Instrumentation

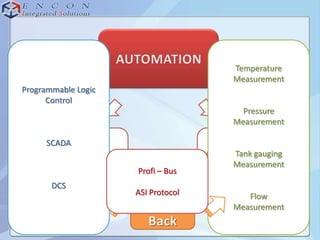

- 1. Temperature Measurement Programmable Logic Control Pressure Measurement SCADA Tank gauging Measurement Profi – Bus DCS ASI Protocol Flow Measurement

- 3. Pressure Te m p e r a t u r e Ta n k G a u g i n g Measurement Flow Metering Systems

- 4. Pressure

- 5. Pressure - Definition Pressure is the FORCE per Unit AREA F P gh A Pressure is Directly proportional to the Material (Liquid – Gas) Density & Height in the Storage Container

- 6. Pressure - Definition Pressure Measurement WHY ?? HOW Pressure Pressure is measured for Measuring Device the following: Level Pressure Pressure Transducer Transmitter Flow Element that Element that converts the converts the pressure into Checks Mechanical value to 4-20mA Electric Signal Value

- 7. Pressure - Definition Pressure REFRENCEs Absolute Gage Differential

- 8. Pressure - Indicators Pressure Indicators Bourdon Diaphragm Tube Gage Pigtail Siphon

- 9. Pressure - Indicators Bourdon Tu b e Consist of a Bent Oval Tube • One End connected to the PROCESS PRESSURE • The other End to the Mechanism operating the POINTER As the pressure increase the Tube tend to become CIRCULAR from OVAL This movement is detected by the POINTER MECHANISM

- 10. Pressure - Indicators NO PRESSURE Diaphragm G a g e The Diaphragm is EXPOSED to the DIAPHRAGM NO PRESSURE PROCES RESSURE This will make the Diaphragm to 15 psig BEND Over This bending is detected by the pointer DIAPHRAGM 15 psig mechanism which detects the pressure PROCESS PRESSURE Diaphragm PRESSURE

- 11. Pressure - Indicators P i g - Ta i l Siphon This INDICATOR usually used in measuring the STEAM Pressure The Oval Path is for: • Condensing the vapor to insure that the steam wont reach the measuring Element. • Isolating the HOT VAPORS from the measuring elements

- 12. Pressure - Switch Pressure Switch Monitoring Take Action due to the Pressure Measured Pressure

- 13. Pressure - Switch Pressure Pressure Measuring Device Element Consist of Switch Electrical System or Contact WHEN The Pressure reaches a certain Limit the Switch sends an Electrical Signal indicating that the Pressure reached a certain Limit. WHY ?? This Electrical Signal is sent to a RELAY or PLC input to START/STOP an operating Equipment ( PUMP – ALARM – VALVE – PROCESS ) PRESSURE RELAY ELECTRIC SWITCH SOURCES ELECTRIC EQUIPMENT PROCESS I.O. PUMP PRESSURE ANNUNCIATOR

- 14. P r e s s u r e - Tr a n s m i t t e r Pressure Transmitter Capacitance Piezoelectric Differential

- 15. P r e s s u r e - Tr a n s m i t t e r Capacitance P r e s s u r e Tr a n s m i t t e r oA C d The process pressure actives 2 Diaphragms & these 2 diaphragms acts as 2 Plate Capacitors When the pressure occur the diaphragm d will bend over causing that the space (d) to increase . The thing will affect the capacitance The capacitance value is measured by electronic circuits to represent the pressure

- 16. P r e s s u r e - Tr a n s m i t t e r Piezoelectric P r e s s u r e Tr a n s m i t t e r Is a material that : • Generates Voltage when exposed to Pressure • Generates Pressure (Vibration) when exposed to Voltage The Piezoelectric Pressure Indicator When applied to process pressure this affect a diaphragm that apply a FORCE to a Piezoelectric Material. The Piezoelectric material produces a voltage corresponding to the applied force

- 17. P r e s s u r e - Tr a n s m i t t e r Differential P r e s s u r e Tr a n s m i t t e r Is a device that compares between 2 input pressures and sends the NET pressure P P1 P2

- 18. Pressure Te m p e r a t u r e Ta n k G a u g i n g Measurement Flow Metering Systems

- 19. Te m p e r a t u r e

- 20. Te m p e r a t u r e - D e f i n i t i o n Units of Measurements • Fahrenheit scale • Celsius scale • Kelvin (used mainly for scientific work) Conversions 9 F (C * ) 32 5 C K 273 . 15 Temperature Elements usually saved in a THERMOWELL To protect the element – since its FRAGILE The THERMOWELL is not required in some applications • Internal of some EQUIPMENTS • Bearings

- 21. Te m p e r a t u r e - D e f i n i t i o n Temperature WHY Measurement HOW ?? Temperature is measured Te m p e r a t u r e at the following: Measuring Device Boilers Temperature Transducer Temperature Tanks Transmitter Element that converts the Element that Pumps Bearings temperature converts the into value to Mechanical 4-20mA … etc or Electric Signal Value

- 22. Te m p e r a t u r e - I n d i c a t o r s Te m p e r a t u r e Indicators Resistance Thermocouple Temperature Detector

- 23. Te m p e r a t u r e - I n d i c a t o r s Thermocouple 2 Metals 2 Junctions Immersed in a Liquid and 1 Reference Junction Immersed in ICE or left in AIR N T n a nV n0 Advantages Disadvantages Self Powered Non-Linear output Shock Resistance Low Voltage Inexpensive Require a Reference Junction They Provide fast Response (in Seconds) LOW Sensitivity & Accuracy

- 24. Te m p e r a t u r e - I n d i c a t o r s Resistance Temperature Detector Pure Metals will produce an Increase in Resistance Increase in Temperature To T R (T ) R o T q exp T Temperature Most Known Example is PT100 Ro - To Material Parameters ((Constants)) Material got an Electrical ρ = 0.5 ((Coefficient for fine tuning & calibration)) Resistance Coefficient = 100Ω at ZERO Celsius

- 25. Te m p e r a t u r e - I n d i c a t o r s Resistance Temperature Detector How it WORKs 2-Wire Connection 3-Wire Connection 4-Wire Connection

- 26. Te m p e r a t u r e - I n d i c a t o r s Resistance Temperature Detector Advantages Disadvantages Most Stable Expensive Most Accurate Require Current source Sensitive Have Limited Temperature Range Linear Accuracy Varies with Temperature Require no REFERENCE When to use ?? According to some Factors such as: Temperature Time Accuracy Size Very Fast Response Ranges of: (RTD) Frictions of Tolerance of: Tight Places RTD Sec. 2 Celsius Or greater -200 – 500 Celsius (RTD) Thermocouple Larger Range Large Places Larger Range (Thermocouple) Less than 2 Celsius Thermocouples (Thermocouple) Sec. RTD

- 27. Pressure Te m p e r a t u r e Ta n k G a u g i n g Measurement Flow Metering Systems

- 28. Ta n k G a u g i n g Measurement

- 29. Ta n k M e a s u r e m e n t - D e f i n i t i o n Ta n k M e a s u r e m e n t s We deal with … Level Measurements Temperature Measurements Sopot Automatic Tank Gauging MRT Radar Tank Gauging MTT

- 30. Ta n k M e a s u r e m e n t - AT G Automatic TERMINAL COMP. Ta n k G a u g i n g DRUM Electronics HOUSING ELECTRONIC Drum COMPARTMENT Housing XPU Consist of: SPU Option 1. Floating Displacer F Power 2. Drum + Stepper Motor B 3. Force Transducer 4. Electronics W

- 31. Ta n k M e a s u r e m e n t - AT G Floating Displacer

- 32. Ta n k M e a s u r e m e n t - AT G Theory of Operation The displacer is placed into the Container on the Liquid surface The cable holding the displacer got a specific Tension detected & measured by the Force Transducers DRUM MOTOR If the Liquid level go UP & DOWN This tension differs than Specific Value WEIGHT MOTOR Here the Micro-Processor takes the FORCE MEAS CONTROL TRANSD decision to start Rotating the Stepper UCER Motor Connecting to the DRUM to move CONTROL ELECT. the displacer upward or downward till the force transducer measures the specific value APPARENT WEIGHT Numbers of Revolutions done by the stepper motor is equivalent to the level

- 33. Ta n k M e a s u r e m e n t - R T G R A D A R Ta n k G a u g i n g Radar is an excellent technology to locate 'invisible' objects distance of object is located using radio waves Level measurement is distance measurement radar technology is adapted for accurate level measurement inside storage tanks

- 34. Ta n k M e a s u r e m e n t - R T G Principles of pulse Radar Elapsed time Dt is measured a m p l. Time Dt = 2d / C Example Dt = 50 ms d = ½ · 50·10-6 · 3·108 = 7500 m t Conclusion t pulse radar is not suitable for high accuracy on short distances antenna f object oscillator detector t t t distance d

- 35. Ta n k M e a s u r e m e n t - R T G Introduction Saab TankRadar is a powerful radar level gauge suitable for non-contact level measurements in process tanks, storage tanks and other types of tanks. The modular hardware and software design makes it possible to specify a TankRadar Pro gauge that will meet your requirements. It can be used as a stand-alone unit, or it can be connected to various control systems. You can integrate TankRadar Pro in your own Local Area Network (LAN). By using the Saab TRL/2 Bus interface you can easily connect Pro gauges to a Saab TankRadar L/2 supervisory system.

- 36. Ta n k M e a s u r e m e n t - R T G

- 37. Ta n k M e a s u r e m e n t - R T G Integrated Tank Gauging System

- 38. Ta n k M e a s u r e m e n t - Te m p e r a t u r e Ta n k Te m p e r a t u r e Temperature Measurement Elements Spot MRT MTT Un Rt Tn R0......R11 Rt + low cost + aver. prod. temp. + aver. prod. temp. + simple & + vapour temp. + vapour temp. reliable ++ sturdy & reliable ++ temp. profile

- 39. Ta n k M e a s u r e m e n t - Te m p e r a t u r e MTT Construction

- 40. Ta n k M e a s u r e m e n t - Te m p e r a t u r e MT T V. S MRT MRT MTT 0.5 C 0.1 C i level area not measured by MRT 0.2 C 0.1 C

- 41. Pressure Te m p e r a t u r e Ta n k G a u g i n g Measurement Flow Metering Systems

- 43. Turbine Meters

- 44. Tu r b i n e M e t e r s - C o n s t r u c t i o n Meter C o n st r u c t i o n A Rotor attached to: Bearing & Shaft

- 45. Tu r b i n e M e t e r s - C o n s t r u c t i o n Rotor Consist of a group of Blades fixed at a specific angle causing rotation when the fluid stream For Less than 6” Larger Meters Meter Types Types Rimmed Rotors Open Bladed WHY? made of To increase the PULSE resolution Stainless Steel by adding more Or detection points Ferro Magnetic per rotor Material revolution

- 46. Tu r b i n e M e t e r s - C o n s t r u c t i o n Bearing is a Hard Surface Journal Good Bearing is IMPORTANT Why ?? Long Service Life Good Repeatability Good Accuracy

- 47. Tu r b i n e M e t e r s – P u l s e C o u n t e r Counting Pulses Coil Many thousands turns of fine wire wrapped around a ferromagnetic material The rotor rotates due to flow & the Coil + Magnet counts the magnetic buttons & send these pluses to the AMPLIFIER to amplify the signal…

- 48. Tu r b i n e M e t e r s M ete r Performance Curve

- 49. Tu r b i n e M e t e r s Factors Affecting Meter Accuracy Cavitations Velocity Profile & Swirl

- 50. Tu r b i n e M e t e r s Flow Conditioning

- 51. Tu r b i n e M e t e r s Ty p i c a l Metering Line Pressure Relief Control Valve Turbine Valve Inlet Outlet Meter Valve P T Valve Strainer & Air Separator Prover Valve

- 52. PD Meters

- 53. PD Meters Vo l u m e Measurement Principles PD Meters Directly Measure Volume by Counting Rotor Revolutions F u n c t i o n Of Measuring Element • Measure Liquid Volume • Produce Torque to Drive Meter Accessories

- 54. PD Meters F LO W Profile

- 55. PD Meters F LO W Profile

- 56. PD Meters F LO W Profile

- 57. PD Meters F LO W Profile

- 58. PD Meters P D M e t e r Inner Mechanism Rotor Gear Shaft Extended Blade Retracting Blade Measuring Chamber Rotor Inner mechanism Housing