JEFFAMINE(R) RFD-270

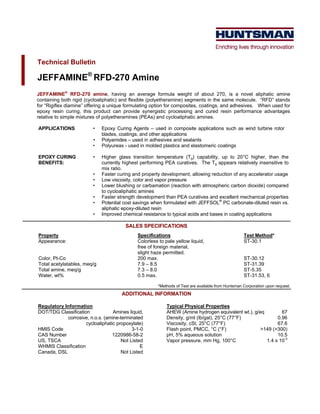

- 1. Technical Bulletin JEFFAMINE® RFD-270 Amine JEFFAMINE® RFD-270 amine, having an average formula weight of about 270, is a novel aliphatic amine containing both rigid (cycloaliphatic) and flexible (polyetheramine) segments in the same molecule. “RFD” stands for “Rigiflex diamine” offering a unique formulating option for composites, coatings, and adhesives. When used for epoxy resin curing, this product can provide synergistic processing and cured resin performance advantages relative to simple mixtures of polyetheramines (PEAs) and cycloaliphatic amines. APPLICATIONS • Epoxy Curing Agents – used in composite applications such as wind turbine rotor blades, coatings, and other applications • Polyamides – used in adhesives and sealants • Polyureas - used in molded plastics and elastomeric coatings EPOXY CURING • Higher glass transition temperature (Tg) capability, up to 20°C higher, than the BENEFITS: currently highest performing PEA curatives. The Tg appears relatively insensitive to mix ratio. • Faster curing and property development, allowing reduction of any accelerator usage • Low viscosity, color and vapor pressure • Lower blushing or carbamation (reaction with atmospheric carbon dioxide) compared to cycloaliphatic amines • Faster strength development than PEA curatives and excellent mechanical properties • Potential cost savings when formulated with JEFFSOL® PC carbonate-diluted resin vs. aliphatic epoxy-diluted resin • Improved chemical resistance to typical acids and bases in coating applications SALES SPECIFICATIONS Property Specifications Test Method* Appearance: Colorless to pale yellow liquid, ST-30.1 free of foreign material, slight haze permitted. Color, Pt-Co 200 max. ST-30.12 Total acetylatables, meq/g 7.9 – 8.5 ST-31.39 Total amine, meq/g 7.3 – 8.0 ST-5.35 Water, wt% 0.5 max. ST-31.53, 6 *Methods of Test are available from Huntsman Corporation upon request. ADDITIONAL INFORMATION Regulatory Information Typical Physical Properties DOT/TDG Classification Amines liquid, AHEW (Amine hydrogen equivalent wt.), g/eq 67 corrosive, n.o.s. (amine-terminated Density, g/ml (lb/gal), 25°C (77°F) 0.96 cycloaliphatic propoxylate) Viscosity, cSt, 25°C (77°F) 67.6 HMIS Code 3-1-0 Flash point, PMCC, °C (°F) >149 (>300) CAS Number 1220986-58-2 pH, 5% aqueous solution 10.5 US, TSCA Not Listed Vapor pressure, mm Hg, 100°C 1.4 x 10-3 WHMIS Classification E Canada, DSL Not Listed

- 2. PRODUCT PERFORMANCE DATA EPOXY CURING WITH JEFFAMINE® RFD-270 AMINE Table 1: System Reactivity Characteristics The JEFFAMINE® RFD-270 amine should be A B C mixed thoroughly with the epoxy resin (36 to 38 Part A: pbw phr with a general purpose diglycidyl ether of DGEBA resin (EEW 182-192) bisphenol A (DGEBA) epoxy resin with EEW of 100 100 100 182 to 192 such as ARALDITE® GY 250 resin and Part B: phr ARALDITE® GY 6010 resin). The reactivity JEFFAMINE® RFD-270 amine 36 - - properties of a standard liquid epoxy resin cured ® with JEFFAMINE® RFD-270 amine are illustrated JEFFAMINE D-230 amine - 32 - in Table 1 and Figure 1. In table 1, JEFFAMINE® IPDA - - 23 RFD-270 amine is compared with JEFFAMINE® D- 230 amine, the 230 MW polypropylene glycol Brookfield mix viscosity, mPa.s at 25°C 1770 470 2220 diamine from Huntsman, and also with IPDA 1 1 (isophorone diamine). In Figure 1, the initial Gel time, 200 gram mass, minutes at 25°C 180 350 94 viscosity and viscosity build at 40°C as function of Maximum exotherm temperature, °C 98 30 165 time for JEFFAMINE® RFD-270 amine is also compared with the properties for two JEFFAMINE® Time to maximum temperature, min. 300 507 103 D-230 amine/IPDA amine blends. 1 Time to reach 10,000 mPa.s (cP) Table 2: Formulations in Parts By Weight (pbw) and Glass Transition Temperature (Tg) after Different Baking Cycles A B C D E Part A: pbw ARALDITE® GY 250 resin (EEW 186) 100 100 100 100 100 Part B: phr JEFFAMINE® RFD-270 amine 38 - - - - ® JEFFAMINE D-230 amine - 32 - - - IPDA - - 23 - - ® JEFFAMINE D-230 amine / IPDA (30/70 wt%) - - - 25 - ® JEFFAMINE D-230 amine / IPDA (70/30 wt%) - - - - 29 Inflection Tg, ºC, baked 6 hrs at 80ºC (1st / 2nd heat) 100 / 109 85 / 86 118 (2) / 153 108 / 130 100 / 106 Inflection Tg, ºC, baked 2 hrs at 80ºC + 3 hrs at 125ºC 112 87 157 (1) 136 111 Inflection Tg, ºC, 7 days at 21ºC (1st / 2nd heat) 54 (2) / 106 51 (2) / 73 57 (2) / 140 55 (2) / 107 54 (2) / 90 1 Casting with IPDA was cured for 2 hrs at 80ºC + 3 hrs at 150ºC. 2 Under-cured, but to different degree. Strongest under-cure with IPDA. DSC heating rate of 20°C/min 2

- 3. Table 3: Mechanical Properties of Cured 3 mm Castings after Different Baking Cycles (ASTM D-638/ISO 527, ASTM D-790/ISO 178, ASTM D-2240) Table 2 defines formulations used for Table 3. Formulation A A B C D E 100 (with a 100 (with a ARALDITE® GY 250 resin 100 100 EEW 188 EEW 188 100 100 (EEW 186) resin) resin) 7 days at Baking cycle 2 hrs at 80°C + 3 hrs at 125°C 21ºC Shore D, 0-10 sec. 83 - 83 85 - 84 78 - 75 88 - 87 87 - 86 85 - 84 Tensile modulus, GPa (ksi) 3.26 (473) 2.47 (358) - 3.03 (440) 2.76 (400) 2.76 (400) Max. tensile strength, MPa (ksi) 15 (2.17) 66.8 (9.7) 64.8 (9.4) 73.1 (10.6) 73.1 (10.6) 77.9 (11.3) % Elongation at break 0.5 7.5 8 4 4 6 Flexural modulus, GPa (ksi) 3.4 (493) 2.51 (364) 2.95 (429) 2.89 (420) 2.86 (415) 3.02 (438) Flexural strength, MPa (ksi) 22.6 (3.28) 115.1 (16.7) 102.7 (14.9) 135.8 (19.7) 139.5 (20.2) 130 (18.8) Figure 1: Initial Viscosity and Viscosity Build at 40°C as a Function of Time Cure Profile at 40°C with undiluted standard DGEBA resin Glass transition temperature and the 5 cured resin properties of standard liquid bisphenol A epoxy resin Viscosity (in Pa.s or in cP x 10-3) (ARALDITE® GY 250 resin, EEW = 4 ® 186) cured with 38 phr of JEFFAMINE RFD-270 amine are shown in the 3 Tables 2 and 3. In these tables, JEFFAMINE® RFD-270 amine is compared with JEFFAMINE® D-230 2 ® amine, IPDA, and two JEFFAMINE D- 230/IPDA amine blends. JEFFAMINE® 1 RFD-270 amine has a higher glass transition temperature (Tg) capability, up to 20°C, than the highest 0 0 20 40 60 80 100 120 140 160 180 performing PEA curatives. Thus, Time (in min) ® JEFFAMINE RFD-270 amine offers JEFFAMINE® D-230 amine (32 phr) (172 mPa.s) improved heat resistance. With IPDA, JEFFAMINE® D-230 amine / IPDA amine blend (70/30 wt. ratio, 29 phr) (204 mPa.s) curing at an elevated temperature is JEFFAMINE® RFD-270 amine (38 phr) (330 mPa.s) JEFFAMINE® D-230 amine / IPDA amine blend (30/70 wt. ratio, 25 phr) (376 mPa.s) necessary to give the best IPDA (23 phr) (433 mPa.s) properties. Castings of DGEBA resin cured only with IPDA at room temperature are very brittle and mechanical properties could not be measured. With JEFFAMINE® RFD-270 amines, however, good properties can be obtained with cures at lower temperatures or at room temperature. In blends with JEFFAMINE® D-230 and/or T-403 amine, IPDA levels of up to about 30 wt. % can be replaced with JEFFAMINE® RFD-270 amine containing blends. For other amine blends, the amount of JEFFAMINE® RFD-270 amine substitution will depend on the other components and the Tg desired for the system. 3

- 4. TOXICITY AND SAFETY For additional information on the toxicity and safe handling of this product, consult the Material Safety Data Sheet (Safety Data Sheet in Europe) prior to use of this product. HANDLING AND STORAGE Materials of Construction At temperatures of 75-100°F (34-38°C) Tanks Carbon steel Lines, valves Carbon steel Pumps Carbon steel Heat exchange Surfaces Stainless steel Hoses Stainless steel, polyethylene, polypropylene, and TEFLON® fluoropolymers Gaskets, packing Polypropylene or TEFLON® fluoropolymers (Elastomers such as neoprene, Buna N, and VITON® fluoroelastomers should be avoided) Atmosphere Nitrogen or dry air At temperatures above 100°F (38°C) Tanks Stainless steel or aluminum Lines, Valves Stainless steel Pumps Stainless steel or Carpenter 20 equivalent Atmosphere Nitrogen JEFFAMINE® RFD-270 amine may be stored under air at ambient temperatures for short periods. A nitrogen blanket is suggested for all storage, however, to reduce the effect of accidental exposure to high temperatures and to reduce the absorption of atmospheric moisture and carbon dioxide. It should be noted that pronounced discoloration is likely to occur at temperatures above 140°F (60°C), whatever the gaseous pad. Cleaning of line and equipment containing JEFFAMINE® RFD-270 amine can be accomplished using warm water and steam. In the event of spillage of this product, the area may be flushed with water. The proper method for disposal of waste material is by incineration with strict observance of all federal, state, and local regulations. AVAILABILITY JEFFAMINE® RFD-270 amine is available in 55-gallon (208 L) drums of 430 pounds (195 kg) net weight. Samples are available in North America and Asia by contacting our sample department at 1-800-662-0924. Samples in other locations, including Europe, are available by contacting any Huntsman Corporation sales office. 5300-0211 Copyright © 2010, 2011 Huntsman Corporation or an affiliate thereof. All rights reserved. JEFFAMINE, JEFFSOL and ARALDITE are registered trademarks of Huntsman Corporation or an affiliate thereof in one or more, but not all countries. VITON and TEFLON are registered trademarks or trademarks of E. I. du Pont de Nemours and Company or its affiliates. Huntsman Corporation warrants only that its products meet the specifications stated herein (if any). Typical properties, where stated, are to be considered as representative of current production and should not be treated as specifications. While all the information presented in this document is believed to be reliable and to represent the best available data on these products, HUNTSMAN MAKES NO WARRANTY OR GUARANTEE OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, NON-INFRINGEMENT OF ANY INTELLECTUAL PROPERTY RIGHT OF ANY THIRD PARTY, OR WARRANTIES AS TO QUALITY OR CORRESPENDENCE WITH PRIOR DESCRIPTION OR SAMPLE, AND ANY USER OF PRODUCTS DESCRIBED HEREIN SHOULD CONDUCT A SUFFICIENT INVESTIGATION TO ESTABLISH THE SUITABILITY OF ANY PRODUCT FOR ITS INTENDED USE AND ASSUMES ALL RISK AND LIABILITY WHATSOEVER RESULTING FROM THE USE OF SUCH PRODUCT, WHETHER USED SINGLY OR IN COMBINATION WITH OTHER SUBSTANCES. Product(s) described in this publication may be hazardous and/or toxic and require special precautions in handling. For all product(s) described herein, the user should obtain from Huntsman detailed information on hazards and/or toxicity, together with proper shipping, handling, and storage procedures, and should comply with all applicable safety and environmental standards. The behavior, hazards and/or toxicity of the product(s) referred to in this publication in manufacturing processes and their suitability in any given end-use environment are dependent upon various conditions such as chemical compatibility, temperature, and other variables, which may not be known to Huntsman. It is the sole responsibility of the user of such product(s) to evaluate the manufacturing circumstances and the final product(s) under actual end-use requirements and to adequately advise and warn future purchasers and users thereof. Main Offices US: Huntsman Corporation / 10003 Woodloch Forest Drive / The Woodlands, Texas 77380 / 281-719-6000 Technical Service US: 8600 Gosling Road / The Woodlands, Texas 77381 / 281-719-7780 Main Offices Europe: Huntsman Belgium BVBA / Everslaan 45 / B-3078 Everberg, Belgium / 32-2 -758-9211 Technical Service Europe: Technical Services Representative / Everberg Office / 32-2-758-9392 Main Offices Asia Pacific: Huntsman Singapore PTE / 150 Beach Road #37-00 Gateway West / Singapore 189720 / 65 6297 3363 Technical Service Asia Pacific: Huntsman Performance Products / 61 Market Road, Brooklyn, Victoria / Australia 3012 / 61 3 9933 6666 www.huntsman.com 4