FinalReport

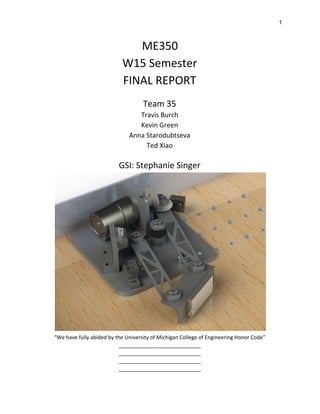

- 1. 1 ME350 W15 Semester FINAL REPORT Team 35 Travis Burch Kevin Green Anna Starodubtseva Ted Xiao GSI: Stephanie Singer “We have fully abided by the University of Michigan College of Engineering Honor Code” ____________________________ ____________________________ ____________________________ ____________________________

- 2. 2 Section 1: Project Introduction Section 2: Design Processes Section 3: Design Selection Section 4: Final Linkage Design Section 5: Final Team CAD Section 6 : Final Team ADAMS Section 7: Motion Generator Revision: Section 8: Evaluation of Received Designs for Manufacturing: Section 9: Evaluation of Received Manufactured Parts: Section 10: Energy Conversion Introduction: Section 11: Transmission Ratio Determination: Section 12: Transmission Type Selection Section 13: Final Transmission Design: Section 14: Power Analysis: Section 15: Torque Transfer Analysis: Section 16: Deflection Analysis Section 17: Safety & Motor Controls Introduction Section 18: Capabilities & Limitations of Sensors Sensor 19: Mounting Considerations & Methods Section 20: Encoder Counts, IR Sensor Threshold, and Controller Gains Section 21: Arduino Code Changes Section 22: Final Testing Results Section 23: Design Critique & Evaluation Appendix A: Individual Sketch Relations Design, 3D Solidworks, and ADAMS Analysis Appendix B: Drawings, Manufacturing Plans, Bill of Materials, and Assembly Plan for Final Design Appendix C: Approval Packages, Bill of Materials, and Assembly Plan for Transmission Design Appendix D: Wiring Diagram, Arduino Code, Calculations, and Bill of Materials for Safety & Motor Controls Section 1: Project Introduction The overall goal of this project is to design, build, and test a device that reflects a laser onto a target by quickly moving a mirror attached to a mechanism with a linkage. The lasers can be shot from four different lanes in varied order. The mechanism must detect the lane that the laser is coming from and position the mirror so that the laser is reflected onto the target as quickly and accurately as possible. The motivation of the project is to improve our understanding of motion generation, energy conversion and transmission, as well as motor control. The mechanism must be mounted to holes at the bottom right of the playing field. There are two sizes of mounting holes spaced out in an alternating pattern along an 8”x6” grid. The holes located in the

- 3. 3 corners of the grid will be ⅜” - 16 threaded holes and the others will be dowel holes for alignment. The main part of mechanism itself will be a linkage that needs to be able to attain a range of motion large enough to be able to reflect the light from the mirror onto the target from any of the lasers on the arena. Additionally, the mechanism needs a platform to hold the linkage, motor, and various sensors that can be secured on to the arena into the provided holes. Hard stops need to be built into our mechanism to ensure the linkage does not rotate past its intended range of motion. The transmission will be able to rotate our mechanism to the desired positions quickly and with as little friction as possible. Figure 1.1: ME 350 playing field dimensions An Arduino will be programmed to detect the laser light when it is activated and will correspondingly move to the location of the laser. We will program a laser target sensor to detect whether or not the laser is actually reflected on to the target along with a proximity sensor that stops the mechanism when it comes too close to an object or the boundaries of the arena. Limit switches are also provided to send the Arduino a signal that the maximum range of motion has been achieved. The craftsmanship of the mechanism will be evaluated in terms of safety, alignment, sturdiness, quality of design and manufacturing, use of spacers, and aesthetics. The mechanism needs to have all burrs and sharp edges filed down, all fasteners protruding no more than 1.5 times its diameter, and must avoid pinch points if possible. All parts should be well aligned with one another and should have minimal play or friction between each part. Each part should also be easy to access with tools and

- 4. 4 easily manufacturable. The surface must be finished to give the mechanism a more professional appearance and improve performance, as well as be aesthetically appealing overall. Lastly, stacked washers cannot be used; instead, a self-manufactured part should be made that matches the dimensions of the space. The performance of the mechanism will be evaluated through volume, transmission angle, reflection accuracy, steady state error, laser detection percentage. The volume must be as small as possible and cannot exceed 2500 cubic centimeters. The transmission angle should deviate as little as possible and should remain within 30 to 150 degrees. The mechanism should be able to reflect as close to 100% of the light as possible on to the target. The steady state error is the average distance from the center of the laser light to the center of the target and should be minimized. The laser detection percentage is the total amount of time the laser is detected divided by the total test time and should be as close to 100% as possible. Table 1.1: Design scoring criteria All teams are required to use the motor provided and may not connect it to a power source greater than 9V. Additionally, the mechanism is constrained to be a maximum of 25000 cubic centimeters. The location of the mounting holes is also a restriction in that the mechanism cannot be mounted anywhere else. Section 2: Design Processes We generated our individual designs by creating a Solidworks sketch that encompassed the project requirements. The key requirement is the ability to reflect the four lasers at the target. We created a copy of our four bar linkage for each laser. Each of these four copies represented one position of the mechanism. The four versions were made to be equivalent by forcing the ground link to be identical between all four and defining the length of each linkage to be the same between positions.

- 5. 5 To describe the behavior of the lasers and the mirrors we used the relation that the angle of incidence is equal to the angle of reflectance. We forced the mirrors to be in an acceptable orientation by constraining the laser beam to strike the mirror and for the reflection to go directly to the center of the target. The mirror is then constrained to be perpendicular to the line that bisects the angle between the laser beam hitting the mirror and the laser beam hitting the target. One notable thing that we changed from the instructions we received is that we removed a major unnecessary constraint. The initial instructions told us to force the mirror to reflect each laserbeam from the exact center of the mirror. We saw this constraint as unnecessary and by removing it we were able to greatly reduce the size of the mechanism. We had to be careful that all four laser beams struck the mirror surface within 2 inches of each other because there is not a hard constraint in the model to ensure that the lasers strike the mirror plane in a place where the mirror is. Figure 2.1: Solidworks model of linkage layout Then we freely moved the ground pivots and the transmission angles to change the properties of the four bar linkage. Because we decreased the number of constraints on the system we were able to substitute our own. We defined the two extremes of the transmission angles and then dragged the ground pivots. We tried to minimize the volume the device operates inside while forcing the maximum transmission angle deviation from 90 degrees to be small. We used ADAMS to give us a relatively accurate simulation of how much torque and power we would need to drive our links through their full range of motion. In order to do so, we had to import our model, create points and joints to constrain the links, and apply a motion to the driven link.

- 6. 6 Figure 2.2: Final ADAMS Model for the linkage Section 3: Design Selection In order to select the optimal design we used a Pugh selection matrix with several criteria like Volume, Transmission angle, Speed, etc. We chose the first four criteria detailed in the Table 3.1 because they are the the major scoring criteria that will be measured on our device. The simplicity criteria includes aspects like machinability and ease of assembly. This was included because of the time limit that we have to assemble our device on the table as well as the machining quality and time that will come from a simpler design. Table 3.1: Pugh selection matrix for linkage design selection Volume Transmission Angle Speed Accuracy Simplicity Total Weight 8 7 9 6 4 Normalized Weight 2.000 0.212 0.074 0.600 0.400 Kevin 3.45 4 121.25 8 9 25.093 Anna 2.3 29.7 53.75 9 9 23.865 Ted 0.5925 31.58 79.04 8 9 22.114 Travis 0.305 28.2 50.49 10 9 19.917 Combined 3.7925 32.03 112.42 9 8 31.272

- 7. 7 We initially weighed each criteria based on the the ultimate number of points available in addition to the feasibility of criteria optimization, thus taking into account the diminishing returns of full optimization. Each of these initial weights were normalized to max value in the range. Optimizing the speed and volume criteria is inversely proportional to link length while the optimization of the transmission angle is proportional with link length. Thus, we assigned speed and volume higher weights in comparison to the transmission angle in the hopes to optimize two criteria in place of just one. With all scores weighted and summed the combined design had the highest total value and was selected as our design. The volume was approximated as the smallest possible area taken up by the links for each individual linkage system. This was done under the assumption that our basic assembly would remain constant regardless of the linkages. Transmission angle was included because it is one of the criteria that our device will be scored on. The ability of our device to perform quickly was approximated using the longest link length squared as a representation of the rotational inertia of the links, which will limit the speed of rotation at a supplied power. The accuracy criteria is an important aspect of the design yet could only be assigned arbitrarily. Our arbitrary assignments were based on the length of the input link. This was done because a shorter input link will have a smaller error in translational displacement at the coupler link. The approximated values found in Table 3.2 were used in the pugh chart and were collected using Solidworks and ADAMS. Table 3.2. Design summary specifications for individual designs Power (lb*in/s) Volume (in^3) Max Transmission Angle Deviation Kevin 0.5 5.55 56 Anna 0.84 6.7 30.3 Ted 0.41 8.4075 28.42 Travis 0.14 8.695 31.8 Combined 0.31 5.2075 27.97 Section 4: Final Linkage Design Table 4.1: Final design link lengths Link Name Length (inches) Input Link 5.619 Coupler Link 2.300 Follower Link 4.859

- 8. 8 Table 4.2: Final design transmission angles Lane Position Transmission Angle (deg) Transmission Angle Deviation(deg) Lane 1 117.97 27.97 Lane 2 100.11 10.11 Lane 3 80.79 9.21 Lane 4 63.00 27.00 The following table describes our final ground pivot locations relative to the top left bolt hole in the mounting grid. Positive is being defined as to the right for X and towards the lasers for Y. Table 4.3: Mechanism ground pivot locations relative to top left mounting hole Ground PIvot Locations Input Output X 5.01 7.48 Y -1.90 -3.64 Figure 4.1: Pivot locations

- 9. 9 On our platform, we have two press-fit dowel pins on opposite sides of the platform to ensure a precise and consistent mounting of the platform. There will also be ⅜”-16 bolts to secure this baseplate to the table, ensuring that it doesn’t move. This part will be made of ¼” aluminum plate so that it has enough depth for other parts to be threaded into it. The input and output links are both going to be made from ⅛” inch aluminum plate to keep the weight as low as possible while still maintaining stiffness. The aluminum will hold high tolerances around the pivot locations to prevent slop during rotation. We will press-fit bronze bushings into the pivot locations and sandwich needle thrust bearings between the joints and the bolt to reduce friction. We considered using aluminum, acrylic, nylon and acetal for our coupler link. We eliminated aluminum and acrylic because of their high frictional coefficients of 0.38 and 0.3-0.7 respectively. We chose between Oil-Filled Cast Nylon and PTFE-Filled Delrin Acetal Resin by comparing a number of different factors. The nylon is 26% denser than acetyl, but this only turns into a difference of 3.7 grams for our coupler design. The acetyl has slightly better range of frictional coefficients, between 0.07 and 0.14 compared to the Oil-Filler Cast Nylon of between 0.12 and 0.15 . An important consideration is the ability to glue the mirror to the part. We found that Delrin Acetal Resin is notoriously difficult to glue to. Nylon was known to be relatively difficult but worked well with two part epoxy. We thought that the ability to glue to the part was more important than the weight increase and the small friction increase, and decided to make our link out of Oil-Filled Cast Nylon. It will have a similar joint design to the input and output links. Our hardstops will be made out of neoprene rubber because it can absorb shock without damaging the links while providing a rigid stopping location. The joint between the coupler and input and output will utilize needle bearings, bronze bushings, and spacers. The spacers are used to distribute the load across the needle bearings, which will reduce friction. The bronze bushings that are press-fit into the links also reduce friction between the bolt and the link during rotation. Our coupler link is made out of nylon, which also has a low coefficient of friction. The joint between the platform and the links employs the same use of washers to distribute the load over the needle bearing in addition to the use of bronze bushings. We can place spacers at our ground pivots on the platform or at the pivots at the coupler to raise the mirror.

- 10. 10 Section 5: Final Team CAD Beginning of Motion End of Motion Figure 5.1: Solidwork images showing the beginning and end of the linkages motion with the links labeled Figure 5.2: Solidworks Isometric view of the Linkage on the playing field

- 11. 11 Coupler-Input Joint Input-Ground Link Figure 5.3: Cross sections of the ground and coupler links with components labeled Figure 5.4: Image showing the dimensions for overall volume of mechanism Section 6 : Final Team ADAMS Our acceleration profile was at 2019.1 degrees per second squared. In order to calculate this, we had to fit a triangular velocity profile that has a period of constant acceleration then constant deceleration. Our linkage had to rotate 54.97 degrees, and to calculate the required angular acceleration, we plugged that value into the equation below. The simulation time we chose was a third of a second because the laser lane will switch as soon as we reflect the light onto the mirror, so at worst the linkage will have to move from the first to the fourth lane. A third of a second seemed like a reasonably quick time to move the linkage through this motion

- 12. 12 Figure 6.1: ADAMS model of final linkage The angular position moves consistently in a manner similar to a parabolic function, which is to be expected from constant acceleration. Figure 6.2: Angular position graph for the input link from ADAMS simulation The angular velocity graph is also as expected, as there is a period of constant acceleration followed by a period of deceleration after the midway point.

- 13. 13 Figure 6.3: Angular velocity graph for the input link from ADAMS simulation The power curve seems to make sense as well. Initially the power required is going to steadily increase as the linkage is being accelerated, and as soon as the point of deceleration begins, the power drops to zero. As the deceleration happens, however, the motor will need to engage a little bit to ensure a constant deceleration. Figure 6.4: Power graph for the mechanism from ADAMS simulation The input torque graph also seems reasonable, as in the beginning, there is a larger torque required to start the movement of the mechanism, and as soon as the deceleration begins at 0.165 seconds, the torque goes to almost zero. As the deceleration moves along, a little torque will be necessary to maintain a constant deceleration.

- 14. 14 Figure 6.5: Torque graph on the input link from ADAMS simulation Section 7: Motion Generator Revision Our link lengths and transmission angles have not changed. However, we have made cutouts in our links to reduce weight while maintaining stiffness. The cutouts are designed in such a way that the cutouts will start at the point of contact of the hard stop to ensure that the links do not deform upon impact with the hard stop. We have added several washers at our ground pivots to raise the links high enough off of the baseplate to clear the head of the bolts that secure the baseplate to the table. These washers will also help to distribute the force across the entire face of the needle bearing. Finally, one of our ground pivot spacers was thinned at one end to be able to accommodate the gear that we expect to use in our transmission. Our revisions didn’t change the length of the links, but we did add cutouts in the links to reduce weight. After fixing the ADAMs model and running our acceleration profile again, the power consumption decreased by about 0.5 pound-inches per second and input torque decreased by about 0.12 pound inches. Section 8: Evaluation of Received Designs for Manufacturing Team 4’s manufacturing drawings were satisfactory aside from the tolerances they put on each drawing. They had tolerances of 0.01 inches for all two decimal place dimensions and 0.001 inches for all three decimal place dimensions. These tolerances were too close for the purposes of this class, so we convinced them to increase the tolerances to 0.02 inches and 0.005 inches for two decimal place and three decimal place dimensions respectively. They should add trusses at the locations of the hard stops and through the entire slot to improve stiffness and strength in case of hard impact and add fillets at corners of the slots in the links to reduce those stress concentrations. Waterjet tolerances are also not great, so mounting the mirror inside the coupler link may be difficult if the fit isn’t correct. Lastly, adding needle bearings under the input and output link at the coupler joints would reduce friction at the pivot locations.

- 15. 15 Section 9: Evaluation of Received Manufactured Parts The manufactured parts were extremely satisfactory for the most part. The dimensions were correct and the tolerances were within the ranges that we specified. The most critical error was that instead of making the coupler out of nylon as the manufacturing plan called for, the manufacturing team made the coupler out of aluminum angle stock. We were running out of time, so our team decided to manufacture the correct coupler out of nylon ourselves. Also, one of the holes on the links ended up slightly oversized, so the bronze bushing can easily slide in and out. This causes issues when assembling the linkage, as the shoulder screw can’t fit through without pushing the bushing out of the hole. We resolved this by deburring the inside face of the bushing to allow the shoulder screw to more easily slip through the hole. Section 10: Energy Conversion Introduction A transmission will be used to translate the motion output from our motor to the input link in order to move the linkage. A transmission is necessary because it provides us flexibility in how we convert the power from the motor into the rotational motion needed for the linkage. The transmission can be used to convert the torque output from the motor to a more desirable torque that suits the design of our mechanism by increasing or decreasing its ratio. An increase in the transmission ratio correlates to a proportional increase in the torque and a proportional decrease in the speed, and vice-versa when the transmission ratio is decreased. Space is usually one of the biggest limits of a general transmission design, as the transmission always must fit within a certain space provided. In our case, this is an issue, as we must be clear the back wall of the arena and mustn’t interfere with the motion of the linkage either. There will also be losses in output speed and torque because most transmissions do not have 100% efficiency. In this project, the motors provided produce low torques and high speeds, so we need to use a transmission with a reduction n; however, we can’t make nextremely large because of the load inertia of the motor, so we will have to use load-inertia matching to find the optimal transmission ratio. Section 11: Transmission Ratio Determination To determine the gear ratio, we used the method of inertia matching. The idea is that the motor can deliver the most power to the mechanism when the gear ratio is such that self inertia of the motor is equal to the virtual inertia of the linkage. We can alter the gear ratio (n) to change the virtual inertia of the linkage. We can calculate the ideal ratio by calculating the inertia of the linkage and taking the square root of the ratio between that and the motor. The first step is to calculate the moment of inertia of the linkage. This is not trivial because as the linkage moves, its moment of inertia also changes. First, we quantify the geometry of the linkage in different states. The following table contains the values for our linkage at five different positions. The values are labeled as they are in the corresponding image.

- 16. 16 Figure 11.1: Model of the linkage with instant centers and distances labeled Table 11.1: Table showing the geometric properties of different linkage positions Transmission Angle (deg) R1 (cm) R2 (cm) R3 (cm) R4 (cm) R5 (cm) Position 1 117.97 14.27 30.00 32.29 12.34 31.03 Position 2 100.11 14.27 43.39 44.03 12.34 43.62 Position 3 90.00 14.27 51.55 51.22 12.34 51.30 Position 4 80.79 14.27 58.27 58.06 12.34 58.60 Position 5 63.00 14.27 75.31 72.48 12.34 73.85 From our CAD model we found the mass and moment of inertia values for components that move in our linkage. For the joint hardware we assumed that it has a negligible moment of inertia. We took these mass and center of mass moments of inertia and used the geometric variables to calculate their moment of inertia around their center of zero velocity with respect to the ground. We did this using the parallel axis theorem.

- 17. 17 Table 11.2: Table showing the mass and inertia properties of different components of the linkage Component Mass (gram) Center of Mass Moment of Inertia (gram cm^2) Input Link 19.28 478.49 Coupler Link 14.33 33.431 Mirror 20.21 51.95 Follower Link 16.21 321.56 Coupler-Input Joint 10 Negligible Coupler- Follower Joint 10 Negligible We then calculated a scaling factor to account for the differences in the angular velocities of the different links. These scaling factors are a ratio of the link’s angular velocity to the input link’s angular velocity. To find the total moment of inertia we summed each links moment of inertia times its scaling factor squared. When we did that we found that: Itotal= 15300 g*cm2 To get the gearing ratio we used the formula for the gearing ratio that gives the highest power transfer. Jmotor is the moment of inertia of the motor which is either 16000 for the 18.75:1 gearing or 25000 for the 29:1 gearing. n2 = Itotal/Imotor When we calculated the gear ratio we got the following options for the 18.75:1 and the 29:1 respectively: n1= 0.978 n2= 0.783 N1is appealingly close to a 1:1 gear ratio. We are ignoring the inertia of the gearing itself which will push the ideal gear ratio closer to 1:1. The other factor that is important to us is the resolution of the encoder. We know that the 19.75:1 motor has a 64 count per revolution encoder on the motor shaft. This is then increased to 1200 counts per revolution on the gearbox output. If we use a 1:1 gearing this would mean that one count would correspond to 0.3 degrees, which we decided would be sufficient for our purposes. Section 12: Transmission Type Selection In order to select the optimal transmission design, we used a Pugh selection matrix with several criteria like: Added Volume, Resolution, Gear Ratio and Simplicity. The resolution will affect the accuracy of our mechanism, which is another one of the major scoring criteria. The gear ratio criteria is included because the ability to closely match the ideal gear ratio will determine how well the power

- 18. 18 provided to the motor will be used. The simplicity criteria includes aspects like ease of sourcing and ease of assembly. This was included to account for machining quality and time that will come from a simpler design. Table 12.1: Pugh selection matrix for transmission design Added Volume Resolution Gear Ratio Simplicity Total Weight 8 6 9 4 Normalized Weight 0.160 0.167 0.900 0.400 Bevel Gears 47.0 24 10.0 8 23.720 Timing Belts 2.6 36 10.0 8 18.616 Spur Gears 2.6 20 10.0 9 16.349 We initially weighed each criteria based on the the ultimate number of points available in addition to the feasibility of criteria optimization, thus taking into account the diminishing returns of full optimization. Each of these initial weights were normalized to max value in the range. Optimizing the gear ratio will affect everything that follows, so that criteria was given the highest nominal weight. The volume is an area that we hope to gather the majority of our final points from, so we continued to assign this a rather high weight as well. The resolution of the encoder on the motor is 0.3 degrees per step, which will be plenty for our 1:1 gear ratio, so this was a criteria that was not weighted as heavily. The simplicity of assembly and sourcing was given the lowest weight because of the flexibility of our original design as well as the numerous sources to find transmission components. The added volume was approximated as the base area multiplied by the expected height of the transmission that passed beyond the original height of the mechanism. This was done under the assumption that our basic assembly would remain constant regardless of the transmission chosen. The resolution of the transmission was approximated using the pitch of the various transmission designs because a higher pitch means a greater number of teeth per angle, giving a higher resolution. The gear ratio difference is the inverse of the ideal gear ratio (the achievable gear ratio), giving us a higher value for gear ratios closer to the ideal ratio. The simplicity criteria was scored qualitatively based on the ease of finding the parts online that fit our design criteria and was also gauged by the number of components that would be needed for the transmission to function. With all of the design criteria summed, the bevel gears had the highest weighted score on the Pugh chart and were chosen for our final design. The bevel gears selected for the transmission are supplied by McMaster-Carr and have part number (729K16). Section 13:Final Transmission Design The final transmission design incorporates nylon bevel gears as our means of transferring torque to the links from the motor. They are light but rigid and will be easy to alter for our mechanism. There will be one driven gear mounted above the link coaxially with the link pivot. The gear will be pinned

- 19. 19 directly to the link with 1/16” steel roll pins and will be between two needle bearings. To make room for the addition of the gear, we removed the spacer above the link and will slightly reduce the height of the spacer that lies beneath the input link. Figure 13.1 Cross section of input joint showing dowel pin The driving gear will be mounted above the driven gear with their axes perpendicular and their teeth properly meshed as shown in Figure 13.2. The bore of the gear is slightly larger than the shaft of the motor, so we will have to drill out the bore of the gear and add an aluminum insert that will have room for a set screw on the shaft as well as a roll pin that will secure the gear to the insert. Figure 13.2 Cross section of input link showing gear meshing and isometric view of meshed gears The motor is mounted on an L-bracket with slots on the base for horizontal adjustability. The vertical adjustability was added later by slotting three of the screw holes and the motor shoulder hole. We chose to only slot three of the hole because we thought that 3 would be enough to secure our motor while not compromising any strength in the bracket. The natural taper of the bevel gears will provide some added flexibility when aligning the gears.

- 20. 20 Figure 13.3 Image showing the motor mounting bracket The addition of the bevel gears and the rest of the transmission will substantially increase the volume from the previous 51.8 in^2 to 98.2 in^2. This adds 46.4 in^2, which is mostly due to the fact that the entire base area has to be multiplied by the added height. Section 14: Power Analysis: One design goal is to maximize the laser detection percentage. The time that the laser is not being detected is the time in which the mechanism is moving from one position to another. By minimizing Tmotionwe will maximize the laser detection percentage. First we will calculate the motor characteristics at 9 Volts: We know that the linkage will have to move at most 38.25 degrees at the input link. We are going to assume a bang-bang controller because it is optimal for minimizing the time to move from one point to another. We assume that the motor will accelerate the linkage for half of the motion and decelerate it for the other half of the motion. For simplicity’s sake, we will assume that the motor works identically in acceleration and deceleration and that our inertia is roughly constant throughout the motion. To solve for the time it takes, we will solve the differential equation for the motion with the following initial conditions. When we solve that equation we get this equation for the position of the linkage:

- 21. 21 To find the total travel time we will find the time for it to reach half of the total travel distance and then double that time to account for deceleration. When we do that we get the following: We will then repeat that calculation for every combination of positions to find the time to go from any configuration to another. The following table shows the results of those calculations. Table 14.1: Computed theoretical travel time between positions Position 1 Position 2 Relative Angle (deg) Total Travel Time (sec) 1 2 11.25 0.076 1 3 24.83 0.114 1 4 38.25 0.142 2 3 13.58 0.084 2 4 27.00 0.119 3 4 13.42 0.083 We can find our best case predicted detection percentage easily. If we assume that it is equally likely to go to any position from any other position, with the exception that we do not expect to get the same position two times in a row. This means that our expected average time to move from one position to another is the average of all the times. Our detection percentage is then simply the total time that the lasers are on, minus the average time times the number of bursts fired all divided by the total time the lasers are on. We can also find the power supplied using the expressions we derived. Power can be found as a function of angular velocity.

- 22. 22 We can then find the max power by taking a derivative, setting it equal to zero and using that angular velocity in the power expression. This is the highest power supplied to the linkage during operation. It will draw more electrical power during stall but that is based on coil resistance inside the motor. Section 15: Torque Transfer Analysis Torque is being transferred at the joint that connects the motor shaft to the gear and at the point where the gear and the input link are connected with an off-axis dowel pin. Torque transfer analysis is being performed in order to determine the stresses in the joints where torque is being transferred and whether or not the stresses will cause failure. Failure can be defined as the yielding or slipping of a material due to stress. If the output torque and resulting stresses on the joints are too high, the linkage is at risk of not performing as we designed it to. For the purposes of the torque transfer analysis for this project, we assume that the dynamic motion of the screw and pin in their respective holes is negligible, or that the holes are a close enough fit to minimize the effects of motion in the objects within them. We are neglecting friction, as the friction coefficient between steel and nylon is small enough to be negligible. We are also assuming that torque and force are uniformly distributed across the stress surfaces so that stress concentrations aren’t due to inconsistencies in the materials or manufacturing but rather the assembly of the joint, and so that in our calculations we can use the average force over the area.

- 23. 23 Fig 15.1 Cross section of motor joint connecting to gear Fig 15.2 Free body diagram of the motor shaft torque joint The most critical component of this joint is the set screw, which transmits the torque from the motor shaft to the metal insert that connects to the gear, and has a holding force, or resistance to slipping, that can be overcome by the shear stress imposed by the motor shaft. We first calculate the maximum shear stress on the interface of the motor shaft and the metal insert. We then calculate the average shear force across the surface of the set screw.

- 24. 24 In order to determine whether or not the set screw will slip, we have to calculate the holding force of the set screw and compare it to the shear force provided by the motor shaft. The holding force is greater than the shear force, so the set screw will most likely not slip over the shaft. However, with a safety factor of only 1.19, it might be necessary to increase the amount of set screws used in order to better protect against failure. Fig 15.3 Cross section of input joint connected to gear with dowel pin Fig 15.4 Free body diagrams of the off-axis pin joint Because the yield strength of nylon is much lower than that of steel or aluminum, we assume that failure will occur in the gear first and therefore will concentrate the stress calculations on the interface between the dowel pin and the bevel gear. We also assume that the normal forces from above and below the gear cancel and that there is no normal force upward on the dowel pin, as it is press fit into the hole. First, we calculate the force of the dowel pin on the inner face of the hole in the bevel gear using the torque provided by the gear and the distance from the center of the input link joint to the center of the dowel pin.

- 25. 25 We then use the resulting force to calculate the principal stress in the x direction on the gear by the pin. We assume that the maximum stress area is half of the surface area of the hole, as the force transmitted by the pin is in the direction of rotation tangent to the circle of motion and is applied to only one half of the hole. Using the von Mises yield criterion, we see that the resulting stress is less than that of the yield strength (45 MPa for Nylon 6/6) divided by a safety factor of 3. The joint is therefore not in danger of yielding. Section 16: Deflection Analysis Deflection analysis is being performed at the coupler joints of the input and the output. The deflection will be the highest at these two points because the weight of the coupler, mirror, and joints are concentrated at this location, due to the cantilevered design of the linkage. We need to perform deflection analysis to ensure that the links are able to reflect light from the lasers onto the target effectively. Too much deflection could cause the light to be reflected incorrectly. The sketch relations we did with the linkage initially assumed that the mirror was perpendicular to the mounting surface. If the links deflect too much, the mirror would be reflecting light at an angle we did not account for. We also want to make sure the links aren’t deflecting so much that the bottom of the joints drag along the floor of the arena. We also will perform stress analysis to ensure that the links do not yield under the given load. If this were to occur, the light would not reflect correctly and the links would be plastically deformed, which isn’t good for the structural integrity of the links.

- 26. 26 We assumed that the deflection could be accurately approximated by beam deflection due to a point load plus the beam deflection due to self-weight because both the links are cantilevered from a single joint. The mass of the coupler and mirror is split between each joint and the moment of inertia for each beam is assumed to be that of an ⅛inch thick solid beam with a safety factor of 1.5 to account for the cutouts in each link. We determined the maximum allowable deflection to be 0.16 inches (4.064 mm), which is the distance between the bottom of the coupler and the ground. This was done as a static analysis because the only dynamic movement is horizontal. Our links are 6.4 times thicker horizontally, which results in a much greater second moment of inertia and stiffness. This horizontal movement also does not create an appreciable force vertically. The equations we used were: for point load deflection and for self-weight deflectionδ = 3EI Pl 3 δ = 8EI Pl 3 (assuming it is a point load concentrated at the center of mass of the beam). Figure 16.1 Free Body Diagram for the Input Link Figure 16.2 Free Body Diagram for the Output Link

- 27. 27 Point Load Deflection Calculations: Massat each joint was (in grams): 2*0.41 (2 needle bearings) + 6.41 (Shoulder Screw) + 14.48/2 (Half of the coupler) + 20 (Mirror) +2.72 (Nut)= 37.19 grams or 0.03719 kg Force ( )is then = 0.03719*9.81= 0.365 NP2 gF = m Length (L)= 5.62 inches (0.143 meters)(input) and 4.86 inches (0.123 meters)(output) Young’s Modulus (E)is 69 GPa. Second Moment of Inertia (I)= = (0.8*0.125^3)/12= 0.00104 in^4 (4.336*10^-10m^4)12 bh3 Plugging into the equation for point load deflection: Deflection Input: 0.0283 mm Deflection Output: 0.018 mm Self-Weight Deflection Calculations: Mass is 19.28 grams (0.01928 kg)for the input link and 16.2 grams (0.0162 kg)for the output link. Force = 0.01928*9.81= 0.189Nfor the input and 0.0162*9.81=0.159Nfor the output link.P1 P3 = All other parameters are the same as the point load deflection calculations: Deflection Input: 0.00231 mm Deflection Output: 0.00124 mm By the principle of superposition, the total deflection will be the sum of both deflections: Total Deflection Input: 0.0306 mm Total Deflection Output: 0.0192 mm Multiplying by our safety factor (1.5) due to the assumptions we made, we end up with: Total Deflection Input: 0.0459 mm Total Deflection Output: 0.0288 mm The safety factor against deflection is therefore 88.54 for the input and 141.11 for the output, which indicates the deflection is very far below the maximum deflection.

- 28. 28 Maximum stressis at the baseplate joint on both links, due to the assumption we made that the link is analogous to a cantilevered beam. Failure is defined as yielding of the aluminum. The equation being used is , where y is the distance to the centroidal axis of the cross-sectionalσ = I My area and I is the second moment of inertia. First we calculated the moment at the baseplate joint on each link − M i − 2 L * P1 − L * P2 = 0 Figure 16.3 FBD for Stress Analysis of Input Link − Mo − 2 L * P3 − L * P2 = 0 Figure 16.4 FBD for Stress Analysis of the Output Link We know y is half of its thickness (⅛inch): 1/16 inch (0.0015875 meters), and we already have the second moment of inertia of the beam from the deflection analysis, so we can take all the information and plug it into the stress equation: Max stress for the output: 0.241 MPa Max stress for the input: 0.200 MPa Multiplying by our safety factor: Max stress for the output: 0.313 MPa Max stress for the input: 0.260 MPa YIeld strength is 24 MPa(from the MMPDS database), so we have a safety factor of 99.6 and 120 respectively.

- 29. 29 Due to the very large safety factor on both links, we can say neither of the links will fail. Section 17: Safety & Motor Controls Introduction In general, motor controls are needed at the most basic level to turn the motor on and off depending on a given power supply. More specifically, if it is to be operated in a certain manner different from just turning it off and on, controls are needed to ensure that it operates in the desired manner. The safety portion of this comes into play as well because if something goes wrong while the motor is operating, it is good to have something that can automatically shut off the motor when the undesired event is occurring. These safety features ensure that the motor does not operate beyond the given bounds, as injury to the others may occur if that happens. The quality of controls is important as well, as error in the manufacture of the disk in the encoder can cause it to register that it is in a different location than it is actually in, causing the code that to stop working properly. Quality of controls can also affect whether the measurements of distance between objects and velocities are correct, which would interfere with the proper functioning of the IR sensor or motor encoder, as it wouldn’t sense how close it is to the hard stop, which would also prevent the motor encoder from telling the motor to slow down or stop. In this project, we will be using an Infrared sensor, Arduino microcontroller, limit switches, an H-bridge motor driver, and a motor controller. Section 18: Capabilities & Limitations of Sensors The infrared proximity sensor is an analog sensor that functions by outputting infrared light that reflects off of the object back onto the proximity sensor and outputs a certain voltage depending on the proximity of the object to the sensor. It can determine the presence of an object in close range, and within the scope of the project it can determine whether there are obstructions that would interfere with the functioning of the linkage. This sensor is limited by its range of measurement in that the limit of the input defines the largest distance at which the object can be placed so that it can still be detected. It is also limited in the angle at which the object can be with respect to the sensor, as the infrared light will not be able to detect an object placed in certain directions, even within the limits of the maximum distance. The limit switches are digital sensors that function by outputting a signal if enough force is applied to the switch, determined by whether or not the switch “clicks”. Because they require a certain amount of force in order to output a signal, the sensors are limited in their resolution, as an object may be present but applying a force smaller than the minimum force required to produce a reaction. Noise disturbs the sensor signal, reducing the precision of the readings. In terms of this project, this could mean that the sensors incorrectly detect the presence of an object or output the incorrect signal as a result of interference. The sensitivity limits the conversion of the input signal to the output signal, so depending on the sensitivity of the sensors, the output signal may or may not change with small changes in input. This can affect the function of the linkage in that sensors that are too sensitive or not sensitive enough may output incorrect signals that will prevent the linkage from functioning as it was designed to.

- 30. 30 Sensor 19: Mounting Considerations & Methods We tried to conserve volume as much as possible while placing the limit switches as far up as possible from the ground pivot to minimize the change in angle required to activate the switches. Figure 19.1 Limit Switch and IR Sensor Mounts We placed the IR mount so that it had a full view of the pinch points that might cause problems in the operation of the linkage. We slotted the mounts to allow for easy adjustment and used screws for rigid attachment to the baseplate. This reduces the possibility of movement of the limit switches over the course of operation.

- 31. 31 Figure 19.2 Mounts for Limit Switches and IR Sensor Mount Sensor mounting can increase the volume of the mechanism if placed beyond the bounds of the original mechanism or, in the case of the IR mount, machined to a height greater than that of the mechanism. The accuracy can be affected as a result of the variability in the change in angle needed to activate the switch. However, because the limit switches are mounted close to the ground pivots, the deceleration of the linkage upon approaching the limit switches doesn’t have to be as slow because the linkage would have to move through a larger angle to be in danger of overshooting and damaging the switch. Our method of sliding screws into slots into the mounts and then screwing the mounts into the baseplate would be acceptable in industry because we allowed for adjustability while maintaining a rigid attachment to the baseplate. The IR mount is a safe design because it looks over the most critical areas of the linkage that would, if obstructed, cause injury or damage to the mechanism. Section 20: Encoder Counts, IR Sensor Threshold, and Controller Gains We calculated what the theoretical encoder values would be using the encoder resolution and the angles from CAD. We found out encoder resolution using the following formula: Then we found the encoder value by taking each positions angle and dividing it by the resolution. This will give us the number of counts to each position from the zero point. One position’s calculation can be seen below, while the rest of the calculations can be seen in Table 20.1. In order to find the IR sensor threshold value we used measurements taken from the linkage. We calculated a safe distance, or the distance at which the linkage will never hit an object positioned at that location, for the IR sensor. We added an extra inch to our minimum safe distance to account for sensor noise, resulting in a safe distance of 8 inches. We then used the equation given by the manufacturer to find what the voltage reading would be for that distance. We converted that from voltage to an integer value because the Arduino library reads analog input as 0 when 0V and 1023 when 5v.

- 32. 32 Figure 20.1 IR Sensor Characterization We started with these calculated values and varied them until we achieved the best performance we could. The difference between the calculated values and the values that we are using are likely due to inaccuracies between the CAD model of the linkage. One likely source of error could be the thickness of the glue that holds the mirror to the coupler. The final Arduino code used during testing can be found in Appendix D and a summary of the variable and values assigned can be found below in Table 20.1: Table 20.1: Summary of Variables in Arduino Code Variable Name in Arduino Sketch File Purpose of Variable Device Calculated Value Actual Value Used During Testing DESPOSITION1 Laser Position #1 Motor 0 28 DESPOSITION2 Laser Position #2 Motor 38 86

- 33. 33 DESPOSITION3 Laser Position #3 Motor 83 165 DESPOSITION4 Laser Position #4 Motor 127 251 LOWER_BOUND Motor Calibration Motor 0 0 UPPER_BOUND Motor Calibration Motor 127 262 proxSwitchThreshold Threshold value for proximity sensor before stopping the motor Proximity Sensor 211 220 Kp Proportional Gain Motor Not Calculated 0.600 Ki Integral Gain Motor Not Calculated 0.030 Kd Derivative Term Motor Not Calculated 0.004 BASE_CMD Base voltage to make motor just rotate Motor Not Calculated 3.225 CTRL_DEAD_BAND Range of encoder counts where voltage is not sent to motor Motor 4 1 SUPPLY_VOLTAGE Supply voltage at H-bridge H-bridge 9 9.00 Section 21: Arduino Code Changes We made a few important changes to the code for our linkage. The first is that we added a section to zero out our linkage at the start of code execution. We did this by adding the following to the end of the void setup method. What this code does is set the voltage to (9V)(230/256) in the backwards direction until the left limit switch is hit. Once the limit switch is hit, it turns the power to 0V and tells the encoder that it is zeroed. Since this is in the void setup, it will run only once when the Arduino is restarted or power cycled.

- 34. 34 Additionally we made a change to the way the base voltage works in the PID Controller function. To account for the slop in the gear train we added a spring to the linkage. This worked great for the mechanical systems but it hurt the controllers ability to react. We decided to account for that by having bidirectional base voltages as you can see below. This was changed because we wanted the final value we add to it to be approximately enough to overcome the spring. The PID itself could account for it, but it would be slower than if we tailor it directly. The left acting value is much larger because it needs to fight against the spring to start to move. Strictly speaking, these values should be a function of linkage position, but we decided it wasn’t a good use of time to determine the exact function for our controller. The linkage worked much better with these constants and we thought that was an acceptable middle ground. The final change we made was to comment out all of the serial.write commands that run every loop execution inside of the void loop method. This makes the loop run faster and thus have smoother control and/or allow us to use a more aggressive PID tuning. Section 22: Final Testing Results In order to set up for final testing we slid the dowel pins and secured the bolts in the baseplate into their respective holes in the arena. We connected the fuse holder between the positive terminal on the power supply and positive terminal on the H-bridge. In order to upload the code onto the Arduino, we connected it to its USB port and into the computer. We connected the four leads, which control the on and off positions of each of the four lasers into their respective jumpers for the laser command wires. For final testing, after the initial position was set and the linkage calibrated, the mechanism was subjected to a standardized test consisting of 40 laser beams shot from lanes 1-4 in a randomized order. The first 20 signals lasted for 4 seconds each and the final 20 signals lasted for 2 seconds each. This was done over three trials, the best of which would ultimately be selected for grading, with 2 minutes in between each trial to allow for adjustments. The total volume was measured by setting the linkage to its starting position and measuring the length, height, and width using a meter scale. The transmission angle offset, or the largest absolute value of the transmission angle of the mechanism minus the ideal transmission angle of 90 degrees, was measured in each linkage position from the coupler to the follower with a machinist’s protractor. The percentage of the 40 laser signals that the mirror is able to reflect onto the target and have detected by the sensor, or the reflection accuracy, was tested by counting the total number of detections from Labview and dividing the resulting

- 35. 35 number by 40. The process for testing the laser detection percentage involved counting the total detection time from Labview and dividing the resulting number by the total test time. The steady state error, or the average distance from the center of the reflected beam to the center of the target, was measured using a meter scale from center to center. Total Volume: 120 cm x 155 cm x 55 cm Table 22.1: Transmission Angle Data Max Min Transmission Angle 110° 60° Table 22.2: Final Testing Results Trial Reflection Accuracy Laser Detection Percentage 1 53% 40/40 2 45% 40/40 3 63% 40/40 Table 22.3: Steady State Error in # of Concentric Rings Outside of the Target Position 1 to 2 2 to 3 3 to 4 4 to 1 Steady State Error 0 ring(s) 0 ring(s) 0 ring(s) 0 ring(s) We expected the linkage positions to be much more accurate than they ended up being. Following tuning for our final design including the extension spring, we tested the accuracy of the linkage and found the laser to be on target in most cases excluding the transition from Position 4 to Position 1, but as we didn’t have enough time before final testing to further manipulate the linkage, encoder counts, and constant values, we decided to let it be. Ultimately, during final testing we found that the positions were initially accurate but became less accurate over the course of each trial because, as predicted from previous tests, the encoder counts were not able to reset in the transition from Position 4 to Position 1, most likely because the linkage needs to both hit the limit switch and be at zero velocity in order for the values to be reset and the extension spring accelerated the linkage in the opposite direction too fast to account for a loop iteration at zero velocity. Section 23: Design Critique & Evaluation 1. What worked well? What didn’t work well? Most importantly, explain why.

- 36. 36 a. In our final design we had a very compact linkage that minimized volume and had a limited transmission angle deviation. The links were easily manufactured out of ⅛” aluminum which provided a small moment of inertia while maintaining high stiffness and machinability. The use of an rubber hard stop inside of the two links made it possible for us to conserve space on the whole mechanism and reduced damage to the link when impacting the hard stop. Most notably, we added a spring to the mechanism. This addition was made to pull the linkage to one side of the natural mechanical error that was due to slop in the transmission. This spring made our linkages position more consistent but it slowed the motor as the spring was being extended and made the motion very violent as the spring was being relaxed. We also used bevel gears in our design, which greatly conserved volume, but introduced a considerable amount of slop. The bevel gears also had to be altered using creative methods from the difficult manufacturing challenges. We also used oil impregnated nylon as our coupler, which highly reduced the inertia of the linkage, however, as it was machined the nylon slightly altered shape and was not perfectly square after machining was completed. We were able to account for this in the mirror mounting and the linkage positions. 2. How well did your design perform relative to your models? Explain what you think the difference was. a. Our model of our linkage without a spring predicted a much higher resolutions than we were actually able to achieve. We attribute this to slop between the linkage and the encoder. This slop comes from both the internal gearbox and out bevel gear. We could adjust how the bevel gears mesh to reduce that slop greatly, but there wasn’t anything we could do to adjust the internal gearing. The dynamic models of our linkage were quite accurate when we didn’t have the spring added. Once we added the spring our models became a poor representation of the linkage. The model wasn’t too bad when the spring is mostly relaxed around positions 3 and 4. It started to deviate majorly around positions 1 and 2. 3. How did friction influence your built device? a. The friction was greater than anticipated originally because of the fact that the steel roller bearings produced grooves in the aluminum spacers. The the bronze sleeve bearings were machined to fit the ⅛” aluminum, which made the sleeve bearing slightly less effective. This introduced friction was constant through the motion of the links and was accounted for using a base command voltage to overcome any intrinsic friction in the system before control voltages were applied. 4. How could the control algorithm (Arduino code) be improved to make better use of the available equipment? For example, could the position be more precisely controlled? Could you make use of a feed-forward signal? How?

- 37. 37 a. We approximated the force exerted by the spring as constant, which in reality it is not constant, so we could have characterized the spring force and set a voltage that matched the spring force at any given position, similar to the base command voltage for the frictional force. We could combine the spring force with the frictional force in a linear function of position. We would find the voltage required to make the linkage start to move near each limit switch in each direction. We will then idealize our spring as an ideal torsional spring that is proportional to the angle of the linkage with a preload. By using a different equation for forward motion and for reverse motion we would account for the dry friction inside of the spring expression. 5. Would there be a better way to use the sensors that were provided, or to use different sensors, to accomplish the same objectives? a. We could have set a high resolution encoder directly attached to the linkage, which wouldn't have been affected by the mechanical slop contained in the transmission and the motor. The limit switches had a slight range in which they activated and and reset the encoder value. We could have moved the limit switch outward so that the link would just barely trip the limit switch, that way the positions caught by the limit switches were the most accurate as possible. This same accuracy could have been achieved by moving the limit switches further away from the link pivot, so that the range of activation in the limit switch would correspond to a smaller change in angle at the ground pivot of the links. 6. What other lessons or unique observations did you make about your device and the process that you follow to develop it? Having completed it, would you do anything different – what and why? a. We realized soon into the design that little issues pop up and that the CAD model does not translate perfectly into manufacturing. This produces the necessity for an iterative design. We also learned that there is always slop in transmission, so finding a method to account for this slop is important to the accuracy of the final design. Another thing that we noticed was the delay encountered by the code due to the comments in the serial monitor. we experienced considerable increases in speed when we commented out anything that wrote text to the screen. If we could go back and do anything differently, we would have added a spring sooner and spent more time working out the kinks introduced by adding the spring. 7. On a scale of 1-5, how would you rate the safety of your mechanism? Were the provided sensors adequate or would additional sensors and guards be necessary? a. 4, we had an IR sensor that looked over the pinch points of our mechanism as well as over the range of motion of the coupler. The IR sensor had some problems with covering the end of the linkage, so an additional IR sensor to fully cover the entirety of the linkage may have helped to improve safety. Also, if something were to get too close to the gears it would have been possible to get caught in the gear teeth. By covering the transmission we would have improved safety of the design.

- 38. 38 8. Would you recommend that we give your device to someone else right now to use and operate? Why or why not? a. We would recommend giving this device to be used by somebody else. The design is simple and easy to use with an acceptable degree of safety. The manufacturing is robust and not at risk of being easily damaged. The device performs well and has very low steady state error so there would be no need for additional tuning. 9. What other parts and materials would have been useful to have in your design, if you had been given them? a. We would have found a sheet of ⅛” aluminum as well as a variety of set screws useful, both of these components we purchased ourselves and would be commonly used in designs for future classes. 10. What would you do for a project next year in ME350? a. The project would be a printer that can feed paper and manipulate a pen in order to write a cursive phrase. This phrase can be changed for the day of the competition. The device would be graded on the speed that it can produce the phrase, volume of the printer and the accuracy of the phrase to a template produced before the competition. Overall, this project introduced a the design challenge of controlling the links through the use of code and an encoder. Because the device could not be remotely controlled, it forced our design to be much more precise, as slop could not be accounted for in real time through remote control. This sensitivity to error was amplified by the distance that the laser had to travel over the entirety of testing. Overall this project put an emphasis of precision in every aspect of the design.

- 39. 39 Appendix A: Individual Sketch Relations Design, 3D Solidworks, and ADAMS Analysis In terms of the mechanism synthesis we did on Solidworks, it was done so we could get a basic idea of how long our links would be and where the ground pivots would be while still reflecting the light onto the target. To do this, we created a four bar linkage that had the midpoint of the coupler constrained to one of the lanes. Then, to mimic the angle of incidence of the light being equal to the angle of reflection, we bisected a line connected to the corresponding lane from the target and drew a perpendicular line from the center of the coupler to the center of the target. We then repeated this for the other three lanes and were able to synthesize link lengths from this. Solidworks allowed us to make a 3D model of the linkage to ensure that there would be no interferences between links as it went through its full range of motion. In addition, the thicknesses could’ve also had an impact on the transmission angles, so the 3D modeling allowed us to ensure that issue could be remedied. ADAMS allowed us to import our 3D linkages and test to make sure the geometry of the linkage allowed us to move quick enough through our entire range of motion without using too much power. In order to do this, we had to create joints between each link and put a motion on the input to simulate the motion of the linkage. Afterwards, we viewed the results graphs and checked to make sure they fit our criteria. Ted’s Design-Solidworks Sketch This design had an input link of 9.2 inches and output of 8.6 inches, as well as being mounted on the right side of the mounting holes on the table. This was done to minimize the transmission angle deviation as well as to maintain a transmission angle as close to 90 degrees for all four positions as possible. Table A.1: Link Lengths for Ted’s Design Input Length Output Length Coupler Length 9.3 inches 8.6 inches 2 inches Table A.2: Transmission Angles and Deviations for Ted’s Design Transmission Angle Transmission Angle Deviation Lane 1 101.13 11.13 Lane 2 87.11 2.89 Lane 3 74.15 15.85 Lane 4 61.58 28.42

- 40. 40 Figure A.1: Solidworks sketch of Lane 1 and Lane 2 for Ted’s Design Figure A.2 Solidworks sketch of Lane 3 and Lane 4 for Ted’s Design

- 41. 41 Travis’ Design-Solidworks Sketch The transmission angles are averaged around 90 to minimize the transmission angle deviation. The links were intentionally made long to minimize the transmission angle deviation and to minimize the amount of rotation that had to happen at the ground pivot so that translational movement at the coupler could happen faster for each unit of rotation at the ground pivot the follower link was made shorter than the input link to reduce the rotational inertia of the system in order to minimize torque needed to accelerate the links through their motion. The mounts to the table are also concentric with dowel holes in the table. Table A.3 Link Lengths for Travis’ Design Input Length Output Length Coupler Length 10.83 inches 8.56 inches 2 inches Table A.4: Transmission Angles and Deviations for Travis’ Design Transmission Angle Transmission Angle Deviation Lane 1 100.98 10.98 Lane 2 84.33 5.66 Lane 3 70.37 19.63 Lane 4 58.19 31.81 Figure A.3: Transmission Angles for Travis’ Design

- 42. 42 Figure A.4 Link Lengths of Travis’ Design Anna’s Design-Solidworks Sketch I designed the links to be short so that there would be less end deflection. I made the coupler 2.2 inches long both to more accurately represent the placement and size of the mirror and so that the input and output links would be more proportionate. The ground pivots are placed to the right of the lanes because it allowed for the greatest accuracy in the deflection of the laser off of the coupler so that it would hit the target. However, due to the placement of the ground pivots, my transmission angle deviations are longer than those of the other designs. Table A.5 Link Lengths for Anna’s Design Input Length Output Length Coupler Length 9.76 inches 7.52 inches 2 inches Table A.6 Transmission Angles and Deviations for Anna’s Design Transmission Angle Transmission Angle Deviation Lane 1 120.3 30.3 Lane 2 92.98 2.98 Lane 3 74.82 15.18 Lane 4 60.69 29.31

- 43. 43 Figure A.5 Transmission Angles for Anna’s Design Figure A.6 Link Lengths for Anna’s Design Kevin’s Design-Solidworks Sketch The links are both longer than any of the other designs on our team. This was done because the mirror wouldn’t need to be moved very far in order to align it with the laser. The mounts are also relatively far away from the actual mounting holes, so it would require a larger platform. Table A.7 Link Lengths for Kevin’s Design Input Length Output Length Coupler Length 16.32 inches 11.96 inches 2 inches Table A.8 Transmission Angles and Deviations for Kevin’s Design Transmission Angle Transmission Angle Deviation Lane 1 114 24

- 44. 44 Lane 2 94.76 4.76 Lane 3 80.84 -9.16 Lane 4 70 -20 Figure A.7 Transmission Angles for Kevin’s Design Figure A.8 Link Lengths for Kevin’s Design

- 45. 45 Ted’s Design-Solidworks Model The design is mounted near the right side of the mounting holes, but they aren’t actually concentric to the mounting holes themselves. Each link is one inch wide and a quarter-inch thick to provide enough stiffness to this cantilevered design. The coupler is also on top of the links to provide flexibility in mounting height. Figure A.9 Full Range of Motion for Ted’s Design Figure A.10 Isometric view of Ted’s Design

- 46. 46 Travis’ Design-Solidworks Model The initial design utilized the dowel holes in the playing field to ensure smooth and precise rotation. This imposes limitations on where your mounting points can be located and resulted in longer links than had originally been designed. Each link was also an inch wide to provide stiffness when rotating. Figure A.11 Full range of motion and Isometric view of Travis’ Design Anna’s Design-Solidworks Model The linkage had to be moved slightly to be put in a realistic mounting area near the middle of the mounting holes. Additionally, the pivot points are closer together than all of the other designs on the team to keep transmission angle as close to 90 degrees as possible.

- 47. 47 Figure A.12 Full range of motion and Isometric view of Anna’s Design Kevin’s Design-Solidworks Model I was able to significantly shorten the links by changing the constraint on the sketch so the coupler could reflect light off the entirety of the mirror as opposed to just the center, which lowers the moment of inertia significantly. My design is also mounted off center from the middle of the mounting holes and will require a platform.

- 48. 48 Figure A.13 Full range of motion for Kevin’s Design FIgure A.14 Isometric view of Kevin’s Design

- 49. 49 Ted’s Design-ADAMS Model The angular position and velocity profile fit the requirements of a rapid acceleration and deceleration. The power consumption increases steadily until the point of deceleration then decreases sharply. The torque needed follows a similar profile to the power consumption. The values for the torque are all under 1 watt, so the motors can all power it. Figure A.15 ADAMS model of Ted’s Design Figure A.16 Angular Displacement and Velocity of Ted’s Design

- 50. 50 Figure A.17 Power Consumption and Input Torque required for Ted’s Design Travis’ Design-ADAMS Model The ADAMS Model for this design showed the expected values for velocity and torque yet had a more choppy graph for power. This can likely be explained by the overlap in the links part way through the simulation or by the inclusion of friction as the two links begin to overlap. This overlap is due to the duration of 1 second, which is longer than the link will actually take to travel during its actual motion. The power consumption is also significantly less than 1 watt. Figure A.18 ADAMs model of Travis’ Design

- 51. 51 Figure A.19 Velocity, Power consumption, and input torque for Travis’ Design Anna’s Design-ADAMS Model The angular displacement and velocity graph were both similar to the other designs but the power consumption was very high at almost 1 Watt, likely due to the length of the links. The torque was also pretty high, but the length of the cantilevered links likely increased torque necessary to move the links. Figure A.20 ADAMS model of Anna’s Design

- 52. 52 Figure A.21 Angular position and velocity for Anna’s Design Figure A.22 Power consumption and input torque for Anna’s Design Kevin’s Design-ADAMS Model The max power consumption was lower than all the rest of the designs due to the relatively short lengths of the links themselves. Correspondingly, the torque was also very low. This design was definitely the most efficient in terms of power consumption and torque needed.

- 53. 53 Figure A.23 ADAMS model of Kevin’s Design Figure A.24 Angular Position and Velocity of Kevin’s Design

- 54. 54 Figure A.25 Power Consumption and Input Torque for Kevin’s Design

- 55. 55 Appendix B: Drawings, Manufacturing Plans, Bill of Materials, and Assembly Plan for Final Design Bill of Materials Part Name Quantity Supplier Part Number Price Aluminum Plate, 1/4" x 12" x 18" 1 McMaster-Carr 9246K45 Kit of Parts SAE 841 Sleeve Bearing for 1/4" Shaft Diameter, 1/4" Length 2 McMaster-Carr 6391K126 Kit of Parts Needle Thrust Bearing, Bore .250 4 Grainger 4XFL8 Kit of Parts Mirror – 25.4 mm x 51 mm x 6 mm 1 Edmund Optics 27453 Kit of Parts Shoulder Bolts 4 McMaster-Carr 91259A537 From Available Parts Nuts, 3/8-16 2 McMaster-Carr 97149A200 From Available Parts 1/4" ground and polished steel dowel pins 2 McMaster-Carr Kit of Parts Aluminum Plate, 1/8” x 6” x 24” 1 McMaster-Carr 8975K921 12.81 MDS-Filled Cast Nylon Rectangular Bar 1” x 1” x 12” 1 McMaster-Carr 2882K41 14.95 Neoprene Spring Rubber Tube, 3/4" OD, 1/4" ID, 6" Long, 75A Durometer 1 McMaster-Carr 8637K111 2.87 Aluminum round stock, 1in Diameter, 6in Long 1 McMaster-Carr 8974K133 Kit of Parts Total: $30.63

- 56. 56 Assembly Manual Baseplate 1. Press fit dowel pins (2) into the baseplate (1) 2. Insert socket head cap screws (3) into designated holes on baseplate 3. Align small hard stop spacer (7), hard stop (4), and large hard stop spacer (5) over appropriate hole. Insert shoulder screw (6) and thread into baseplate

- 57. 57 Linkage 4. Press fit bronze bushings (8) into holes on input (9) and follower (10) links

- 58. 58 5. Align needle thrust bearings (11) and washers (12) over holes on input and follower 6. Align holes on coupler link (13) over appropriate holes on input and follower links

- 59. 59 7. Secure needle thrust bearings (11) over holes on top of the coupler. 8. Align the holes and place aluminum spacers (14) over needle thrust bearings (11).

- 60. 60 9. Insert shoulder screws (15) into the holes and secure with locknuts (16) on ends 10. First align the cut 1.25 inch gear (18) over the input (9) joint and pin it with the 1/16” dowel pin (17). Then align the needle thrust bearings (11), small aluminum spacers (14), and large aluminum spacers (5) over the top and bottom of the input (9) and output (10) joints. Bolt the input joint together with the 1 inch shoulder screw (17) and the output joint with the ½ inch shoulder screw (15)

- 61. 61 11. Fasten linkages to the threaded holes in baseplate using the shoulder cap screws 12. Attach full assembly to appropriate holes in the arena.

- 62. 62 Appendix C: Approval Packages, Bill of Materials, and Assembly Plan for Transmission Design Approval Packages: Motor Bracket

- 63. 63 Raw Material Stock: 2” by 2.5” angle stock, ¼” thickness Step # Process Description Machine Fixtures Tool(s) Speed RPM 1 Cut the stock to approximately 2.55” Bandsaw 2 Clamp the piece into the vise Mill Vise Parallels 3 Face the bandsawed edge enough to get a smooth face taking at most 0.050” passes Mill Vise 3/8” endmill, 3/8” collet 1000 RPM 4 Flip the part and face to the final length Mill Vise 3/8” endmill, 3/8” collet 1000 RPM 5 Mark out and cut the cutout on the bandsaw leaving 0.05” to 0.10” of material left Bandsaw 6 Clamp the piece in the vice with the cutout facing up Mill Vise 7 Mill the cutout to the final size Mill Vise 3/8” endmill, 3/8” collet 1000 RPM 8 Clamp the piece in the vise with the edge with the cutout flat Mill Vise 9 Zero the read out to the lower left corner of the part Mill Vise Drill chuck, edge finder 1000 RPM 10 With a center drill Mill Vise Drill Chuck, 1000 RPM

- 64. 64 then a # 7 drill bit, drill the 6 extreme ends of the slots center drill, #7 drill bit 11 With a 3/16” endmill follow 0.030” inside the outer profile of the slot, taking a 0.050” depth cut each time Mill Vise 3/16” endmill, matching collet 1500 12 Conventional cut the entire profile of the slot to .005” of the final size Mill Vise 3/16” endmill, matching collet 1500 13 Cliff cut the profile to the final size Mill Vise 3/16” endmill, matching collet 1500 14 Repeat 11-13 for the other two slots Mill Vise 3/16” endmill, matching collet 1500 15 Flip the part so the motor hole pattern face is facing up. Mill Vise 16 Zero the read out to the lower left corner Mill Vise 17 Center drill, then drill with a #30 drill bit all the A holes Mill Vise Drill Chuck, center drill, #30 drill bit 1000 RPM 18 Center drill, then drill with a ½” drill bit the B hole Mill Vise Drill Chuck, center drill, ½” drill bit 800 RPM 19 Deburr the holes and all edges Mill Vise File, deburring tool 20 Plunge both ends of the small slots with a Mill Vise ⅛” end mill, collet 1500

- 65. 65 ⅛” end mill and connect them 21 Plunge the other end of the center hole slot with a ½” end mill and connect them smoothly Mill Vise ½” end mill, collet 1000 Gear Insert Raw Material Stock: 2 inch long ¾ “ Aluminum Round Stock Step # Process Description Machine Fixtures Tool(s) Speed (RPM) 1 Turn 0.95” of the stock to 0.7” Lathe 1000 2 Center drill then drill a hole to a depth of 0.420” Lathe Center drill, C drillbit 1000 3 Turn the stock to 0.375” a depth of Lathe 1000

- 66. 66 0.560” starting at a depth of 0.25” 4 Part the piece Lathe Parting tool 200 5 Deburr the hole and the piece File 6 Clamp the piece onto the mill on the circular faces and edge find the piece Mill Vise Drill chuck, edge finder 7 Center drill and drill each hole Mill Vise Drill chuck, Center drill, 43 drillbit, 29 drillbit 1000 8 Tap each hole Vise Drill chuck, Dead center, tap drill, #440 tap, #832 tap

- 67. 67 Baseplate

- 70. 70

- 72. 72 Hard Stop

- 74. 74 Hard Stop Top Spacer

- 75. 75 Input Link

- 77. 77

- 78. 78

- 79. 79 Limit Switch Mount A

- 80. 80 Limit Switch Mount B

- 81. 81

- 82. 82 Output Link

- 84. 84 Bill of Materials: Part Name Quantity Supplier Part Number Price 20 degree Pressure Angle Nylon Mitre Gears 2 McMaster-Carr 729K15 $10.78 29:1 Metal Gearmotor 37Dx52L mm with 64 CPR Encoder 1 Pololu 1442 Kit of Parts Aluminum Angle Stock, 2.5" x 2" x 1/4" 1 McMaster-Carr Custom Kit of Parts Aluminum round stock, 1in Diameter, 6in Long 1 McMaster-Carr 8974K133 Kit of Parts 1/16" ground and polished steel dowel pins 2 McMaster-Carr Kit of Parts #4-40 screw 1 McMaster-Carr Kit of Parts M3 screws 6 Pololu Kit of Parts #8-32 set screws 25 McMaster Carr 92313A191 $3.00 2.5” Extension spring 1 McMaster-Carr 9654K53 Assembly Room Total: $13.78

- 85. 85 Assembly Manual Baseplate 1. Press fit dowel pins (2) into the baseplate (1) . 2. Insert socket head cap screws (3) into designated holes on baseplate

- 86. 86 3. Align small hard stop spacer (7), hard stop (4), and large hard stop spacer (5) over appropriate hole. Insert shoulder screw (6) and thread into baseplate Linkage 4. Press fit bronze bushings (8) into holes on input (9) and follower (10) links 5. Align needle thrust bearings (11) and washers (12) over holes on input and follower

- 87. 87 6. Align holes on coupler link (13) over appropriate holes on input and follower links. 7. Secure needle thrust bearings (11) over holes on top of the coupler.

- 88. 88 8. Align the holes and place aluminum spacers (14) over needle thrust bearings (11). 9. Insert shoulder screws (15) into the holes and secure with locknuts (16) on ends.

- 89. 89 10. First align the cut 1.25 inch gear (18) over the input (9) joint and pin it with the 1/16” dowel pin (17). Then align the needle thrust bearings (11), small aluminum spacers (14), and large aluminum spacers (5) over the top and bottom of the input (9) and output (10) joints. Bolt the input joint together with the 1 inch shoulder screw (17) and the output joint with the ½ inch shoulder screw (15). 11. Fasten linkages to the threaded holes in baseplate using the shoulder cap screws

- 90. 90 Motor 12. Align the 1.25 inch gear (20), gear insert (21), motor bracket (22), and motor (23) together 13. Insert the #4-40 screw (24) and the set screw (25) into the motor assembly 14. Fasten the motor to the baseplate

- 91. 91 15. Fasten the linkage to the field using the dowel pins and the cap screw

- 92. 92 Appendix D: Wiring Diagram, Arduino Code, Calculations, and Bill of Materials for Safety & Motor Controls Wiring Diagram:

- 93. 93 Arduino Code:

- 94. 94

- 95. 95

- 96. 96

- 97. 97

- 98. 98

- 99. 99 Calculations:First, we found the degrees per count, where Nis defined as gear ratio, n is counts per revolution, 4 is for quadrature, and 360 is a full revolution: Now, we found the encoder count at positions two, three, and four by dividing the link’s angular position by the degrees per count: Bill of Materials: Part Name Quantity Supplier Part Number Price Arduino Uno microcontroller board 1 Sparkfun DEV-09950 Kit of Parts Snap Action Switch (a.k.a. limit switch, microswitch) 2 Jameco 187733 Kit of Parts Infrared Proximity Sensor, short range 1 Sparkfun GP2D120XJ00F Kit of Parts H-bridge (L298 Motor Driver -- preassembled) 1 Solarbotics K CMD Kit of Parts 400-point Breadboard 1 Pololu 351 Kit of Parts Toggle Switch Single Pole Single Throw (On-Off) 1 Jameco 76523 Kit of Parts Mounting Board for Arduino, H-bridge, and breadboard 1 N/A Custom Kit of Parts Total: $0.00