current resume

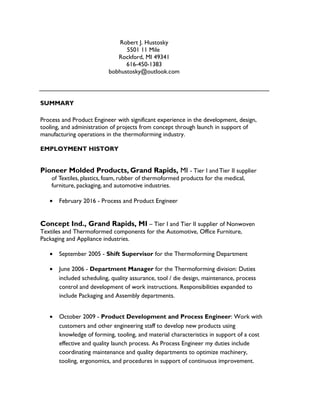

- 1. Robert J. Hustosky 5501 11 Mile Rockford, MI 49341 616-450-1383 bobhustosky@outlook.com SUMMARY Process and Product Engineer with significant experience in the development, design, tooling, and administration of projects from concept through launch in support of manufacturing operations in the thermoforming industry. EMPLOYMENT HISTORY Pioneer Molded Products, Grand Rapids, MI - Tier I and Tier II supplier of Textiles, plastics, foam, rubber of thermoformed products for the medical, furniture, packaging, and automotive industries. • February 2016 - Process and Product Engineer Concept Ind., Grand Rapids, MI – Tier I and Tier II supplier of Nonwoven Textiles and Thermoformed components for the Automotive, Office Furniture, Packaging and Appliance industries. • September 2005 - Shift Supervisor for the Thermoforming Department • June 2006 - Department Manager for the Thermoforming division: Duties included scheduling, quality assurance, tool / die design, maintenance, process control and development of work instructions. Responsibilities expanded to include Packaging and Assembly departments. • October 2009 - Product Development and Process Engineer: Work with customers and other engineering staff to develop new products using knowledge of forming, tooling, and material characteristics in support of a cost effective and quality launch process. As Process Engineer my duties include coordinating maintenance and quality departments to optimize machinery, tooling, ergonomics, and procedures in support of continuous improvement.

- 2. • Hands-on experience includes: Products and manufacturing techniques involving carding of man-made and natural fibers, in-line and rotary forming, pressure forming, and lamination for both cold set and heat set polymers. • Customer interaction at Concept includes Ford, GM, FCA, Toyota, Autoneum, Hayashi, Steelcase, HNI, and Whirlpool. Ameriform, Muskegon, MI - Thermoforming and sheet extrusion manufacturer servicing packaging, automotive, marine and various other industries. • January 1991 – Supervisor: 3rd shift manager with a crew of 3, running a single rotary thermoforming machine. • March 1994 - Plant Manager: Thermoforming Plant Manager with the responsibilities of scheduling for both machinery and people, part quality, cycle time & material cost efficiencies, and employee training for 3 shifts with a crew of between 60 and 80 employees. • May 2003- Process Engineer: Developed expertise in vacuum, twin sheet and pressure forming processes. Responsible for thermoforming machine design, sheet extrusion (Polyethylene), CNC trimming, pattern making, mold design, and fixture design. Served as company liaison /off-site consultant with customers including G.E. Plastics, Magna, Guardian, and Avery. Other customer support included Water Craft, Sportsman, and Porta-Jon. Other Ameriform markets included custom forming for the home and garden industry, items such as hot tubs wheel barrow, and lawn spreaders. Stack Pack Corp., Grand Rapids, MI – Thermoforming manufacturer / supplier to various packaging and BOM customers. • March 1986 - Lead Operator: During my time at Stack Pack I began to learn the Thermoforming process and was trained in set-up of various types of thermoforming machines, and presses used for die cutting. When I left in 1991 my job title was Operator / Set-up Lead.

- 3. EDUCATION & TRAINING • Business Management, GRCC, Grand Rapids, MI, 2 years • Business Management, GVSC, Allendale, MI, 1 year