2012 hino 155h series truck service repair manual

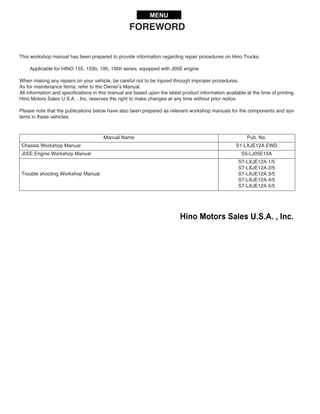

- 1. FOREWORD This workshop manual has been prepared to provide information regarding repair procedures on Hino Trucks. Applicable for HINO 155, 155h, 195, 195h series, equipped with J05E engine When making any repairs on your vehicle, be careful not to be injured through improper procedures. As for maintenance items, refer to the Owner's Manual. All information and specifications in this manual are based upon the latest product information available at the time of printing. Hino Motors Sales U.S.A. , Inc. reserves the right to make changes at any time without prior notice. Please note that the publications below have also been prepared as relevant workshop manuals for the components and sys- tems in these vehicles. Manual Name Pub. No. Chassis Workshop Manual S1-LXJE12A EWD J05E Engine Workshop Manual S5-LJ05E15A Trouble shooting Workshop Manual S7-LXJE12A 1/5 S7-LXJE12A 2/5 S7-LXJE12A 3/5 S7-LXJE12A 4/5 S7-LXJE12A 5/5 MENU

- 2. CHAPTER REFERENCES REGARDING THIS WORKSHOP MANUAL Use this chart to the appropriate chapter numbers for servicing your particular vehicle. CHAPTER MANUAL No. S1-LXJE12A (U.S.A.), S1-LXJE13A (CANADA) MODELS HINO 155, 155h, 195, 195h Production Code XFC710, XFC720, XFC730, XFC740, XJC700, XJC710, XJC720, XJC730, XJC740 GENERAL INTRODUCTION 1-001 HYBRID 3-001 TRANSMISSION 4-001 PROPELLER SHAFT 6-001 AXLE 7-001 DIFFERENTIAL 8-001 BRAKE 9-001 STEERING 10-001 SUSPENSION 11-001 FRAME AND FRAME ACCESSORY 12-001 CAB MOUNTING AND CAB SUSPENSION 13-001 BODY INSIDE ACCESSORY 15-001 BODY OUTSIDE ACCESSORY 16-001 AIR BAG AND SEAT BELT 17-001 HEATER AND AIR CONDITIONER 18-001 ELECTRICAL 19-001 CONTROL SYSTEM 20-001

- 3. ENGINE HYBRID TRANSMISSION CLUTCH PROPELLER SHAFT AXLE DIFFERENTIAL BRAKE STEERING FRAME AND FRAME ACCESSORY CAB MOUNTING AND CAB SUSPENSION BODY CONSTRUCTION INDEX: CHASSIS GROUP 1/2 SUSPENSION WORKSHOP MANUAL All rights reserved. This manual may not be reproduced or copied in whole in part, with- out the written consent of Hino Motors, Ltd. BODY INSIDE ACCESSORY BODY OUTSIDE ACCESSORY AIR BAG AND SEAT BELT HEATER AND AIR CONDITIONER GENERAL INTRODUCTION

- 4. ELECTRICAL INDEX: CHASSIS GROUP 2/2 CONTROL SYSTEM

- 5. WIRING DIAGRAM ACCORDING TO SYSTEM WIRE TO WIRE CONNECTOR JUNCTION CONNECTOR LOCATION RELAY LOCATION/FUSE AND RELAY BLOCK INDEX INDEX: CHASSIS GROUP WORKSHOP MANUAL All rights reserved. This manual may not be reproduced or copied in whole in part, with- out the written consent of Hino Motors, Ltd. GENERAL INTRODUCTION

- 6. GENERAL INTRODUCTION 1–1 1 GENERAL INTRODUCTION 1-001 HOW TO IDENTIFY VEHICLE TYPE .............. 1-2 HOW TO IDENTIFY VEHICLE TYPE...........................1-2 VEHICLE MODEL...................................................1-2 VEHICLE IDENTIFICATION NUMBER (VIN) STRUCTURE ..........................................................1-3 APPEARANCE OF VEHICLE ......................... 1-4 APPEARANCE.............................................................1-4 APPEARANCE OF VEHICLE .................................1-4 SAFETY INSTRUCTIONS AND READINESS TO WORK.............................................................. 1-5 WARNING ....................................................................1-5 GENERAL PRECAUTIONS ....................................1-5 IDENTIFICATION INFORMATION ..........................1-9 SAFETY INSTRUCTIONS FOR WORK.....................1-12 PRECAUTIONS ....................................................1-12 INTRODUCTION TO WORKSHOP MANUAL............1-16 GENERAL.............................................................1-16 INTRODUCTION TO DESCRIPTIONS.................1-17 DEFINITION OF TERM.........................................1-19 TIGHTENING OF BOLTS AND NUTS .......................1-20 BOLTS AND NUTS ...............................................1-20 PURPOSES OF TIGHTENING TORQUE.............1-20 CAUTIONS TO PREVENT LOOSENESS.............1-20 TYPES AND IDENTIFICATION.............................1-21 COMPATIBILITY (NO COMPATIBILITY IN BOLTS AND NUTS) ...................................................................1-22 STRENGTH CLASSES AND SYMBOLS..............1-23 PART No................................................................1-24 LIST OF TIGHTENING TORQUE .........................1-25 TIGHTENING OF FLARE NUTS AND HOSES ....1-27 HANDLING OF LIQUID GASKET..............................1-28 LIQUID GASKET...................................................1-28 GLOSSARY ................................................... 1-29 DEFINITION OF ABBREVIATION IN THIS MANUAL ....................................................................1-29 LIST OF ABBREVIATION .....................................1-29 GLOSSARY OF SAE AND HINO TERMS ............1-32 LUBRICANTS................................................ 1-35 LUBRICANTS.............................................................1-35 RECOMMENDED LUBRICANTS .........................1-35

- 7. GENERAL INTRODUCTION/HOW TO IDENTIFY VEHICLE TYPE1–2 HOW TO IDENTIFY VEHICLE TYPE HOW TO IDENTIFY VEHICLE TYPE VEHICLE MODEL EN01E01ZZZ010102001001 X J C 7 0 0 L H K T Q M A 3 CLASSIFICATIONREPORTED MODEL J05E-UG (HV)X X F J05E-TP (Diesel)J ENGINE MODEL C VEHICLE MODEL HEAVY DUTY TRUCK CAB WIDTH, DRIVE, FRAME FORM, WHEEL BASE 7 0 7 1 7 2 7 3 CAB WIDTH DRIVE WHEEL BASE FRAME ASSEMBLY WIDTH FRAME FORM WIDE 2WD MEDIUMOPEN WIDE 2WD LONGOPEN WIDE 2WD SUPER LONGOPEN WIDE 2WD SUPER LONGOPEN 840 mm {33 in.} 2,900 mm {114 in.} 3,500 mm {138 in.} 3,800 mm {150 in.} 4,100 mm {161 in.} 0 TYPE OF SUSPENSION FRONT RIGID, REAR RIGID CAB FORM BRAKE TYPE CAB FORM, BRAKE TYPE STEERING WHEEL POSITION L LEFT HAND DRIVE H Q SINGLE CAB VACUUM CREW CAB VACUUM C D K SINGLE CAB HYDRAULIC VACUUM HYDRAULIC CREW CAB SINGLE CAB CREW CAB HYDRAULIC DECK HEIGHT K HIGH FLOOR TRANSMISSION T 6AT DECK FORM 3 CHASSIS WITH CAB ENGINE HORSEPOWER, FUEL FUEL HORSEPOWER EXHAUST VERY HIGH US13 (13OBD)DIESEL OILM LOADING CAPACITY, GVW, REAR TIRES DESTINATION DESTINATION A U.S., CANADA 6.58 t {14,500 lbs} 8.14 t {17,950 lbs}, 8.85 t {19,500 lbs} Q T 7 4 WIDE 2WD SUPER LONGOPEN 4,400 mm {173 in.} REAR DOUBLE REAR DOUBLE L SHTS01ZZZ0100001

- 8. GENERAL INTRODUCTION/HOW TO IDENTIFY VEHICLE TYPE 1–3 VEHICLE IDENTIFICATION NUMBER (VIN) STRUCTURE EN01E01ZZZ010102001002 WMIVDSCDVIS (1)(2)(3)(4)(5)(6)(7)(8)(9)(10)(11)(12)(13)(14)(15)(16) JHHKDL2HXCK00100 (17) 1 MANUFACTURER,TYPE MODEL,CABTYPE, WHEELBASE, BRAKESYSTEM MODELYEARENGINEMODEL ASSEMBLYPLANTSERIES MAKE CHECKDIGIT SEQUENTIALNUMBER CODE JHNINCOMPLETEVEHICLE TYPEMANUFACTURER HINOMOTORS,LTD. 2AYINCOMPLETEVEHICLE HINOMOTORS CANADA,LTD. CODECODEYEARYEAR K2019 L2020 M2021 E2014 F2015 G2016 CODE PMHybrid APPLICATIONENGINEMODEL J05E-UG DMDieselJ05E-TP CODE ForUSA ForCanada 1 2 ASSEMBLYPLANT CODE CODE H MAKE SERIESGVWR HINO 6,580kg {14,500lbs.} 8,140-8,850kg {17,950-19,500lbs.} CODECLASSMODEL PRODUCTION CODE CABTYPEWHEELBASE BRAKE SYSTEM CODE 1 ASSEMBLYPLANT HINOMOTORS,LTD. HamuraPlantinJapanK HINOMOTORS,LTD. HamuraPlantinJapanK CanadaPlant(COE) N2022 P2023 H2017 J2018 R S T U V W X Y P H K L HINO195h HINO195 HINO195 HINO195 HINO155 HINO155 HINO155 HINO155 HINO195 HINO195 HINO155 HINO155 5 5 5 5 4 4 5 5 4 4 4 4 XFC710 HINO155hXFC720 HINO155hXFC740 HINO195hXFC720 HINO195hXFC740 HINO155hXFC710 HINO195hXFC720 HINO195hXFC740 HINO155hXFC740 HINO155hXFC720 HINO195XJC710 COE SINGLECAB COE SINGLECAB COE SINGLECAB COE SINGLECAB COE SINGLECAB COE SINGLECAB COE SINGLECAB COE SINGLECAB COE CREWCAB COE CREWCAB COE CREWCAB COE CREWCAB 3,500mm{138in.} 3,500mm{138in.} 2,900mm{114in.} 2,900mm{114in.} 3,800mm{150in.} 3,800mm{150in.} 3,800mm{150in.} 3,800mm{150in.} 4,400mm{173in.} 4,400mm{173in.} 4,400mm{173in.} 4,400mm{173in.} XJC700 XJC700 XJC710 XJC720 XJC740 XJC740 XJC720 XJC720 XJC740 XJC720 XJC740 HYDRAULIC G HINO195h 5 XFC730 HINO195XJC730 COE SINGLECAB 4,100mm{161in.}HYDRAULIC HYDRAULIC HYDRAULIC HYDRAULIC HYDRAULIC HYDRAULIC VACUUM VACUUM VACUUM VACUUM VACUUM VACUUM SHTS01ZZZ0100002

- 9. GENERAL INTRODUCTION/APPEARANCE OF VEHICLE1–4 APPEARANCE OF VEHICLE APPEARANCE APPEARANCE OF VEHICLE EN01E01ZZZ020102003001 SHTS01ZZZ0200001

- 10. GENERAL INTRODUCTION/SAFETY INSTRUCTIONS AND READINESS TO WORK 1–5 SAFETY INSTRUCTIONS AND READINESS TO WORK WARNING GENERAL PRECAUTIONS EN01E01ZZZ030101001001 Some recommended and standard maintenance services for your vehicle are included in this section. When performing maintenance on your vehicle be careful not to get injured by improper work. Improper or incomplete work can cause a mal- function of the vehicle which may result in personal injury and/or property damage. If you have any question about per- forming maintenance, please consult your Hino dealer. WARNING When working on your vehicle, observe the following general precautions to prevent death, personal injury and/ or property damage in addition to the particular DANGERS, WARNINGS, CAUTIONS and NOTICES in each chap- ter. • Always wear safety glasses or goggles to protect your eyes. • Remove rings, watches, ties, loose hanging jewelry and loose clothing before starting work on the vehicle. • Bind long hair securely behind the head. • When working on the vehicle, apply the parking brake firmly, place the gear shift lever in "Neutral" or "N" and block the wheels. • Always turn off the starter switch to stop the engine, unless the operation requires the engine running. Removing the key from the switch is recommended. • To avoid serious burns, keep yourself away from hot metal parts such as the engine, exhaust manifold, radia- tor, muffler, exhaust pipe and tail pipe. • Do not smoke while working on the vehicle since fuel, and gas from battery are flammable. • Take utmost care when working on the battery. It contains corrosive sulfuric acid. • Large electric current flows through the battery cable and starter cable. Be careful not to cause a short which can result in personal injury and/or property damage. • Read carefully and observe the instructions specified on the jack before using it. • Use safety stands to support the vehicle whenever you need to work under it. It is dangerous to work under a vehicle supported only by a jack. • If it is necessary to run the engine after the hood is raised (tilted), make sure that the parking brake is firmly applied, the wheels are blocked, and the gear shift lever is positioned in "Neutral" before staring the engine. • Run the engine only in a well-ventilated area to avoid inhalation of carbon monoxide. • Keep yourself, your clothing and your tools away from moving parts such as the cooling fan and V-belts when the engine is running. • Be careful not to damage lines and hoses by stepping or holding your feet on them. • Be careful not to leave any tool in the engine compartment. The tool may be hit by moving parts, which can cause personal injury.

- 11. GENERAL INTRODUCTION/SAFETY INSTRUCTIONS AND READINESS TO WORK1–6 PRECAUTIONS IN TILTING AND LOWERING THE CAB ! WARNING Be sure to observe the following when tilting and lowering the cab to reduce the risk of an accident which may result in death, serious injury and/or property damage. • Park the vehicle on a level place and ensure ample space around the cab before tilting the cab. • Apply the parking brake firmly and place the gearshift lever in “N” position (“P” position if your vehicle is equipped with automatic transmission). • Stop the engine and block the wheels. • Remove any articles in or over the cab and close the doors firmly. • Make sure there is no one in or around the cab and there are no obstacles in front of the vehicle or above the cab. • The catch (E), stopper (F), stay (G) and other parts such as the engine, radiator, and exhaust pipe can be very hot while your vehicle is operated. Be sure to confirm they have been cooled down before you start working under the cab. • Never raise or lower the cab only by yourself if your cab is equipped with heavy component such as a roof rack. • Never put your body under the cab while raising or lowering the cab. • Make sure the cab stopper stay is securely locked by the catch (E) and raise the stopper (F) to lock the catch (E) completely after raising the cab. • Before lowering the cab, make sure that any object such as hand tools, gloves or cloth are not left under the cab. • Make sure the handle (B) is caught by the catch after lowering the cab. Read the Owner’s manual for details. DEFINITION OF SAFETY TERMS Indicates an extremely hazardous situation if proper procedures are not followed and could result in death or serious injury. Indicates a potential hazardous situation if proper procedures are not followed and could result in death or serious injury. Indicates a hazardous situation if proper procedures are not followed and could result in serious injury or damage to parts/equipment. Indicates the need to follow proper procedures and to pay attention to precautions so that efficient service is provided. Provides additional information to help you to perform the repair efficiently. B F E G SHTS01ZZZ0300001

- 12. GENERAL INTRODUCTION/SAFETY INSTRUCTIONS AND READINESS TO WORK 1–7 TOWING • When being towed, always place the gear shift lever in "Neutral" and release the parking brake completely. In order to protect the bumper, fit a protection bar against the lower edge of the bumper and put a wood block under the frame near the No. 1 cross member when attaching the towing chain. Never lift or tow the vehicle if the chain is in direct contact with the bumper. 1. Towing procedures (1) Make sure that the propeller shaft of the vehicle to be towed is removed. When the differential gear or rear axle shaft is defective, remove both right and left rear axle shafts, then cover the hub opening to prevent loss of axle lubricant and entry of dirt or foreign matter. (2) Use a heavy duty cable or rope when towing the vehicle. Fasten the cable securely to the towing hook on the frame. (3) The angle of pulling direction of the cable fastened to the towing hook must not exceed 15° in horizontal and ver- tical directions from the straight ahead, level direction. Avoid using the hook in a way that subjects it to jerk, as in towing a vehicle trapped in a gutter. (4) Keep the gear shift lever in Neutral. (5) Make sure that the starter switch is kept in the "ON" position, if the engine is not running. (6) Make sure that the engine of the towed vehicle is kept running. If the engine is off, no compressed air/ no vac- uum will be available for the brake. This is dangerous, as the brake system does not function if the engine is not running. In addition, the power steering system will not function. The steering wheel, therefore, will become unusually hard to turn, making it impossible to control the vehicle. (7) Note that the engine brake and exhaust brake cannot be applied, if the propeller shaft is removed. (8) Make a slow start to minimize shock. Towing speed should be less than 30 km/h {18 mile/h}. 2. If the engine of the towed vehicle is defective, make sure that the vehicle is towed only by a tow truck designed for that purpose. (1) Front end towing (with front wheels raised off the ground) When towing from the front end with the front wheels raised off the ground, remove the rear axle shafts to protect the transmission and differential gears from being damaged. The hub openings should be covered to prevent the loss of axle lubricant or the entry of dirt or foreign matter. The above-mentioned precautions should be observed for vehicles equipped with either manual or automatic transmission, and for even short distance towing. After being towed, check and refill the rear axle housing with lubricant if necessary. (2) Rear end towing When being towed with the rear wheels raised off the ground, fasten and secure the steering wheel in a straight- ahead position.

- 13. HYBRID/HYBRID SYSTEM 3–11 SERVICE PLUG COMPONENT LOCATOR EN01E03ZZZ040402007001 Tightening torque Unit: Nm {kgfcm, lbfft} UNIT CHECK EN01E03ZZZ040402007002 INSPECTING THE SERVICE PLUG 1. INSPECTING THE SERVICE PLUG. (1) Using a circuit tester, measure the resistance value between service plug terminals. 1 Service plug 2 Service plug cover A 9 {92, 6.6} 1 2 A SHTS03ZZZ0400003 Inspection terminal Standard value 1-2 1 or less

- 14. HYBRID/HYBRID SYSTEM3–12 REPLACEMENT EN01E03ZZZ040402007003 REMOVING THE SERVICE PLUG 1. DISCONNECTING THE AUXILIARY BATTERY. (1) Disconnect the auxiliary battery negative terminal. 2. REMOVING THE SERVICE PLUG COVER. (1) Remove the bolts (4 pcs.) to remove the service plug cover. 3. REMOVING THE SERVICE PLUG. (1) Wear insulated gloves to remove the service plug from the HV battery assembly. ! CAUTION To prevent another engineer from reconnecting the service plug you disconnected, carry that plug around with you in your pocket. SHTS03ZZZ0400004 1 2 3 SHTS03ZZZ0400005

- 15. HYBRID/HYBRID SYSTEM 3–13 MOUNTING THE SERVICE PLUG 1. MOUNTING THE SERVICE PLUG. ! CAUTION Double check that you have not left any tools or parts inside before connecting the service plug, and double check the status of high-voltage connector tightening and the status of connector connections. (1) Wear insulated gloves to mount the service plug to the HV battery assembly. 2. MOUNTING THE SERVICE PLUG COVER. (1) Mount the service plug cover with the bolts (4 pcs.) Tightening Torque: 9 N·m {92 kgf·cm, 6.6 lbf·ft} 3. CONNECTING THE AUXILIARY BATTERY. (1) Connect the negative battery terminal of the auxiliary battery. 1 2 3 SHTS03ZZZ0400006 SHTS03ZZZ0400007

- 16. HYBRID/HYBRID SYSTEM3–14 PCU COMPONENT LOCATOR EN01E03ZZZ040402004001 Tightening torque Unit: Nm {kgfcm, lbfft} A 115 {1,173, 84.8} A A SHTS03ZZZ0400008

- 17. HYBRID/HYBRID SYSTEM 3–15 1 Service hole cover 3 Front panel 2 Clip 1 2 3 SHTS03ZZZ0400009

- 18. HYBRID/HYBRID SYSTEM3–16 Tightening torque Unit: Nm {kgfcm, lbfft} 1 Inverter terminal cover A 9 {92, 6.6} 1 A SHTS03ZZZ0400010

- 19. HYBRID/HYBRID SYSTEM 3–17 Tightening torque Unit: Nm {kgfcm, lbfft} 1 Motor cable A 7.2-10.8 {73-110, 5.3-8.0} B 9 {92, 6.6} A A B B 1 SHTS03ZZZ0400011

- 20. HYBRID/HYBRID SYSTEM3–18 REPLACEMENT EN01E03ZZZ040402004002 REMOVING THE PCU 1. DISCONNECTING THE AUXILIARY BATTERY. (1) Disconnect the auxiliary battery negative terminal. 2. REMOVING THE SERVICE PLUG. Reference: HYBRID, HYBRID SYSTEM, SERVICE PLUG, REPLACEMENT, REMOVING THE SERVICE PLUG (Page 3-12) 3. DISCONNECTING THE MOTOR CABLE AND 24V POWER CABLE. (1) Unfasten clips (4 pcs.) to remove the under cover service hole cover. (2) Remove the bolts (4 pcs.) and remove the inverter terminal cover. SHTS03ZZZ0400012 SHTS03ZZZ0400013

- 21. HYBRID/HYBRID SYSTEM 3–19 (3) Remove bolts (6 pcs.) and detach the motor cable. 4. DISCONNECTING THE CONNECTOR. (1) Unfasten the clips (2 pcs.) and remove the front panel. (2) Disconnect the connectors (2 locations). TERMINAL SIDE CABLE SIDE SHTS03ZZZ0400014 SHTS03ZZZ0400015 SHTS03ZZZ0400016

- 22. HYBRID/HYBRID SYSTEM3–20 5. REMOVING THE PCU. (1) Set the engine lifter on the PCU. (2) Remove the nuts (6 pcs.) to remove the PCU. SHTS03ZZZ0400017

- 23. HYBRID/HYBRID SYSTEM 3–21 MOUNTING THE PCU 1. MOUNTING THE PCU. (1) Set the engine lifter on the PCU. (2) Mount the PCU using the nuts (6 pcs.). Tightening Torque: 115 N·m {1,173 kgf·cm, 84.8 lbf·ft} 2. CONNECTING THE CONNECTOR. (1) Connect the connectors (2 locations). (2) Mount the front panel using the clips (2 pcs.). SHTS03ZZZ0400018 SHTS03ZZZ0400019 SHTS03ZZZ0400020

- 24. HYBRID/HYBRID SYSTEM3–22 3. CONNECTING THE MOTOR CABLE AND 24V POWER CABLE. (1) Connect the motor cable using bolts (6 pcs.). Tightening Torque: 9 N·m {92 kgf·cm, 6.6 lbf·ft} (Cable side) 7.2-10.8 N·m {73-110 kgf·cm, 5.3-8.0 lbf·ft} (Terminal side) (2) Mount the inverter terminal cover with the bolts (4 pcs.) Tightening Torque: 9 N·m {92 kgf·cm, 6.6 lbf·ft} (3) Fasten clips (4 pcs.) to mount the under cover service hole cover. 4. MOUNTING THE SERVICE PLUG. Reference: HYBRID, HYBRID SYSTEM, SERVICE PLUG, REPLACEMENT, MOUNTING THE SERVICE PLUG (Page 3-13) 5. CONNECTING THE AUXILIARY BATTERY. (1) Connect the negative battery terminal of the auxiliary battery. TERMINAL SIDE CABLE SIDE SHTS03ZZZ0400021 SHTS03ZZZ0400022 SHTS03ZZZ0400023

- 25. HYBRID/HYBRID SYSTEM 3–23 HV BATTERY COMPONENT LOCATOR EN01E03ZZZ040402003001 *: Nonreusable part Tightening torque Unit: Nm {kgfcm, lbfft} 1 HV battery 3 Under cover 2 Clip* 4 Clip A 31 {316, 22.9} B 13 {133, 9.6} 1 2 2 2 3 4 4 A A A A B SHTS03ZZZ0400024

- 26. HYBRID/HYBRID SYSTEM3–24 Tightening torque Unit: Nm {kgfcm, lbfft} 1 Terminal cover A 9 {92, 6.6} 1 A SHTS03ZZZ0400025

- 27. Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL. NO WAITING NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it.

- 28. HYBRID/HYBRID SYSTEM 3–25 REPLACEMENT EN01E03ZZZ040402003002 REMOVING THE HV BATTERY ASSEMBLY 1. REMOVING THE PCU Reference: HYBRID, HYBRID SYSTEM, PCU, REPLACEMENT, REMOVING THE PCU (Page 3-18) 2. DISCONNECTING THE HARNESS. (1) Disconnect the connector clamp and connector. (2) Unfasten the nuts (4 pcs.) and remove the terminal cover. (3) Unfasten the nuts (2 pcs.) to disconnect the harness. (4) Disconnect the hose clamp of the snorkel hose. (5) Disconnect the grommets (3 locations). SHTS03ZZZ0400026 SHTS03ZZZ0400027 SHTS03ZZZ0400028

- 29. HYBRID/HYBRID SYSTEM3–26 3. REMOVING THE UNDER COVER. (1) Remove the bolts (3 pcs.) and clips (10 pcs.). (2) Pull the under cover to the front, and remove the clips (5 pcs.) and under cover. NOTICE Clips (5 pcs.) inside the under cover are not reusable. 4. REMOVING THE BOTTOM OF PCU. (1) Unfasten the bolts (10 pcs.) and remove the bottom of PCU. NOTICE • Be careful not to get the check valve at the bottom of the HV bat- tery assembly caught on anything or do not remove it. • While taking care not to damage the check valve, place the HV battery assembly on a bench as shown in the figure. UNDER COVER SHTS03ZZZ0400029 HV BATTERY ASSEMBLY PCU LOWER SHTS03ZZZ0400030 CHECK VALVE SHTS03ZZZ0400031 CHECK VALVE BENCH SHTS03ZZZ0400032

- 30. HYBRID/HYBRID SYSTEM 3–27 5. REMOVING THE HV BATTERY COOLING FAN. Reference: HYBRID, HYBRID SYSTEM, HV BATTERY COOL- ING FAN, REPLACEMENT, REMOVING THE HV BATTERY COOLING FAN (Page 3-32) 6. REMOVING THE HV BATTERY ECU. Reference: HYBRID, HYBRID SYSTEM, HV BATTERY ECU, REPLACEMENT, REMOVING THE HV BATTERY ECU (Page 3- 36) 7. REMOVING THE SYSTEM MAIN RELAY JUNCTION BLOCK. Reference: HYBRID, HYBRID SYSTEM, SYSTEM MAIN RELAY JUNCTION BLOCK, REPLACEMENT, REMOVING THE SYS- TEM MAIN RELAY JUNCTION BLOCK (Page 3-40)

- 31. HYBRID/HYBRID SYSTEM3–28 MOUNTING THE HV BATTERY ASSEMBLY 1. MOUNTING THE SYSTEM MAIN RELAY JUNCTION BLOCK. Reference: HYBRID, HYBRID SYSTEM, SYSTEM MAIN RELAY JUNCTION BLOCK, REPLACEMENT, MOUNTING THE SYS- TEM MAIN RELAY JUNCTION BLOCK (Page 3-41) 2. MOUNTING THE HV BATTERY ECU. Reference: HYBRID, HYBRID SYSTEM, HV BATTERY ECU, REPLACEMENT, MOUNTING THE HV BATTERY ECU (Page 3- 38) 3. MOUNTING THE HV BATTERY COOLING FAN. Reference: HYBRID, HYBRID SYSTEM, HV BATTERY COOL- ING FAN, REPLACEMENT, MOUNTING THE HV BATTERY COOLING FAN (Page 3-33) 4. MOUNTING THE BOTTOM OF PCU. (1) Mount the bottom of PCU with the bolts (10 pcs.). Tightening Torque: 31 N·m {316 kgf·cm, 22.9 lbf·ft} NOTICE Fasten the bolts beginning with reference bolt (A). 5. MOUNTING THE UNDER COVER. (1) Mount the under cover using new clips (5 pcs.). (2) Mount the bolts (3 pcs.) and clips (10 pcs.). Tightening Torque: 13 N·m {133 kgf·cm, 9.6 lbf·ft} 6. CONNECTING THE HARNESS. (1) Connect the grommets (3 locations). (2) Connect the harness using the nuts (2 pcs.). Tightening Torque: 7.2-10.8 N·m {73-110 kgf·cm, 5.3-8.0 lbf·ft} (3) Connect the snorkel hose with clamp. HV BATTERY ASSEMBLY PCU LOWER REFERENCE BOLT (A) SHTS03ZZZ0400033 UNDER COVER SHTS03ZZZ0400034 SHTS03ZZZ0400035

- 32. HYBRID/HYBRID SYSTEM 3–29 (4) Mount the terminal cover with the nuts (4 pcs.). Tightening Torque: 9 N·m {92 kgf·cm, 6.6 lbf·ft} (5) Connect the connector clamp and connector. 7. MOUNTING THE PCU. Reference: HYBRID, HYBRID SYSTEM, PCU, REPLACEMENT, MOUNTING THE PCU (Page 3-21) SHTS03ZZZ0400036 SHTS03ZZZ0400037