MEMC Electronic Materials Initiation of Coverage - $70 Target

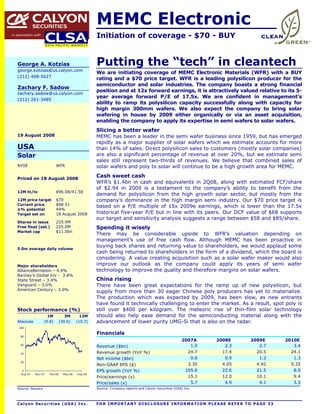

- 1. MEMC Electronic in association with Initiation of coverage - $70 - BUY TM George A. Kotzias Putting the “tech” in cleantech george.kotzias@us.calyon.com We are initiating coverage of MEMC Electronic Materials (WFR) with a BUY (212) 408-5627 rating and a $70 price target. WFR is a leading polysilicon producer for the semiconductor and solar industries. The company boasts a strong financial Zachary F. Sadow position and at 12x forward earnings, it is attractively valued relative to its 5- zachary.sadow@us.calyon.com year average forward P/E of 17.5x. We are confident in management’s (212) 261-3485 ability to ramp its polysilicon capacity successfully along with capacity for high margin 300mm wafers. We also expect the company to bring solar wafering in house by 2009 either organically or via an asset acquisition, enabling the company to apply its expertise in semi wafers to solar wafers. Slicing a better wafer 19 August 2008 MEMC has been a leader in the semi wafer business since 1959, but has emerged rapidly as a major supplier of solar wafers which we estimate accounts for more USA than 14% of sales. Direct polysilicon sales to customers (mostly solar companies) Solar are also a significant percentage of revenue at over 20%, but we estimate semi sales still represent two-thirds of revenues. We believe that combined sales of NYSE WFR solar wafers and poly to solar will continue to be a high growth area for MEMC. Priced on 18 August 2008 Cash sweet cash WFR’s $1.4bn in cash and equivalents in 2Q08, along with estimated FCF/share of $2.94 in 2009 is a testament to the company’s ability to benefit from the 12M hi/lo $96.08/41.58 demand for polysilicon from the high growth solar sector, but mostly from the 12M price target $70 company’s dominance in the high margin semi industry. Our $70 price target is Current price $48.51 based on a P/E multiple of 15x 2009e earnings, which is lower than the 17.5x ±% potential 44% Target set on 18 August 2008 historical five-year P/E but in line with its peers. Our DCF value of $68 supports our target and sensitivity analysis suggests a range between $58 and $85/share. Shares in issue 225.9M Free float (est.) 225.0M Spending it wisely Market cap $11.0bn There may be considerable upside to WFR’s valuation depending on management’s use of free cash flow. Although MEMC has been proactive in buying back shares and returning value to shareholders, we would applaud some 5.0m average daily volume cash being returned to shareholders in the form of a dividend, which the board is considering. A value creating acquisition such as a solar wafer maker would also Major shareholders improve our outlook as the company could apply its years of semi wafer AllianceBernstein – 4.9% technology to improve the quality and therefore margins on solar wafers. Barclay’s Global Inv - 3.8% State Street – 3.4% China rising Vanguard – 3.0% There have been great expectations for the ramp up of new polysilicon, but American Century – 3.0% supply from more than 30 eager Chinese poly producers has yet to materialize. The production which was expected by 2009, has been slow, as new entrants have found it technically challenging to enter the market. As a result, spot poly is Stock performance (%) still over $400 per kilogram. The meteoric rise of thin-film solar technology 1M 3M 12M should also help ease demand for the semiconducting material along with the Absolute (9.8) (30.6) (10.7) advancement of lower purity UMG-Si that is also on the radar. 100 Financials 80 2007A 2008E 2009E 2010E 60 Revenue ($bn) 1.9 2.3 2.7 3.4 40 Revenue growth (YoY %) 24.7 17.4 20.5 24.1 Net income ($bn) 0.8 0.9 1.2 1.3 20 Non-GAAP EPS ($) 3.30 4.05 4.92 5.32 0 EPS growth (YoY %) 105.6 22.6 21.5 8.0 Aug-07 Nov-07 Feb-08 May-08 Aug-08 Price/earnings (x) 15.1 12.0 10.1 9.4 Price/sales (x) 5.7 4.9 4.1 3.3 Source: Reuters Source: Company reports and Calyon Securities (USA) Inc. Calyon Securities (USA) Inc. FOR IMPORTANT DISCLOSURE INFORMATION PLEASE REFER TO PAGE 33

- 2. WFR - BUY Contents Slicing a better wafer .............................................................................. 3 Cash sweet cash ...................................................................................... 6 Spending it wisely ................................................................................. 12 China rising ........................................................................................... 20 Appendices............................................................................................ 24 All prices quoted herein are as at close of business 18 August 2008, unless otherwise stated. FOR IMPORTANT DISCLOSURE INFORMATION, PLEASE REFER TO PAGE 33 More research for your alternative-energy portfolio 2 george.kotzias@us.calyon.com 19 August 2008

- 3. Section 1: Slicing a better wafer WFR - BUY Slicing a better wafer MEMC has been a leader in the semi wafer business since 1959, but has emerged rapidly as a major supplier of solar wafers which we estimate accounts for more than 14% of sales. Direct polysilicon sales to customers (mostly solar companies) is also a significant percentage of revenue at over 20%, but we estimate IC sales still represent two-thirds of revenues. We believe that combined sales of solar wafers and poly to solar will continue to be a high growth area for MEMC. As an experienced tier 1 polysilicon producer, WFR has been able to increase market share due to economies of scale, industry know-how and top talent. The company has been at the helm of technological innovation and has led capacity expansion for four decades. We believe WFR is well positioned to capitalize on the extremely tight polysilicon market that should last through 2009. Premium poly player WFR benefits from WFR has benefited from being an experienced tier-1 polysilicon producer during experience and increased the early growth stage of the solar industry. As one in a small group of market share of established polysilicon producers, WFR has been able to build out its solar polysilicon to 14% in 2007 capabilities while capturing market share and positioning itself at the helm of technological innovation. In 2007 WFR had 14% market share of the polysilicon market, up from 12% and 13% in 2005 and 2006, respectively. Economies of scale and technological know-how have led WFR to this incumbent position. Figure 1 Polysilicon Market Share - 2007 Other 12% Hemlock 25% Mitsubishi 7% MEMC 14% Wacker 15% Tokuyama 13% REC 14% Source: Company reports and Calyon Securities (USA) Inc. estimates Sources of revenue WFR manufactures a MEMC is a large-scale manufacturer and designer of a variety of polysilicon variety of polysilicon products intended for the semi and solar industries. The company sells three products on a large scale categories of polysilicon wafers; Prime Wafers, Epitaxial Wafers and Test/ Monitor for solar and semi industries Wafers, that range from 100mm to 300mm. By year end 2008 WFR’s polysilicon capacity will have grown to 8,000MT and will have extended its global reach to encompass 2 poly and 7 wafer facilities in 6 different countries. 19 August 2008 george.kotzias@us.calyon.com 3

- 4. Section 1: Slicing a better wafer WFR - BUY Figure 2 Figure 3 Revenue by region – 2007 Revenue by segment - 2007 Polysilicon Europe 22% 15% U.S. Solar 24% Asia Pacific W afer Semi 61% 14% Wafer 64% Source: Company reports MEMC - silicon since 1959 Silicon since 1959 Since its founding in 1959, Missouri based MEMC Electronic has enjoyed a long and prosperous 50 year history partaking in the design, development and sale of its silicon wafers to the integrated circuit market and solar industry, encountering few impediments along the way. The well positioned silicon and wafer heavyweight finds itself strategically straddling the saturated $1 trillion integrated circuit market and the blooming $18 billion solar industry providing each with the necessary poly. Although the company has seen mostly success over the decades, along with the rest of the electronic/integrated circuit and semiconductor industries, MEMC faced major setbacks just before the turn of the century due to overcapacity and steep drop off in demand. Subsequent to surviving the turmoil, today they face a new challenge of meeting increasing demand for poly from solar. Brief history Defining industry MEMC established itself as a technological leader not long after its inception with standards much of its fundamental research coming about during the 1960’s. The research was so landmark that much of the work done at the time still remains an industry standard today such as the chemical-mechanical polishing process (CMP), epitaxial (Epi) deposition, and the discovery and use of zero dislocation silicon crystals. MEMC made a name for These technological innovations allowed the company to grow swiftly alongside itself during the semi the booming semiconductor industry in the 1970’s and 1980’s as MEMC met boom in the 70’s and 80’s soaring demand for smaller and faster integrated circuits with further technological advancement including the development of the 125mm, 150mm, and 200mm diameter wafers. The growth required an increase in capacity which was made possible through the unveiling of new manufacturing facilities in Kuala Lumpur, Malaysia and Utsonomiya, Japan. 1995 IPO raised over The 1990’s marked a period of momentous growth for MEMC as the company $440 million, just before raised over $440 million in capital during its IPO in 1995. During that same year, the overcapacity in 1998 MEMC decided to purchase the granular polysilicon manufacturing facility that they had been using from Abermarle Corporation and renamed the plant Pasadena. Despite its good times, MEMC suffered a crippling setback in 1998 and 1999 as global overcapacity and demand drop off hurt it financially. With a new outlook and goal to reclaim industry leadership following these tough times, the company appointed Nabeel Gareeb as President and CEO of MEMC and looked to him to reinvent its business strategy and increase market share. Prior to joining MEMC, Mr. Gareeb held the title of COO at International Rectifier Corporation, a leading power semiconductor company, for over 10 years. 4 george.kotzias@us.calyon.com 19 August 2008

- 5. Section 1: Slicing a better wafer WFR - BUY Products and technology MEMC certainly fits the description of a pioneer as it boasts a rich portfolio comprised of over 600 patents globally with an additional 300 on file for application. Customers can take comfort in the consistent supply of fresh innovation as MEMC was the first merchant manufacturer of silicon wafers, the first to commercially produce 100mm, 125mm, 150mm and 200mm diameter wafers, and the first to create a patented defect-free wafer, among many other industry firsts. MEMC meets customers’ MEMC meets its customers’ strict specifications and offers vast flexibility since specifications and offers the application of the wafer is unique to each customer. In 1990, the company flexibility filled orders for 1,200 different wafer specifications. This figure has stretched to 2,200 in 2006 as integrated circuit and electronics manufacturer needs continue to advance. For this reason, the company makes three different types of wafers available for purchase: prime polished, epitaxial, and test grade. Choice only begins there as the customer must then decide on the composition, level of purity, crystal and electrical properties of the wafer. MEMC continues to strive toward increased wafer yield while simultaneously reducing the thickness of the wafers to benefit electronics manufacturers. MEMC’s primary product offering is the polished wafer. After growing their pure crystalline silicon wafer from granular polysilicon, it undergoes their CMP process to eliminate all surface defects which results in a smooth, mirror-like wafer. Company has begun to Silicon wafers make up the foundation of most solar cells which is why MEMC has produce 156mm wafers devoted more of its focus to the solar industry. The company has begun to for solar application produce solar grade, 156mm wafers as it seeks to facilitate the solar industry’s road to grid parity. Production of the wafer is only the first step that the company has taken in what promises to be a strong relationship in the future between MEMC and the solar industry as they expect to extend their knowledge of polysilicon and wafer production to the solar industry to spur innovation throughout, beginning with MEMC solar grade wafers. SOI allows for more Much of the company’s research is devoted toward forward progress in the complex surface designs research and development of new materials. Silicon-On-Insulator (SOI) is a novel base material for the fabrication of chips that increases the functionality without requiring large amounts of money for changes in fab equipment. This tri-layer wafer allows for more complex circuit design and ultimately leads to faster operation at lower voltages. Chemical-mechanical MEMC’s innovation is not only limited to the end product. In 1962, MEMC the polishing process pioneered chemical-mechanical polishing process, which is still an industry developed in 1962 is still standard today. The process is a combined effort between a chemical corrosive industry standard today used to weaken the silicon and a mechanical polishing pad to remove any surface defects, leaving a flat, smooth, mirror-like surface. Through the years, silicon manufacturers have spent much time and money ensuring that the wafers are not only functional, but that they enhance the user’s yield. Most wafer manufacturers use a conventional method of internal gettering (the process of moving impurities to the bulk) which requires long heating and cooling periods followed by a third, growth step which leads to variation in wafers due to high sensitivity to oxygen concentration. MEMC developed and patented a breakthrough Rapid Thermal Process (RTP) named Magic Denuded Zone (MDZ), which allows them to bypass the long heating period and control oxygen related complications by heating the wafer to over 1200°C in a matter of seconds, followed by a slightly lengthier, more controlled cooling period. MDZ gives manufacturers a newfound freedom in working with the silicon while also reducing processing cost to the manufacturer. 19 August 2008 george.kotzias@us.calyon.com 5

- 6. Section 2: Cash sweet cash WFR - BUY Cash sweet cash Cash heavy balance sheet WFR’s $1.4bn in cash and equivalents in 2Q08, along with estimated FCF/share reveals ability to benefit of $2.94 in 2009 is a testament to the company’s ability to benefit from the from solar and semi demand for polysilicon from the high growth solar sector, but mostly from the demand for polysilicon company’s dominance in the high margin semi industry. Our $70 price target is based on a P/E multiple of 15x 2009 earnings, which is lower than the 17.5x historical five-year P/E but inline with its peers. Our DCF analysis supports our target within a range between $58 and $93/share. Discounted Cash Flow…yes it really means something DCF analysis forecasts Using what we believe are realistic assumptions, we forecast WFR’s DCF-based WFR’s fair value to be $68 fair value is $68 per share. The table below lists our assumptions including a per share WACC of 11.1% and a 4% terminal growth rate (nominal rate based on 2.5% inflation and implies a real terminal growth rate of 1.5%). Figure 4 DCF assumptions WACC (%) 11.1 Cost of debt (%) 7.00 Tax rate (%) 25.0 Value of equity 11.7 Value of debt 0.0 Debt plus equity 11.7 CAPM Risk free rate (%) 2.00 Market return (%) 8.50 Beta 1.40 Cost of equity (%) 11.1 Source: Calyon Securities (USA) Inc. estimates Figure 5 Discounted cash flow analysis ($m) 2007A 2008E 2009E 2010E 2011E 2012E Pre-tax income 829.6 556.9 992.2 1,101.2 1,050.2 831.7 Less: Taxes & Int 20.3 443.5 125.4 123.4 93.2 242.9 EBIT 849.9 1,000.4 1,117.6 1,224.5 1,143.4 1,074.6 Add: D&A 80.7 52.2 102.8 165.6 229.2 294.6 Less: Cap Ex 276.4 420.0 407.9 506.0 512.0 526.8 Less: Change in WC (173.2) 170.2 46.2 52.6 55.4 89.9 Free cash flow 827.4 462.3 766.3 831.5 805.2 752.5 Source: Calyon Securities (USA) Inc. estimates Figure 6 Discounted cash flow analysis - equity value ($m except per share data) PV of terminal value 12,367.8 PV of free cash flows 2,617.4 Total NPV 14,985.2 Net debt (1,105.2) Equity value 16,090.4 Shares outstanding 237.7 Equity value per share 67.69 Source: Calyon Securities (USA) Inc. estimates 6 george.kotzias@us.calyon.com 19 August 2008

- 7. Section 2: Cash sweet cash WFR - BUY Figure 7 Stock price sensitivity to change in growth rate and cost of capital ($/share) Nominal growth rate (%) Cost of capital (%) 4.5 5.0 5.5 12.1 57.11 60.06 63.45 11.1 63.74 67.69 72.35 10.1 72.65 78.23 85.02 Source: Calyon Securities (USA) Inc. estimates. Execution misfires present opportunity Lingering concern of Incidents that have occurred recently include a fire and an equipment failure in stolen talent may point to Merano, a tropical storm, and a chemical buildup in Pasadena. These are some of cause of execution the events that have occurred over the course of the last year or so that have problems assisted WFR’s shares in gaining membership to the 52-week low club. Are these execution missteps purely bad luck? Or are they symptoms of something more chronic? Likely the answer is a little of both. There is concern that the solar wafer industry may be stealing talent from some of the established polysilicon and wafer makers, especially in Asia where there are over 30 new polysilicon production projects underway. MEMC has been a casualty of this migration east. Figure 8 MEMC incident report since 2005 Date Incident 8/05/08 The company reported that it has taken safety precautions in preparation for heavy weather associated with Tropical Storm Edouard at its Pasadena, Texas facility. As part of these precautions, the company has moderated operations in various areas of the facility, which is currently anticipated to have approximately a two day effect on polysilicon production. 4/03/08 MEMC reported it experienced accelerated buildup of chemical deposits inside the new expansion unit ("Unit 3") at its Pasadena, Texas facility. These buildups occurred multiple times, and each instance required downtime of several days for premature maintenance to clean and re-stabilize the unit. The company also delayed the remaining maintenance (from the prior quarter) on the existing units ("Unit 1" and "Unit 2") waiting for Unit 3 to stabilize, but eventually had to perform the maintenance on Unit 2. 4/29/08 Pasadena, Texas -- a transfer line from a transport vehicle developed a leak and caused a release of STF, a raw material gas used in the manufacturing process. The leak was quickly contained by the on-site emergency response team and the flow of material was stopped. 7/23/08 The company said it suffered a "premature failure of a relatively new heat exchanger" at its Merano, Italy facility, while a loose pipe fitting caused a fire at its Pasadena, Texas facility during the quarter. 9/04/07 A construction incident caused by one of its electrical subcontractors working on the Pasadena, Texas, polysilicon facility expansion resulted in a power outage to the entire site. Although the power was eventually restored later the same day, the unplanned and abrupt shutdown of high temperature and pressure chemical operations caused considerable complications. The facility is now in the late stages of recovery, but the abrupt nature of this incident, combined with the rain and thunderstorms in Pasadena, Texas over the last few days, has hampered the facility's ability to recover operations expeditiously. This disruption has also caused the on-going polysilicon expansion project at the site to be additionally delayed. 9/26/05 Pasadena, Texas -- The company reported that its employees in the Pasadena area are safe and that business resumption activities had begun on Sunday. The facility itself sustained no major damage from hurricane Rita. Prior to the hurricane, MEMC had safely evacuated employees from this facility. Source: Company report, Calyon Securities (USA) Inc. Market is pricing in a lack The bad news for the stock is that the market generally fears the unknown, and of talent and any the unknown in this case is how much was due to lack of talent in key positions improvements will boost and how much was due to uncontrollable events that are inevitable in the value of the stock business of manufacturing polysilicon. The good news for investors is that the market is pricing in a lack of talent. Placing the right talent in key positions is a problem that senior management can address and correct (and in some cases WFR has already made key personnel changes). We are confident that execution, and therefore the value of the stock, will improve at MEMC. Last 2 quarters of misses In WFR’s last two quarters, the company missed Street EPS estimates by 9% in tarnish a long history of 2Q and 1% in 1Q. Previously, the company had beat earnings estimates for 9 beating expectations consecutive quarters dating back to its last earnings miss in 3Q05. 19 August 2008 george.kotzias@us.calyon.com 7

- 8. Section 2: Cash sweet cash WFR - BUY Trading at rock bottom Trading at relatively low We believe WFR’s shares are attractively valued relative to historical trading multiple of 11x forward ranges. As can be seen in the figure below, at 11x its forward P/E, WFR is trading P/E suggests bottom of at near its 5-year low of 9x and substantially below its 5-year high of 29x and 5- the cycle has been reached year average of 17.5x. The relatively low multiple suggests that we are at the bottom of the cycle in the highly cyclical semiconductor industry. While all of the evidence points to a bottom, the important question is will demand recover soon? Or will we stay at the bottom for a prolonged period of time… Figure 9 Historical forward P/E 35.0 (P/E) Forward P/E 5 yr avg P/E 30.0 25.0 20.0 15.0 10.0 5.0 0.0 5/23/03 5/23/04 5/23/05 5/23/06 5/23/07 5/23/08 Source: Factset, Calyon Securities (USA) Inc. Signs of a semi rebound? Multiple expansion would We believe that semi demand may be showing signs of life, as recent reports be justified if we see the indicate an increase in wafer sales. Applied Materials (AMAT – NR) recently semi cycle reverse posted strong Q2 results and indicated a 30% increase in equipment orders from foundries and DRAM. This indicates some hope (but not proof) that a recovery may come sooner rather than later. As MEMC increases its capacity to produce polysilicon and 300mm wafers, we need to see a return to capital spending by the chip makers, DRAM makers and foundries. A confirmed increase in demand would justify multiple expansion from our 15x number. Anecdotal evidence of Besides AMAT’s favorable comments on demand, we have heard other semi recovery incrementally positive comments from our channel checks and from industry associations. SEMI reported this month that global silicon wafer shipments were 2,303 million square inches (MSI) in 2Q08. This is up 4.6% Y/Y from 2,201 MSI in 2Q07, and up 6.5% Q/Q from 2,163 MSI in 1Q08. According to Kazuyo Heinink who is the chairwoman of SEMI and also, more importantly for investors, Vice President for New Product Marketing at MEMC, “this growth was mainly attributed to 300mm” where MEMC is growing to over 700k wafers per month in 2010 from under 400k per month by year end 2008. Setting the bar too low to miss MEMC reduced FY08 MEMC lowered its full year 2008 guidance for both top and bottom line by $150 guidance to compensate to $175 million and $0.30 to $0.50 per share respectively to compensate for a for execution problems mix of its execution problems as well as weakness in semi demand. Original and weak semi demand guidance was for earnings of $4.50 to $4.60/share on annual revenues of $2.4 to $2.5 billion. Revised guidance for the year is $2.25 to 2.35 billion in revenues and EPS of $4.00 to $4.30/share. In tandem with its lower guidance, the company scheduled a mid-quarter progress update for September 2nd. We 8 george.kotzias@us.calyon.com 19 August 2008

- 9. Section 2: Cash sweet cash WFR - BUY believe that the progress update will be positive and act as a positive catalyst for the stock leading into 3Q results. Growing Capacity and Revenue Growth in market share WFR’s growth in market share has been reflected by its growth in polysilicon reflected by growth in capacity and revenue. The compnany has undergone an aggressive capacity polysilicon capacity and buildout over the past few years and we expect it to reach 15,000 MT of revenue polysilicon by 2010, translating into approximately $3.2 billion in total revenue in 2010, a Cagr of approximately 36% and 18% since 2004 for capacity and revenue, respectively. Figure 10 WFR polysilicon capacity and revenue growth: 2004 - 2010E 16,000 (MT) ($M) $4,000 14,000 $3,500 12,000 Polysilicon capacity $3,000 Total revenue 10,000 $2,500 8,000 $2,000 6,000 $1,500 4,000 $1,000 2,000 $500 0 $0 2004A 2005A 2006A 2007A 2008E 2009E 2010E Source: Company reports and Calyon Securities (USA) Inc. estimates Margins will remain WFR has been able to increase margins in tandem with volume. Favorable pricing attractive in the near for wafers and polysilicon coupled with an improved mix of 156mm solar wafers, term 300mm wafers and polysilicon sales. We expect margins to remain attractive in the near term as the semi industry’s transition to 400mm wafers remains distant and the poly shortage continues through 2009. Figure 11 Gross margin and operating margin: 2004 – 2008E 60.0 (%) Gross margin Operating margin 50.0 40.0 30.0 20.0 10.0 0.0 2004 2005 2006 2007E 2008E Source: Company reports and Calyon Securities (USA) Inc. estimates 19 August 2008 george.kotzias@us.calyon.com 9

- 10. Section 2: Cash sweet cash WFR - BUY A strong financial position We believe WFR is well positioned to weather the solar shake-out that we see will protect WFR from looming due to its strong cash generating capabilities and its robust balance looming solar shake-out sheet. We believe WFR’s strong financial position will act as a protective shield during difficult operating environments as well as enable the company to make strategic investments and acquisitions while others may be sidelined or susceptible to takeovers themselves as the result of a lack of cash. Figure 12 Net debt to net debt plus equity 20 0 -20 -40 -60 -80 -100 (%) -120 -140 2004 2005 2006 2007 2008E 2009E 2010E Source: Company reports and Calyon Securities (USA) Inc. estimates Possibility for earnings Strong revenue growth, resulting from increased volume, coupled with continued upside and margin cost improvements should lead to widening margins in the near-term. Following expansion could come this fruitful near-term period we believe growth and expansion will level off due from a strategic acquisition to the aforementioned threats to polysilicon producers and transitions taking place in the industry. We believe margins and growth will be sustained at attractive, albeit lower, levels during this period; however, we believe WFR will be uniquely positioned in the solar industry at this point due to its strong financial position. We see the possibility for earnings upside and continued margin expansion resulting from a strategic acquisition made before WFR reaches this phase of slowing growth. Figure 13 Revenue and EBITDA estimates ($m) 4000 ($M) ($M) 1600 3500 1400 3000 Net sales 1200 EBITDA 2500 1000 2000 800 1500 600 1000 400 500 200 0 0 2004 2005 2006 2007 2008E 2009E 2010E Source: Company reports and Calyon Securities (USA) Inc. estimates 10 george.kotzias@us.calyon.com 19 August 2008

- 11. Section 2: Cash sweet cash WFR - BUY WFR will continue to Steadily increasing free cash flow has led to a sharp reduction in total debt as a deliver strong FCF per percentage of total capital. We believe WFR will continue to deliver strong free share to shareholders cash flow per share to shareholders into the foreseeable future with growth levelling off from its 2007 high. Figure 14 Free cash flow per share: 2004 – 2012E $3.50 $3.00 $2.50 $2.00 $1.50 $1.00 $0.50 $0.00 2004A 2005A 2006A 2007A 2008E 2009E 2010E Source: Company reports and Calyon Securities (USA) Inc. estimates WFR will likely continue We expect debt as a percentage of total capital to have trailed off to to maintain low level debt approximately 1% at the end of this year from approximately 21% during 2004. relative to capitalization We believe WFR will continue to maintain a low level of debt relative capitalization. Figure 15 Debt as percentage of Total debt to total capital total capital to trail off to ~1% at year end 25.0 (%) 20.0 15.0 10.0 5.0 0.0 2004 2005 2006 2007 2008E Source: Company reports and Calyon Securities (USA) Inc. estimates 19 August 2008 george.kotzias@us.calyon.com 11

- 12. Section 3: Spending it wisely WFR - BUY Spending it wisely There may be considerable upside to WFR’s valuation pending management’s use of the company’s substantial free cash flow. Although the company has been proactive in buying back shares and returning value to shareholders, we would applaud some cash being returned to shareholders in the form of a dividend, which the board has been considering. A value creating acquisition such as a solar wafer maker would also improve our outlook as the company could apply its years of semi wafer technology to improve the quality and therefore margins on solar wafers. What to do with all that cash WFR is sitting on a pile of cash, with $1.1 billion in cash and equivalents alone at the end of 2Q08. Why aren’t they giving out that cash right now? Well most of the current board members are survivors of the late 90’s and early 00’s when cash was tight due to the tech implosion. In our model we forecast the company reaching in excess of $2.4 billion in 2012 (assuming no dividends). Still plenty of buyback to The company already has a share buyback program in place with a board be done authorized amount of $1 billion which was approved in 2Q. This is twice the amount of the $500 million which was initially approved in May 2007. As of June 30, 2008 the company had already bought back 4.04 million shares for a total of $270 million. Share buyback program is The possibility of a dividend has also been discussed at MEMC’s board meetings, preferred method of however it seems that the preferred way of paying back shareholders is through rewarding shareholders the buyback program. A dividend policy, if implemented, would be a token over dividend policy amount, but could act as a catalyst as the company would be exposed to an additional class of investor that is either required or compelled to own dividend paying stocks. Competition heating up in solar, cooling in semi New entrants in poly face high barriers to entry as high capital requirements, technical barriers, equipment procurement and long lead times make it difficult to gain a foothold. MEMC’s competitors include Hemlock, SUMCO, Soitek, Wacker, LDK, Shin-etsu, Covalent, LG Siltron and REC. Vertical integration in solar MEMC may be shopping MEMC is already integrated from poly to wafer on the semiconductor side of its for a cheap wafer maker business, however on the solar side of the house the company outsources its wafering to 3rd parties. In 2009 the company plans to bring its solar wafering in- house, retaining more margin power in the process. More importantly, the company’s R&D shop is chomping at the bit to apply years of extensive research in semiconductor wafer enhancement technology to solar. Management is confident that they can improve margins on solar wafers by improving the watts per wafer, the basis of their pricing on solar wafer sales contracts. The decision to bring solar wafering in-house has launched what we believe is a global search for a wafer maker. Most wafer makers are located in Asia and include companies like LDK (LDK US), M. Setek, Renesola (SOL US), and Sino- American Silicon. We also would not rule out the eventual possibility of forward integration into the cell manufacturing segment if they develop a process whereby cell architecture is designed around a proprietary MEMC wafer. We believe that WFR is well positioned to capitalize on the opportunity that the demand for solar energy presents. The need for alternative sources of energy has never been greater. The EIA estimates that world marketed energy consumption 12 george.kotzias@us.calyon.com 19 August 2008

- 13. Section 3: Spending it wisely WFR - BUY will grow by 110% over the 2000 to 2050 period. This onslaught of growth is mainly attributable to strong growth in energy demand among non-OECD nations. Figure 16 World electric power generation 35,000 30,000 OECD Non-OECD 25,000 20,000 15,000 10,000 5,000 0 2000 2002 2004 2006 2008 2010 2012 2014 2016 2018 2020 2022 2024 2026 2028 2030 Source: EIA Need for energy A need for alternative fuel sources brought on by this growth in energy demand alternative exacerbated has been exacerbated by the steady rise in carbon dioxide emissions as well as in by rise in CO2 emissions the rapid rise in the price of fuel and electricity. We believe solar energy is one of the foremost candidates to help meet global energy demand, curb energy prices and abate carbon emissions. Figure 17 Figure 18 Crude oil & natural gas prices: 1986 - Present World carbon dioxide emissions: 2005 – 2030E $/BBL $/Mcf 45 WTI Oil (L-Axis) Natural Gas (R-Axis) $16 OECD Non-OECD 40 $140 (Billion metric tons) $14 35 $120 $12 30 $100 $10 25 $80 $8 20 $60 $6 15 $40 $4 10 $20 $2 5 $0 $0 0 1986 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2005 2010 2015 2020 2025 2030 Source: Bloomberg and EIA Technical innovator Through its progressive in-house R&D program and a series of acquisitions, WFR has been able to maintain its edge as a technological innovator in the ever changing and performance demanding polysilicon industry. Fundamental research conducted in the 1960’s led to the zero-dislocation silicon crystals that allowed WFR to grow in-line with the booming semiconductor industry in the 1970’s and 1980’s. 19 August 2008 george.kotzias@us.calyon.com 13

- 14. Section 3: Spending it wisely WFR - BUY Since WFR’s entrace into the solar industry in 2006 the company has focused on offering higher grade polished wafers. The company offers three WFR offers three general categories of wafers that include prime wafers, epitaxial different types of wafers wafers and test / monitor wafers. Prime wafers are polished, highly refined pure including prime, epitaxial, wafers with an ultraflat and ultraclean surface. WFR’s premium brand prime and test grade wafer is called the OPTIA wafer. The OPTIA wafer is a defect-free crystalline structure that incorporates patented technologies and processes, such as the Magic Denuded Zone, which increases yield by drawing impurities away from the wafer surface. Figure 19 Wafer category offerings Type Characteristics Premium brand name Prime wafers Polished, highly refined, ultraflat & clean surface OPTIA Epitaxial wafers Superior isolation between circuit elements AEGIS Source: Company reports Epitaxial wafers have a thin silicon layer grown on the polished surface of the wafer and provide superior isolation between circuit elements versus a polished wafer. WFR’s proprietary epitaxial wafer, AEGIS, also incorporates Magic Denuded Zone and has a thin eqitaxial layer grown on a standard starting wafer that elimates harmful defects on the wafer surface. WFR also offers test / monitor wafers for the testing of semiconductor fabrication lines and processes. These wafers are produced from the portion of silicon ingot that does not meet certain specifications but are similar to prime wafers in regard to cleanliness and flatness, in some cases. Increasing GOI yield The company sells higher grade polished wafers under their trademark Advanta. The wafer offers customers a cost effective product that includes a higher yield and better performance for integrated circuits. Advanta is aimed at next generation integrated circuits and has low levels of crystal originated pits (COPs) on the surface while also boosting performance with higher gate oxide integrity (GOI) of 81.8. For even better performance, the company’s trademark Optia wafer is entirely COP free and has a superior GOI of 98.6 which makes it an ideal long term solution for advanced integrated circuits. Figure 20 GOI yield by MEMC wafer 100 (%) 95 90 85 80 75 70 Advanta Optia Aegis Source: Company Reports 14 george.kotzias@us.calyon.com 19 August 2008

- 15. Section 3: Spending it wisely WFR - BUY MEMC wafers increase Manufacturers of advanced semiconductor devices demand greater functionality functionality through more complex circuits. As the size of the circuit is reduced, insufficient electrical isolation between the elements becomes a problem. MEMC offers its epitaxial wafers as the solution. Epitaxial wafers were created to increase the reliability of the semiconductor device and provide higher efficiency by growing a thin, single crystal silicon layer above the polished surface having different electrical and compositional properties. Their trademark epitaxial wafer, Aegis, is a cost effective alternative to the prime polished wafer with the difference lying in the COP free zone which only exists in the epi layer of the wafer rather than the entire bulk. Weaker semi demand increases solar appeal There is excess memory and processor capacity at the enterprise level due to the emergence of virtualization and improved software efficiency. Some estimates suggest that 65% or more of existing capacity is idle, as software efficiency has reduced the strain on memory and processor capacity. The internet has allowed companies to manage their global server network much more efficiently, as over- utilized servers can communicate with underutilized or idle servers and share the computing load. The in-house advantage WFR produces granular MEMC puts itself at a huge advantage against its competitors by making its own polysilicon in-house granular polysilicon to use as the raw material for wafer manufacture. Granular polysilicon processing is a far more efficient process that supports higher growth yield. The continuous throughput is an improvement to the Siemens process. In the more common and lower barrier to entry Siemens process, a high purity silicon rod receives exposure to trichlorosilane gas at high temperatures exceeding 1100°C. The chemical reaction causes additional silicon from the gas to be deposited onto the rod. MEMC uses the more efficient fluidized bed reactor (FBR) process to produce its granular polysilicon which has helped lower material costs in its wafer production. The FBR process makes this possible by consuming 80% - 90% less energy while allowing for greater yield, productivity and product purity. Figure 21 MEMC manufacturing and R&D plants MEMC Year Name Location Ownership Products Completed 100mm, 125mm, 150mm, 200mm and St. Peters, 300mm single-crystal CZ silicon; 100mm, St. Peters 100% 1959 Missouri 125mm,150mm, 200mm Polished and Epitaxial CZ silicon wafers Sherman, 200mm single-crystal CZ silicon; 200mm Southwest 100% 1997 Texas Polished and Epitaxial CZ wafers Semiconductor-grade Granular Polysilicon, Pasadena, Pasadena 100% Monosilane and SiF4 Gases, 1995 Texas Semiconductor-grade silicon powder Utsunomiya- 125mm, 150mm, 200mm and 300mm Utsunomiya city, Tochigi, 100% polished CZ silicon wafers; 200mm and 1986 Japan 300mm epitaxial CZ silicon wafers Hsinchu, Hsinchu 100% Polished and Epitaxial Wafers 1996 Taiwan Petaling Kuala Jaya, 100% Polished 1970 Lumpur Malaysia Chonan, Korea 80% Polished Wafers 1993 Korea Novara Novara, Italy 100% Polished and Epitaxial Wafers 1976 Merano Merano, Italy 100% Single Crystal and Polysilicon 1976 Source: Company Reports 19 August 2008 george.kotzias@us.calyon.com 15

- 16. Section 3: Spending it wisely WFR - BUY Growth: From semiconductors to solar Experience during Over the past three decades WFR has enjoyed strong growth in the semiconductor boom will semiconductor industry. We believe WFR will be able to leverage off the technical translate into rapidly experience it received during the seminconductor boom as well as benefit from growing solar industry the trials it experienced operating in a rapid growth industry, which it faces once again. Rapid growth in semi As highlighted by figure 22, the semiconductor industry has achieved robust and industry is marked by a rapid growth underlined by strong demand in the early 1990’s and 2000’s. 67 fold increase from According to the Semiconductor Industry Association, global semiconductor 1977 billings for the semiconductor industry have grown to approximately $255 million from approximately $4 million in 1977, a 67-fold increase. Figure 22 Semiconductor global billings: 1977 - 2007 300 ($ MM) 250 200 150 100 50 - 1977 1979 1981 1983 1985 1987 1989 1991 1993 1995 1997 1999 2001 2003 2005 2007 Source: Semiconductor Industry Association Emergence of growth WFR has been able to use its semiconductor segment as a cash cow since the prospects in solar has semiconductor industry has reached a stage of maturity. However, the caused WFR to shift focus emergence of the solar industry has prompted WFR to shift its focus from the away from semi industry semiconductor industry to the growth prospects presented by the solar industry, as reflected in figure 23. Figure 23 Semi wafer revenue & semi wafer revenue as a % of total sales 2,000 Semi wafer revenue % of sales 100% 1,600 80% 1,200 60% 800 40% 400 20% 0 0% 2008E 2009E 2010E 2011E 2012E 2004A 2005A 2006A 2007A Source: Company reports and Calyon Securities (USA) Inc. estimates 16 george.kotzias@us.calyon.com 19 August 2008

- 17. Section 3: Spending it wisely WFR - BUY Growth prospects by We estimate that the growth prospects presented by the c-Si solar industry will polysilicon for solar will reach almost $70 billion by 2015, growing at a CAGR of approximately 30% over be ~$70bn by 2015 that period from current levels. Figure 24 C-Si market value: 2006 – 2015E 100,000 90,000 ($m) 80,000 70,000 60,000 50,000 40,000 30,000 20,000 10,000 0 2007A 2008E 2009E 2010E 2011E Source: Calyon Securities (USA) Inc. estimates Tight polysilicon market This rapid growth places a demanding and stressful supply scenario on polysilicon will persist through 2010 producers. We believe the tight polysilcion market will persist through 2010 with as demand outstrips demand outstripping supply. These favourable market conditions for incumbent supply polysilicon producers could exceed our estimates as new entrants struggle to bring additional supplies to the market. Figure 25 Polysilicon supply/demand balance 5,000 (MW) 4,000 3,000 2,000 1,000 0 (1,000) (2,000) (3,000) (4,000) 2006A 2007A 2008E 2009E 2010E 2011E 2012E 2013E 2014E 2015E Source: Calyon Securities (USA) Inc. estimates Talent drain in industry The experience, economies of scale and talent that WFR possesses are the exact will leave inexperienced factors contributing to the delay in excess polysilicon available for the market. A entrants with large delays wave of Chinese polysilicon is set to enter the market; however, it is set to come on-line much slower-than-expected due to the underestimation by these new- comers of the complexities of the technology, design, trial and production process. A talent drain in the industry, which WFR has acknowledged, will more- than-likely leave the inexperienced Chinese new entrants the most susceptible to delays. 19 August 2008 george.kotzias@us.calyon.com 17

- 18. Section 3: Spending it wisely WFR - BUY Polysilicon market will Figure 26 illustrates the expected output in Chinese polysilicon production this remain tight in year as reported by China Reality Research (CRR). CRR has been tracking the foreseeable future progress of 22 Chinese polysilicon producers through various plant visits and has reinforced our belief that the polysilicon market will remain tight for the foreseeable future due to slower-than-expected Chinese production. Figure 26 Estimated Chinese polysilicon output in 2008 4,000 (MT) 3,500 3,000 2,500 2,000 1,500 1,000 500 - C RR estimate of actual output With upside Source: China reality research – CLSA Asia Pacific Markets Eventual flood of poly is Globally, we attribute approximately 40% of a discount to this factor and to come currently predict that only 162,000 MT of poly will be available for the solar market by 2012 versus the 265,000 MT that has been announced. While we believe a large amount of this poly should be discounted due to an expected delay, we also remain wary of this eventual and unavoidable flood of poly that is not a matter of if it will come, but when it will come. Figure 27 Figure 28 Expected poly capacity versus announced poly capacity Announced capacity – new entrant breakdown 300,000 300,000 (MT) (MT) 250,000 250,000 Wildcards Discounted capacity 200,000 New producers-traditional process 200,000 New producers-emerging processes Expected capacity Established producers 150,000 150,000 100,000 100,000 50,000 50,000 - 0 2007 2008 2009 2010 2011 2012 2006 2007E 2008E 2009E 2010E 2011E 2012E Source: Calyon Securities (USA) Inc. estimates Serving wafers worldwide MEMC’s wafers are used by some of the best known names in tech and solar globally. In 2007, only two of MEMC’s customers, Samsung and Yingli Green Energy (YGE US) represented more than 10% of sales. In addition to Yingli in the solar segment, the company has signed long term wafer supply contracts with Suntech (STP US), Gintech (3514 TT), Conergy (CGY GR), and Tainergy. MEMC’s 18 george.kotzias@us.calyon.com 19 August 2008

- 19. Section 3: Spending it wisely WFR - BUY solar contracts typically require significant deposits and in some cases MEMC acquires rights (as in the case of warrants on STP’s shares) to the company’s equity. In tech, wafers can be found just about everywhere. The end users of semi wafers include many well known names like IBM, Apple, HP, Cisco, Nokia and Dell among others. Figure 29 MEMC has secured over MEMC's announced long-term solar wafer supply contracts $15bn in long-term solar Company Term Size wafer contracts Suntech 10 year $5-6 billion Gintech 10 year $3-4 billion Conergy 10 year $4 billion* Tainergy 10 year $3-3.5 billion Total 10 year $15-17.5 billion Source: Company reports. Note: Conergy contract reduced from $7-8bn Potential Q2/Q3 catalyst Upcoming catalysts ! 23rd European Photovoltaic Energy Conference and Exhibition in Valencia, Spain on September 1-5, 2008 ! MEMC mid-quarter status call on September 2nd to update investors on the poly production ramp ! Increased evidence of strength in semi equipment orders would increase confidence in semi wafer demand which is one of the key reasons for the stock poor performance as of late ! Passage of solar ITC in the U.S. which could happen some time in the fall upon Congress returning to session from summer holiday ! Solar Power International Conference in San Diego, USA on October 13-16, 2008 19 August 2008 george.kotzias@us.calyon.com 19

- 20. Section 4: China rising WFR - BUY China rising Uncertainties include up There have been great expectations for the ramp up of new polysilicon, but and coming Chinese poly supply from more than 30 eager Chinese poly producers has yet to materialize. producers, thin-film and The production which was expected by 2009, has been slow, as new entrants UMG-Si have find it technically challenging to enter the market. As a result, spot poly is still over $400 per kilogram. The meteoric rise of thin-film solar technology should also help ease demand for the semiconducting material along with the advancement of lower purity UMG-Si that is also on the radar. We feel confident that management will address and be able to stay in front of the ever-changing solar landscape. Thin-film: Poly enemy #1 Thin-film poses a threat The unexpected success of thin-film poises a major threat to c-Si producers. to WFR Assumptions made just a few years ago that thin-film technologies would not be able to compete with the efficiency-superior c-Si technologies have since been retracted as thin-film continues to lead the industry in terms of yeild and growth. Figure 30 c-Si and thin-film demand 30,000 (MW) 25,000 20,000 Thin-film c-Si 15,000 10,000 5,000 0 2007A 2008E 2009E 2010E 2011E 2012E Source: Photon international and Calyon Securities (USA) Inc. estimates Thin-film may capture Thin-film companies, such as FSLR and ENER, have capitalized on the tight 20% of market share in polysilicon supply market by increasing market share. We believe thin-film may 2008 capture 20% of market share in 2008, up from 12% in 2007 and 7% in 2006. Figure 31 Share of competing PV technologies Ribbon c-Si a-Si 4% 7% C dTe 5% Mono c-Si 39% Multi c-Si 45% Source: Calyon Securities (USA) Inc. estimates 20 george.kotzias@us.calyon.com 19 August 2008

- 21. Section 4: China rising WFR - BUY Aside from acting as an alternative for c-Si, thin-film has the advantage of versatility and adaptability. Thin-film solar cells are flexible, making them c-Si can lose efficiency in versatile and able to be integrated into various structures, such as buildings. high temperature Building integrated photovoltaic (BIPV) panels are still in a relatively early environments commercial stage; however, we believe the technology has strong potential. Thin-film cells are also able to withstand hot weather much better than c-Si, which can lose efficiency in high temperature environments. This adaptability to extreme climate conditions sets c-Si back in the bid to win some of the most promising emerging markets that have yet to garner much attention, such as the Middle East and Africa. Figure 32 Many untapped solar markets are also the hottest Source: NASA Thin-film is likely to be Most importantly, thin-film leads the sector in pricing and is likely to be the first first technology to technology to achieve grid parity. While we recognize the importance of cell achieve grid parity efficiency and the effect that reducing wafer size has on pricing, we also believe that in the end these increases in efficiency need to translate into a steep reduction in price per watt. In our recent report, Survey of U.S. Solar Integrators, we found that the majority of customers are more interested in price per watt than power density. Figure 33 Figure 34 Module ASP forecast for c-Si and thin-film Importance of cell efficiency to solar integrators 10.0 ($/Wp 45.0 9.0 (%) 40.0 8.0 35.0 7.0 30.0 6.0 25.0 5.0 20.0 4.0 15.0 c-Si ASP 3.0 10.0 Thin film ASP 2.0 5.0 1.0 0.0 0.0 Not important Somewhat Important Very Most important important important 2006A 2008E 2010E 2012E 2014E Source: Calyon Securities (USA) Inc. estimates Source: Calyon Securities (USA) Inc. – Survey of U.S. Solar Integrators 19 August 2008 george.kotzias@us.calyon.com 21