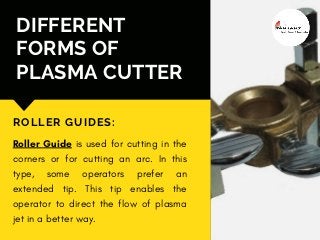

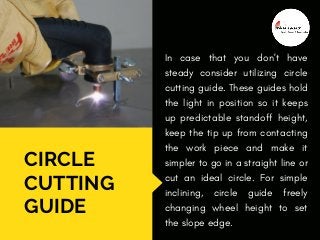

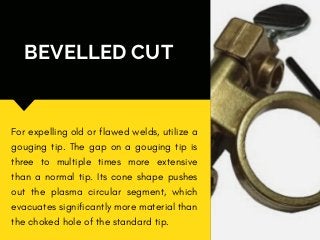

If you want to know about plasma cutting tool, then read this document to know about the plasma cutting tool & its different forms to use in different mechanical machine. If you want to buy plasma cutting tool like roller guide, circle cutting guide and more, then visit online store of Tanjant Tool Co. Pty. Ltd today.