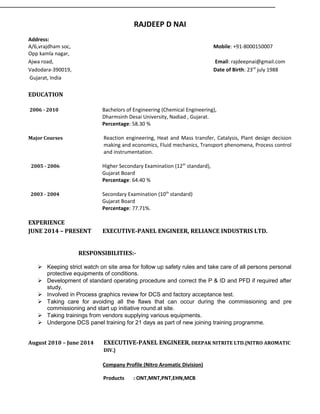

Rajdeep D Nai Resume

- 1. RAJDEEP D NAI Address: A/6,vrajdham soc, Mobile: +91-8000150007 Opp kamla nagar, Ajwa road, Email: rajdeepnai@gmail.com Vadodara-390019, Date of Birth: 23rd july 1988 Gujarat, India EDUCATION 2006 - 2010 Bachelors of Engineering (Chemical Engineering), Dharmsinh Desai University, Nadiad , Gujarat. Percentage: 58.30 % Major Courses Reaction engineering, Heat and Mass transfer, Catalysis, Plant design decision making and economics, Fluid mechanics, Transport phenomena, Process control and instrumentation. 2005 - 2006 Higher Secondary Examination (12th standard), Gujarat Board Percentage: 64.40 % 2003 - 2004 Secondary Examination (10th standard) Gujarat Board Percentage: 77.71%. EXPERIENCE JUNE 2014 – PRESENT EXECUTIVE-PANEL ENGINEER, RELIANCE INDUSTRIS LTD. RESPONSIBILITIES:- Keeping strict watch on site area for follow up safety rules and take care of all persons personal protective equipments of conditions. Development of standard operating procedure and correct the P & ID and PFD if required after study. Involved in Process graphics review for DCS and factory acceptance test. Taking care for avoiding all the flaws that can occur during the commissioning and pre commissioning and start up initiative round at site. Taking trainings from vendors supplying various equipments. Undergone DCS panel training for 21 days as part of new joining training programme. August 2010 – June 2014 EXECUTIVE-PANEL ENGINEER, DEEPAK NITRITE LTD.{NITRO AROMATIC DIV.} Company Profile (Nitro Aromatic Division) Products : ONT,MNT,PNT,EHN,MCB

- 2. Technology : MARIO BIAZZI (SWITZERLAND) and BEFS (FRANCE) DCS : FOXBORO-USA (LATEST VERSION 8.2.2) RESPONSIBILITIES:- Controlling of process parameters through DCS. Debottlenecking & Trouble shooting for smooth operation. Minimize down time by timely corrective action. To check QC reports and take require action. Monitoring plant production & maintenance activity. Handle the plant independently during power interruption. Knowledge of plant start up & shut down. Investigate problems and recommend solutions. To achieve production as per Budget plan so as to meet requirement of marketing. PROCESS: It involves continuous Nitration of Toluene through CSTR in series followed by Distillation column to remove Ortho – isomers and Melt Crystallization to remove Para,Meta – isomers. It involves continuous Nitration of EHA. INTERNSHIPS/TRAININGS UNDERGONE: Sulphuric acid -4 Plant, Gujarat state fertilizer corporation Ltd & Mono Chloro Benzene plant, Deepak Nitrite Ltd., Vadodara, Gujarat, India 1. Understanding of the process. 2. Detailed understanding of Process variables 3. First-hand experience on heat exchangers, distillation column, furnaces. HOBBIES: Playing cricket, Playing chess, Listening music. Present CTC : 5.2 lacs per annum Expected CTC : 7.5 lacs per annum SKILLS: • Languages : English, Hindi & Gujarati • Technical : Excellent trouble shooting skills, finding a root cause of the problem, • Other : Strong interpersonal skills, Good team player, Can work in any type of Environment, continuously until problem is solved. REFERENCES: Krunal Amin, Assistant Professor, Chemical Engineering Department, GSAT, Vallabh Vidyanagar, India , Email: kgamin88@gmail.com • Phone: +91-9924449548 Ketan Vankar,Dy Manager,Essar oil ltd.,Phone:+91-8238029833