATA

- 34. M 000 Version no T-code F-code Section C-code Contents, Section M 32 2006-06-12 Master Service Manual This page is intentionally left blank.

- 35. General Product Information M1.0 F-code Section C-code Version no T-code 000 7BWS10/13 33 Master Service Manual 2006-06-12 General Product Information 1. Truck Presentation The 7BWS10/13 are battery powered adjustable baseleg stacker trucks. These trucks are intended solely to be operated indoors carrying pallets or similar load carriers. The trucks are equipped with a tiller arm with all the controls for operating within easy access. The trucks lifting capacities can be found on the truck’s data plate. The 7BWS10/13 trucks are equipped with a 24 volt electrical system. Speed is regulated by means of a transistor controller to provide infinite control of acceleration and speed while driving. The forks are raised by means of a hydraulic unit. The control of the lift/lower is activated by rotating the control on the tiller arm handle head. 1.1. Truck Side Views The terms right-hand and left-hand used indicate the right and left side of the truck as viewed from the operator’s line of sight for proper operation of the truck. Use this view when ordering parts to assure proper selection of parts. 1.2. Intended Truck Application The trucks are solely designed and manufactured to handle goods. The trucks should be fitted with the appropriate accessories relevant to the application. Right Side Left Side Tractor-first Forks-first

- 36. M1.0 000 7BWS10/13 Version no T-code F-code Section C-code General Product Information 34 2006-06-12 Master Service Manual 1.3. Prohibited Truck Application The trucks are designed for handling goods indoors. It is not permitted to use the trucks for other purposes including the following: • As a towing tractor for trailers. • To tow other trucks. • To transport/lift passengers. • To drive on gravel or grass. 1.4. Truck Data The following table provides information regarding technical data which is of value with daily use of the trucks. Lifting capacity and weight can be found on the truck’s data plate (see page 36). Metric dimensions and capacities are shown in parenthesis and have been rounded for convenience. Truck Data 7BWS10/13 Traveling speed mph (kph) Without Load 0 - 3.6 mph (0 - 5.7) Loaded 0 - 3.4 mph (0 - 5.4) Service weight, lb (kg) Without battery 1610 - 1875 (730 - 850) With battery 1910 - 2425 (866 - 1100)

- 37. General Product Information M1.0 F-code Section C-code Version no T-code 000 7BWS10/13 35 Master Service Manual 2006-06-12 1.5. Dimensions The following diagram shows external dimensions for the 7BWS10/13 truck in its standard design. R E H P D B C A S V U J L M N Q W F T X G K T A = 58.9 inch (1496 mm) J = 48.6 inch (1234 mm) S = 3.9 inch (99 mm) B = 47.0 inch (1194 mm) K = 24.2 inch (615 mm) T = 10/31.5 inch (254/800 mm) C = 21.0 inch (553 mm) L = 10.0 inch (254 mm) U = 6 inch (152 mm) [Fork Free Lift Height] D = 7.2 inch (183 mm) M = 27.3 X 7.8 inch (693 X 198 mm) U = 128 inch (3251 mm) [Max Fork Height] E = 33.2 inch (843 mm) N = 1.6 inch (41 mm) V = 2.0 inch (51 mm) F = 54.2 inch (1377 mm) P = 4 inch (100 mm) W = 84 inch (2134 mm) G = 28.0 inch (711 mm) Q = 32 to 51 inch (813 to 1295 mm) X = 168 inch (4267 mm) H = 32.8 inch (833 mm) R = 40 to 59 inch (1016 to 1499 mm) G P Q W R J X H U L B V S C A D N K 8° 38° 87° 35° 6° E M F 41°

- 38. M1.0 000 7BWS10/13 Version no T-code F-code Section C-code General Product Information 36 2006-06-12 Master Service Manual Battery packs available from the factory. 1.6. Data Plate The illustration shows the data plate used on this truck. Battery Pack Dimension Specifications 24 Volt Battery Pack Amp Hour Length Width Height Weight Swing-out Upper Trays with 15 amp charger 152 26.5 inch (675 mm) 7.5 inch (192 mm) 26.45 inch (672 mm) 330 lbs (150 kg) GNB PalletPro™ with 25 amp charger 195 26.5 inch (675 mm) 7.5 inch (192 mm) 26.25 inch (665 mm) 375 lbs (171 kg) Legend 1 Truck model number 7 Minimum battery weight 2 Truck serial number 8 Maximum battery weight 3 Truck type 9 Battery maximum AMP hours 4 Truck weight (less battery) 10 Hour Rate 5 Attachment 11 Truck voltage DC 6 Truck lifting capacity 12 Battery type UL class 1 2 3 4 5 6 7 8 9 10 11 12 C A B

- 39. General Product Information M1.0 F-code Section C-code Version no T-code 000 7BWS10/13 37 Master Service Manual 2006-06-12 2. Main Components 1. Tiller Arm: The truck is to be controlled by the operator with 180 degree steering angle. The brake is applied in the upper and lower position of the tiller arm head. 2. Hydraulic unit: Pump motor, pump, electric valve and oil tank reservoir integrated in a compact unit. 3. Hydraulic lowering valve: For controlling lifting and lowering functions with hydraulic lowering valve. 4. Battery: 24 volt with different capacities and weights. 5. Drive unit with brake: Drive unit with a spring-loaded electromagnetic brake, drive motor, drive wheel, and transmission assembly. The steering bearing is located at the top of the drive unit. 6. Steering pivot point. 7. Data plate: See data plate on page 36. 8. Operator Display: Display includes hourmeter, error codes, parameters, hardware and software part numbers. 9. Electrical panel: 24 volt electrical system. Truck speed is regulated by means of a transistor controller. 10.Fuse: 10A, Fuse Keypad and ETAC (supplied with main harness) 10A, Fuse Main ON/OFF (supplied with main harness) 130A, Fuse (one for drive motor and one for pump motor) 11.Load wheel: The load wheels have seals on the outside of the bearings to protect them in wet environments. 12.Keypad: Enter PIN-key code in the keypad and press green ON (I) key on the keypad starts truck. Press red OFF (O) on the keypad to shut off electrical power to the control system. Up to 10 drivers can be assigned their own individual PIN-key code for access to the truck. 13.Main ON/OFF Switch: The main ON/OFF switch will cut off all electrical power to the control functions on the truck when pressed.

- 40. M1.0 000 7BWS10/13 Version no T-code F-code Section C-code General Product Information 38 2006-06-12 Master Service Manual 14.Travel speed / direction selection: To select direction, rotate thumb controls in the direction of travel. The further you rotate in that direction the faster the travel. 15.Fork lower switch: Forks will lower when switch is pressed or until mast reaches the top. Then, if dead headed, the relief valve relieves the pressure. 16.Fork raise switch: Forks raise when switch is pressed or until mast reaches the top. Then, if dead headed, the relief valve relieves the pressure. 17.Horn switch: Activates horn to warn others of your position. Horn button is also used to cycle through special truck mode displays (see page 170). 18.Battery Connector: Disconnects off all electrical power to the truck. 19.Mast Guard. 20.Baselegs: Adjustable in width from 32 to 51 inch (813 to 1300 mm). 2, 3 5 8 9, 10 7 12 11 4 6 13 1 14 15 16 17 18 19 20 1 2 3 4 5 6 7 8 9 O 0 I

- 41. Inch (SAE) and Metric Fasteners M1.1 F-code Section C-code Version no T-code 000 7BWS10/13 39 Master Service Manual 2006-06-12 Inch (SAE) and Metric Fasteners 1. Introduction Threaded fasteners such as bolts, nuts, cap screws, and studs are made to specifications that describe mechanical strength and hardness of fastener. A fastener used in a design application is selected in accordance with its specifications. Parts used on this truck are purchased from many countries. Many fasteners are similar but cannot be used as direct replacements. Service technicians must use replacement fasteners that have the same specifications. Fasteners made to each specification have identification marks for that specification. This specification is commonly called “grade” for SAE standards and “property” for metric standards. This section describes identification of some common fasteners. The metric system used is described as SI (International System of Units, also called SI in all languages). The SI system of measurement is described in ISO Standard 1000, 1973. 5 9 10 5 9 10

- 42. M1.1 000 7BWS10/13 Version no T-code F-code Section C-code Inch (SAE) and Metric Fasteners 40 2006-06-12 Master Service Manual 2. Nomenclature, Threads The thread design is specified by a series of numbers and letters for inch and metric fasteners (see figure below). The diameter of shank of fastener is shown first in the series, e.g. M12=12 mm, M20=20 mm (1/2=1/2 inch, 3/4=3/4 inch). The number of threads per inch is normally not shown for inch nomenclature and only UNC (Unified National Coarse) or UNF (Unified National Fine) is shown. This number of threads per inch is not shown because a UNC or UNF fastener has a standard number of threads per inch for a specific diameter. The length of a shank is often indicated as part of the description of a fastener. This length is shown in inches for inch fasteners and in millimeters for metric fasteners. A cap screw will have the following description: Inch Metric 1/2 x 13 UNC x 1-1/2 A B C D M12 x 1.75 x 50 A B C A =Shank diameter B =Number of threads per unit of length C =Type of thread D =Shank length A =Thread size B =Pitch C =Length

- 43. Inch (SAE) and Metric Fasteners M1.1 F-code Section C-code Version no T-code 000 7BWS10/13 41 Master Service Manual 2006-06-12 3. Strength Identification The most common property classes for metric fasteners are 8.8 and 10.9. The property class is marked with a number on the head of the cap screw or on a nut. Property classes less then 8.8 are often not marked. Grades for inch bolts go from 2 to 8. Grade 2 fasteners normally do not have marks. The following tables show marks that identify grades and property classes for different fasteners. When fasteners must be replaced new fasteners must be of same strength or greater than original fasteners. The new fasteners must also be the correct size. NOTE! Identification marks are according to bolt strength. The higher the number, or increase in number of marks, indicates increased bolt strength. WARNING

- 44. M1.1 000 7BWS10/13 Version no T-code F-code Section C-code Inch (SAE) and Metric Fasteners 42 2006-06-12 Master Service Manual Table 1. Bolt and Screw Designations Types of Fasteners Inch Fasteners Strength Levels: SAE Grades Metric Fasteners Strength Levels: Property Classes * Markings Not Required Markings Hex Head Bolts & Cap Screws Hex Head Flange Screws Same As Above 12 Point Flange Screws Markings Not Required Hex Socket Head Cap Screws Sems for size M5 and Larger 2 5 7 8 5 8 5 8 5.1 4.8* 9.8 8.8 12.9 4.6* 4.8* 5.8* 8.8 9.8 10.9 12.9 4.6 4.8 5.8 8.8 9.8 10.9 12.9 8.8 12.9 4.8 9.8 5.2

- 45. Inch (SAE) and Metric Fasteners M1.1 F-code Section C-code Version no T-code 000 7BWS10/13 43 Master Service Manual 2006-06-12 Table 2. Stud and Nut Designations Types of Fasteners Inch Fasteners Strength Levels: SAE Grades * Markings Not Required Metric Fasteners Strength Levels: Property Classes * Markings Not Required 5* Studs 5.2* 8* 8.1 Markings Not Required Markings Not Required Hex Nuts Hex Slotted Nuts Hex Flange Nuts 2 5 8 or or 5 8 9 10 12 5 8 9 10 12 5 8 9 10 12 5 8 9 10 12 5 8 9 10 12 5 5 8 8 9 9 12 12 10 10 or 4.6* 4.8* 5.8* 8.8 9.8 10.9 12.9 Optional Geometric Symbols for Size M5 through M11. Markings for size M5 and Larger 4.6 4.8 5.8 8.8 9.8 12.9 10.9

- 46. M1.1 000 7BWS10/13 Version no T-code F-code Section C-code Inch (SAE) and Metric Fasteners 44 2006-06-12 Master Service Manual Table 3. Torque Nut Designations Types of Fasteners Inch Fasteners Strength Levels: SAE Grades Metric Fasteners Strength Levels: Property Classes All Metal Prevailing Torque Nuts or or or All Metal Prevailing Torque Flange Nuts B A C B C 5 9 10 9 10 F G 5 9 10 9 10

- 47. Inch (SAE) and Metric Fasteners M1.1 F-code Section C-code Version no T-code 000 7BWS10/13 45 Master Service Manual 2006-06-12 Table 4. Torque Nut with Nylon Insert Designations Types of Fasteners Inch Fasteners Strength Levels: SAE Grades Metric Fasteners Strength Levels: Property Classes Markings Not Required Markings Not Required Nylon Insert Pre- vailing Torque Nuts Nylon Insert Pre- vailing Torque Flange Nuts or 9 10 9 10 5 9 10 5 9 10 or or or

- 48. M1.1 000 7BWS10/13 Version no T-code F-code Section C-code Inch (SAE) and Metric Fasteners 46 2006-06-12 Master Service Manual Table 5. Fastener Torque Values * Property class 8.8, Protective Treatment CMHC Specification “H” (zinc phosphate), applies also to internally threaded fasteners made of property class 8 material. ** Property class 10.9, Protective Treatment CMHC Specification “H” (zinc phosphate), applies also to internally threaded fasteners made of property class 10 material. *** Property class 12.9, Protective Treatment CMHC Specification “H” (zinc phosphate), applies also to internally threaded fasteners of property class 12 material. Size and Pitch Property, Class 8.8* Property, Class 10.9** Property, Class 12.9*** N•m in-lbs N•m in-lbs N•m in-lbs M5 x 0.8 M6 x 1 M8 x 1.25 5-6 8-10 20-25 44-53 71-88 177-221 7-8 12-14 30-35 62-71 106-124 265-309 8-10 14-16 ------------ 71-88 124-142 ------------ Size and Pitch N•m ft-lbs N•m ft-lbs N•m ft-lbs M8 x 1.25 M10 x 1.5 ------------ 40-45 ------------ 30-33 29-35 60-65 22-26 44-48 34-40 70-75 26-30 52-55 M12 x 1.75 M14 x 2 70-80 110-125 30-33 52-59 100-110 155-180 74-81 114-133 115-130 180-210 85-96 133-155 M16 x 2 M20 x 2.5 170-190 340-380 125-140 251-280 240-270 450-500 177-199 332-369 280-320 550-600 207-236 406-443 M24 x 3 580-650 428-479 800-900 590-664 900-1050 664-774 M30 x 3.5 1150-1300 848-959 1600-1800 1180-1328 1850-2100 1364-1549 M36 x 4 2000-2250 1479-1660 2800-3150 2065-2323 3250-3700 2397-2729

- 49. Inch (SAE) and Metric Fasteners M1.1 F-code Section C-code Version no T-code 000 7BWS10/13 47 Master Service Manual 2006-06-12 4. Truck Torque Specifications Description Torque Specification Drive motor end cover bolts 50 in-lbs (5.6 N•m) Gear case cover mounting bolts 200 in-lbs (22.6 N•m) (sealant, see page 107) Drive wheel lug nuts 55 ft-lbs (74.6 N•m) Drive wheel studs 23 - 28 ft-lbs (32-38 N•m) Loctite 290® Drive unit assembly 30 - 33 ft-lbs (40-45 N•m) Steering bearing 336 - 384 in-lbs (38.0-43.4 N•m) Stem mount nut 79 in-lbs (8.9 N•m) Friction disc mounting bolts 50 in-lbs (5.6 N•m) Electrical panel screws 48 - 60 in-lbs (5-7 N•m) Hydraulic motor contactor coil nut 30 - 40 in-lbs (3.4-4.5 N•m) Hydraulic reservoir clamp 48 - 60 in-lbs (5.5-7 N•m) Hydraulic unit mounting bolts 20.5 - 24 ft-lbs (28-33 N•m) Loctite 243® Hydraulic motor to adapter body 96 - 120 in-lbs (10.8-13.6 N•m) Pump to adapter body nut 100 - 134 in-lbs (11.3-15.0 N•m) Baseleg bolts 180 - 200 ft-lbs (244-271 N•m) Support arm bolts 40 ft-lbs (54.2 N•m) Truck bumper bolts 246 - 283 in-lbs (27.8-32.0 N•m) Mast mounting bolts 140 - 150 ft-lbs (190-203 N•m)

- 50. M1.1 000 7BWS10/13 Version no T-code F-code Section C-code Inch (SAE) and Metric Fasteners 48 2006-06-12 Master Service Manual 5. Conversion of Metric and English Units AREA Multiply By To Get Multiply By To Get inches² 6.451 centimeters² (cm²) centimeters² 0.155 inches² (in²) feet² 0.093 meters² (m²) meters² 10.764 feet² (ft²) LINEAR Multiply By To Get Multiply By To Get inches 25.4 millimeters(mm) millimeter 0.03937 inches (in) feet 0.305 meters (m) meter 3.280 feet (ft) yards 0.914 meters (m) meter 1.094 yards (yd) miles 1.609 kilometers (km) kilometer 0.621 miles (mi) MASS Multiply By To Get Multiply By To Get ounces (oz) 28.49 grams (g) grams 0.035 ounces (oz) pounds (lb) 0.454 kilograms (kg) kilograms 2.205 pounds (lb) tons (2000 lb) 907.18 kilograms (kg) kilograms 0.001 tons (2000 lb) tons (2000 lb) 0.907 metric ton (t) metric ton 1.102 tons (2000 lb) POWER Multiply By To Get Multiply By To Get horsepower 0.746 kilowatts (kW) kilowatts 1.34 horsepower (hp) PRESSURE Multiply By To Get Multiply By To Get pounds/in² 6.895 kilopascal (kPa) kilopascals 0.145 pounds/in² (psi) pounds/in² 0.007 megapascal (MPa) megapascals 145.04 pounds/in² (psi)

- 51. Inch (SAE) and Metric Fasteners M1.1 F-code Section C-code Version no T-code 000 7BWS10/13 49 Master Service Manual 2006-06-12 TEMPERATURE Multiply By To Get Multiply By To Get (Fahrenheit -32) 0.56 Celsius (C) (Celsius x 1.8) +32 Fahrenheit (F) TORQUE Multiply By To Get Multiply By To Get inch pound 0.113 Newton meter (N•m) Newton meter 8.851 inch pounds in-lbs feet pound 1.356 Newton meter (N•m) Newton meter 0.738 foot pounds ft-lbs VELOCITY Multiply By To Get Multiply By To Get miles/hour 1.609 kilometer/hour (km/h) kilometer/hour 0.621 miles/hour (mph) VOLUME Multiply By To Get Multiply By To Get inches³ 16.387 centimeters³ (cm³) centimeters³ 0.061 inches³ (in³) inches³ 0.016 liters liters 61.024 inches³ (in³) quarts, U.S. 0.946 liters liters 1.057 quarts, U.S. (qt) quarts, U.S. 0.83 quarts, Imp. (qt) quarts, Imp. 1.205 quarts, U.S. (qt) gallons, U.S. 3.785 liters liters 0.264 gallons, U.S. (gal) gallons, U.S. 0.83 gallons, Imp. (gal) gallons, Imp. 1.205 gallons, U.S. (gal) ounces 29.57 milliliters (ml) milliliters 0.034 ounces (oz)

- 52. M1.1 000 7BWS10/13 Version no T-code F-code Section C-code Inch (SAE) and Metric Fasteners 50 2006-06-12 Master Service Manual This page is intentionally left blank.

- 53. Technical Service Data M2.0 F-code Section C-code Version no T-code 000 7BWS10/13 51 Master Service Manual 2006-06-12 Technical Service Data NOTE! When the battery is fully charged, performance may vary due to motor and system efficiency tolerance. Technical service data represents nominal values obtained under typical operating conditions. Specifications are subject to change without notice. DRIVE UNIT Type Shunt wound Power - horsepower [hp] (kilowatts [kW]) 1.2 (0.90) Duty factor 1 hour Min carbon brush length - inch (mm) 0.59 (15) Min commutator diameter - inch (mm) 1.85 (47) Min brush - ounce-force (N•) 44.8 (12.4) Gear ratio 22:1 Oil volume, oz (liter) 13.5 (0.4) Standard operation (see page 59) temperature down to 32° F (0° C) Mobil-1 Synthetic Gear Lube 75W-90 or Texaco Synstar GL 75W-90 WHEELS Drive wheel - inch (mm) 10.0 x 5.0 (255 x 125) Drive wheel % load distribution without load (7.8” battery compartment 128” LFL Mast (7.8” battery compartment 143” LFL Mast (7.8” battery compartment 128” FFL Mast 7BWS13 62% 64.3% 64.4% Drive wheel % load distribution with maximum load (7.8” battery compartment 128” LFL Mast (7.8” battery compartment 143” LFL Mast (7.8” battery compartment 128” FFL Mast 7BWS13 29% 30.2% 27.6% Torque drive lug nut, ft-lbs (N•m) 55 (74.6) Load wheel - inch (mm) 4.0 x 3.0 (101 x 76)

- 54. M2.0 000 7BWS10/13 Version no T-code F-code Section C-code Technical Service Data 52 2006-06-12 Master Service Manual LOAD WHEELS Percent load distribution without load (7.8” battery compartment 128” LFL Mast (7.8” battery compartment 143” LFL Mast (7.8” battery compartment 128” FFL Mast 7BWS13 (EACH WHEEL) 19% 17.8% 17.8% LOAD WHEELS Percent load distribution with maximum load (7.8” battery compartment 128” LFL Mast (7.8” battery compartment 143” LFL Mast (7.8” battery compartment 128” FFL Mast 7BWS13 (EACH WHEEL) 35.5% 34.9% 36.2% HYDRAULIC UNIT Power - horsepower [hp] (kilowatts [kW]) 4 (3) Duty factor 20% on 5 min. cycles Minimum brush length - inch (mm) 0.59 (15) Minimum commutator diameter - inch (mm) 1.89 (48) Minimum brush spring tension - ounce-force (N•) 36 (10) Relief pressure - psi (bar) 3100 (213) Pump flow 2.0 cc Tank volume - gallons (liters) 1.3 (5) Standard operation (see page 59) temperature down to 32° F (0° C) Union 76 TH FUSES Keypad and ETAC Fuse 10 Amp Control Circuit Fuse 10 Amp Drive Motor Fuse 130 Amp Pump Motor Fuse 130 Amp BATTERIES Compartment Dimension L x W - inch (mm) 27.3 x 6.8 (693 x 172) Optional 27.3 x 7.8 (693 x 198) Standard 27.3 x 9.0 (693 x 228) Optional Capacity (recommended Max. Amp-hrs.) 255

- 55. Technical Service Data M2.0 F-code Section C-code Version no T-code 000 7BWS10/13 53 Master Service Manual 2006-06-12 Weight (Minimum) - lbs (kg) 330 (150) Weight (Maximum) - lbs (kg) 375 (171) Lead length - inch (mm) 18 (457) Lead position B DRIVING SPEEDS (FORKS DIRECTION) Without load - mph (kph) 3.6 (5.7) With rated load - mph (kph) 3.4 (5.4) LIFTING/LOWERING TIME (128 inch LFL [3251 mm] mast) Lift without load (fpm) 41 Lift with rated load (fpm) 22 Lower without rated load (fpm) 44 Lower with rated load (fpm) 48 AVERAGE CURRENT READINGS Driving without load (with truck on level floor) 17 Amps Driving with rated load (with truck on level floor) 30 Amps Lifting without load 61 Amps Lifting with rated load 130 Amps

- 56. M2.0 000 7BWS10/13 Version no T-code F-code Section C-code Technical Service Data 54 2006-06-12 Master Service Manual This page is intentionally left blank.

- 57. Contents, Section P P F-code Section C-code Version no T-code 000 55 Master Service Manual 2006-06-12 Contents, Section P 1. Planned Maintenance P1.0 INTRODUCTION, MAINTENANCE P2.0 SERVICE SCHEDULE P3.0 LUBRICATION CHART P4.0 OIL AND GREASE SPECIFICATIONS

- 58. P 000 Version no T-code F-code Section C-code Contents, Section P 56 2006-06-12 Master Service Manual This page is intentionally left blank.

- 59. Introduction, Maintenance P1.0 F-code Section C-code Version no T-code 000 7BWS10/13 57 Master Service Manual 2006-06-12 Introduction, Maintenance The schedule of maintenance and lubrication given in this section of the service manual cover up to one year’s operation of the truck. These schedules are based on hourly usage and can be adapted to suit most schedules. The following hourly usage figures have been used when calculating the schedule: Single shift, 30 hours per week usage Double shift, 60 hours per week usage Triple shift, 90 hours per week usage The “Planned Maintenance Schedule” on page 61 is based on the single shift schedule. The schedules are intended only as a guide, not as a rigid structure. Owners of the trucks may wish to adapt to local requirements; but it is emphasized that the schedules represent minimum manufacturer requirements, and all items should be included in a service program to ensure minimum downtime and a high status of the equipment. • Use spare parts approved by Toyota. • Always clean the equipment and carry out a full check after service.

- 60. P1.0 000 7BWS10/13 Version no T-code F-code Section C-code Introduction, Maintenance 58 2006-06-12 Master Service Manual 1. Jacking Truck Off The Floor To perform maintenance that requires the truck to be lifted from the floor, observe the proper precautions as follows: 1. Lower the forks completely. Remove any load. 2. Press the red OFF (O) key on the keypad. Disconnect battery connector from the truck. 3. If possible, stabilize the top of the mast with an overhead chain hoist. 4. Position the jack under the designated jacking points. 1.1. Elevate Rear of Truck 1. Place jack in the designated jacking position. 2. Jack the truck so that the drive tire is off the floor no more than 3.0 inch (76 mm). 3. Block the truck in place. Use extreme care whenever the truck is jacked up for any reason. Never block the truck between the mast column and the floor. Use a suitable hoist to stabilize the mast. Keep hands and feet clear from beneath the truck while jacking. After the truck is jacked, position solid blocks beneath it to support it. DO NOT rely on the jack alone to support the truck. WARNING

- 61. Introduction, Maintenance P1.0 F-code Section C-code Version no T-code 000 7BWS10/13 59 Master Service Manual 2006-06-12 1.2. Elevate Either Side of Truck 1. Place jack in the designated jacking position. 2. Jack the side of the truck so that the load wheel is off the floor no more than 0.50 inch (12.7 mm). 3. Block the truck in place. 2. Lubricants 2.1. Standard The standard conditioning truck is designed for operation in temperatures down to 32 degrees F (0 degrees C). Figure 0-1: Jacking Truck Off the Floor Jack only in these areas Jack under frame only. “DO NOT Jack directly on mast.

- 62. P1.0 000 7BWS10/13 Version no T-code F-code Section C-code Introduction, Maintenance 60 2006-06-12 Master Service Manual This page is intentionally left blank.

- 63. Service Schedule P2.0 F-code Section C-code Version no T-code 000 7BWS10/13 61 Master Service Manual 2006-06-12 Service Schedule 1. Planned Maintenance Schedule ITEM WORK REQUIRED Time Interval Moderate Usage 1 Day 8 Hrs. 6 Months or 500 Hrs. 12 months or 1000 Hrs. Check Severe Usage 1 Day 8 Hrs. 3 Months or 250 Hrs. 6 months or 500 Hrs. General 1 Check for loose hardware. Tighten as necessary. X 2 Note any unusual noise during operation. X 3 Check for leaks around drive unit and hydraulic system. X 4 Visually inspect all cables for damage. X 5 Check grease location points (See Section P4.0 for locations and specific Section S.0 for information.) X 0300 Chassis 0300.1 Check truck data plate and decals for legibility. X 0300.2 Check for crack formation and damage. X 1700 Motors 1700.1 Check connections for proper contact. X 1700.2 Clean motor of dirt and dust. X 1700.3 Check condition of brushes, springs, and holders. X 1700.4 Check brush length. Replace brushes if necessary (see page 90.) X 2550 Drive Unit 2550.1 Check oil in drive housing. Check for contamination in the oil (see page 102.) X 2550.2 Change transmission oil (see page 101.) X 3300 Brake 3300.1 Check brake operation. X 3300.2 Clean dust and debris. X 3300.3 Check brake disc for wear. X 3500 Wheels 3500.1 Remove all string, wrapping, and debris. X 3500.2 Check all wheels for wear. X 4100 Tiller Arm 4100.1 Check return of tiller arm to upper rest position. X 5000 Electrical Control System 5000.1 Check operation of horn button. X 5000.2 Check speed and thumb controls. X 5000.3 Check tiller arm/angle switches for adjustment. X

- 64. P2.0 000 7BWS10/13 Version no T-code F-code Section C-code Service Schedule 62 Master Service Manual 2006-06-12 5000.4 Check steering operation. X 5000.5 Check lift/lower functions. X 5000.6 Check operation of main ON/OFF switch. X 5000.7 Check for electrical shorts in chassis. X 5000.8 Check operation of reverse button. X 5110 Battery 5110.1 Check cleanliness and exterior conditions. X 5110.2 Check the battery charge. X 5110.3 Check the battery weight. X 5110.4 Check all connections; battery, battery and charger plugs. X 5110.5 Check battery mounting bolt or freeplay. X 5111 Battery Connector 5111.1 Check battery connector. Make sure all powered functions shut down when disconnected. X 5400 Electrical Panel 5400.1 Clean and check mounting to chassis. X 5400.2 Check contactors for welded conditions. X 5400.3 Check contactor tips for free movement. X 6000 Hydraulic System 6000.1 Check hoses for wear and damage. X 6000.2 Check reservoir for cracks, leaks, and mounting. X 6000.3 Check for correct oil level. X 6000.4 Check hydraulic connections and mounting. X 6000.5 Change hydraulic oil. Clean filters. X 7100 Mast 7100.1 Check for damage and cracks. X 7100.2 Check clearance of rollers. Check rollers for unusual wear patterns. X 7100.3 Check lateral play of inner section. X 7100.4 Check for wear on lift chains and chain rollers. X 7100.5 Check adjustment of lift chains. X 7100.6 Clean and lube lift chains. X 7100.7 Clean and lube mast columns. X 7100.8 Lube chain sheaves. X ITEM WORK REQUIRED Time Interval Moderate Usage 1 Day 8 Hrs. 6 Months or 500 Hrs. 12 months or 1000 Hrs. Check Severe Usage 1 Day 8 Hrs. 3 Months or 250 Hrs. 6 months or 500 Hrs.

- 65. Service Schedule P2.0 F-code Section C-code Version no T-code 000 7BWS10/13 63 Master Service Manual 2006-06-12 7400 Lift Device 7400.1 Check clearance of fork carriage/yoke rollers. X 7400.2 Check fork carriage/yoke for damage and crack formation. X 7400.3 Check forks for wear and cracks. X ITEM WORK REQUIRED Time Interval Moderate Usage 1 Day 8 Hrs. 6 Months or 500 Hrs. 12 months or 1000 Hrs. Check Severe Usage 1 Day 8 Hrs. 3 Months or 250 Hrs. 6 months or 500 Hrs.

- 66. P2.0 000 7BWS10/13 Version no T-code F-code Section C-code Service Schedule 64 Master Service Manual 2006-06-12 5110 5400 5110 5000 1700 6000 3500 3300 2550 5700 4100 1700