Textile Fiber & Yarn

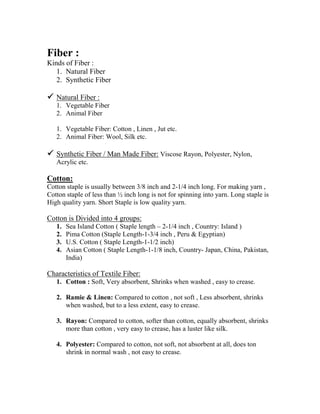

- 1. Fiber : Kinds of Fiber : 1. Natural Fiber 2. Synthetic Fiber Natural Fiber : 1. Vegetable Fiber 2. Animal Fiber 1. Vegetable Fiber: Cotton , Linen , Jut etc. 2. Animal Fiber: Wool, Silk etc. Synthetic Fiber / Man Made Fiber: Viscose Rayon, Polyester, Nylon, Acrylic etc. Cotton: Cotton staple is usually between 3/8 inch and 2-1/4 inch long. For making yarn , Cotton staple of less than ½ inch long is not for spinning into yarn. Long staple is High quality yarn. Short Staple is low quality yarn. Cotton is Divided into 4 groups: 1. Sea Island Cotton ( Staple length – 2-1/4 inch , Country: Island ) 2. Pima Cotton (Staple Length-1-3/4 inch , Peru & Egyptian) 3. U.S. Cotton ( Staple Length-1-1/2 inch) 4. Asian Cotton ( Staple Length-1-1/8 inch, Country- Japan, China, Pakistan, India) Characteristics of Textile Fiber: 1. Cotton : Soft, Very absorbent, Shrinks when washed , easy to crease. 2. Ramie & Linen: Compared to cotton , not soft , Less absorbent, shrinks when washed, but to a less extent, easy to crease. 3. Rayon: Compared to cotton, softer than cotton, equally absorbent, shrinks more than cotton , very easy to crease, has a luster like silk. 4. Polyester: Compared to cotton, not soft, not absorbent at all, does ton shrink in normal wash , not easy to crease.

- 2. 5. Wool: Compared to cotton, not very soft, not absorbent. The staple is slightly crimpy which can lead to a bulky effect when finally made into a fabric. It shrinks seriously when washed in hot water. Not easy to crease. 6. Nylon: Can be soft or firm dependent on the finish applied, not absorbent, does not shrink when washed, not easy to crease, very strong. 7. Silk: Finer and softer than cotton , equally absorbent, shrinks more than cotton easy to crease , has a smooth surface with luster when it is made into fabric. 8. Acrylic: Not soft, not absorbent, does not shrink in normal wash. The staple is slightly crimpy which can make the final product, the fabric, bulky or beefy, not easy to crease. Yarn: 1. Spun yarn 2. Filament Yarn Ring Spun yarn : Spun yarn is spun by spindles it is called ring spun yarn. 20/2 – 20 count 2 ply 20/3 – 20 count 3 ply 60 / 4 – 60 count 4 ply Carded Yarn : Without combing produced the carded yarn . Such as: 3s, 40s , 60s etc. Combed yarn: Produced the yarn with combing process. Cost is high. Such as: 76s Rotor yarn : Produced the lower count yarn. Such as: 7s to 20s . Filament yarn: 70 Denier. OE yarn ( open end yarn) : OE yarn is spun by means by air current and not by spindles. Polyester Cotton Blended: In the trade , we call this blend, “TC”. TC stands for Tetron & Cotton. Tetoron is also Called Polyester. “ TC” Fabric usually means 65% Polyester, 35% cotton, but strictly speaking it means 51% or more of polyester with balance in cotton.

- 3. Other Blended: Polyester-Wool Acrylic –Wool Polyester-Rayon Silk – cotton Rayon-cotton T-R-C (Polyester, rayon & cotton) Popular Textile yarn Sizes: Most Popular Sizes Less Popular sizes Cotton Cotton TC/CVC TC/CVC 6s 7s 8s 8s 10s 10s 12s 13s 14s 14s 16s 16s 17s 20s 20s 21s 21s 24s 24s 30s 30s 32s 32s 33s 40s 42s

- 4. 45s 60s 60s Flow chart of Carded Yarn: Blow Room ………………………………………….Lap Carding ………………………………… ……….Carded Sliver Pre comb Drawing Frame …………………….Drawing sliver /drawn sliver Post comb Drawing Frame …………………….Drawing sliver /drawn sliver Speed Frame / Simplex …………………………Roving Ring Frame ……………………………………..Yarn (ring bobbin) Winding ………………………………………. Cone or other Package Reeling………………………………………….Hank Bundling ……………………………………….Bundle Baling …………………………………………..Bale Yarn in Hank Form ……………………………..Finished Hank bale Flow chart of Carded Yarn: Blow Room ………………………………………….Lap Carding ………………………………… ……….Carded Sliver

- 5. Pre comb Drawing Frame …………………….Drawing sliver /drawn sliver Lap former ……………………………………….Mini Lap Combing ………………………………………….Combed sliver Post comb Drawing Frame …………………….Drawing sliver /drawn sliver Speed Frame / Simplex …………………………Roving Ring Frame ……………………………………..Yarn (ring bobbin) Winding ………………………………………. Cone or other Package Reeling………………………………………….Hank Bundling ……………………………………….Bundle Baling …………………………………………..Bale Yarn in Hank Form ……………………………..Finished Hank bale Price of Cotton & Cotton Mixed Yarn : SL. Yarn Count Price $ /Lbs 01 100% Cotton (Carded) 2/20 “NE” 2.10/ Lbs 02 100% Cotton ( Combed 2/20 “NE” 2.40/ Lbs with soft Quality) 03 100% Cotton (Carded) 2/30, 2/32 “NE” 2.45/ Lbs 04 100% Cotton ( Combed) 2/30 “NE” 2.65/ Lbs 05 100% Cotton ( Combed) 2/32 “NE” 2.60/ Lbs 06 100% Cotton ( Combed) 2/40 “NE” 3.60/ Lbs 07 100% Cotton SLUB Yarn 2/32 “NE” 3.60/ Lbs 08 50% Cotton 50% Acrylic 2/20 “NE” 2.75/ Lbs 09 50% Cotton 50% Acrylic 2/30 “NE” 3.00/ Lbs 10 55% Cotton 45% Acrylic 2/20 “NE” 2.90/ Lbs 11 55% Cotton 45% Acrylic 2/30 “NE” 3.25/ Lbs 12 60% Cotton 40% Acrylic 2/16 ‘s 3.00/ Lbs

- 6. (Roving yarn ) 13 60% Cotton 40% Acrylic 2/16 ‘s 3.10/ Lbs (Roving yarn ) 14 60% Cotton 40% Acrylic 2/16 ‘s 2.90/ Lbs 15 80% Cotton 20% Wool 2/32 Nm Not Available 16 100% Cotton mélange 2/20 & 2/32 “NE” Not Available Viscose Rayon: SL. Yarn Count Price $ /Lbs 01 100% Viscose Rayon 2/30 “NM” 2.80 /Lbs 02 70% Viscose Rayon 30% 2/30 “NM” 3.60 / Lbs Acrylic (Solid & mélange ) Nylon / Spandex / Lacra : Yarn Count Price $ /Lbs 01 Nylon / Spandex / Lacra 70% / 20% 4.60 /Lbs 02 100% Nylon / Polimaed 70 D/2 (Double) 3.70 /Lbs 03 100% Nylon / Polimaed 70 D/1 (Single) 3.90 /Lbs Price Quotation of Knit Yarn From: BF Textiles Ltd. Dhaka , Bangladesh Sub : Price Quotation for Knit Yarn. Dear Sir, We would like to give very special offer for you, please give us the order so that we can arrange as per your requirement. Please find below the price. SL/no Description of Yarn Price in US$ 01 24/1-26/1 Carded 100% cotton auto cone $3.55 Yarn Usterized and Electronically cleaned.

- 7. 02 28/1-30/1 Carded 100% cotton auto cone $3.60 Yarn Usterized and Electronically cleaned. 03 32/1 Carded 100% cotton auto cone Yarn $3.70 Usterized and Electronically cleaned. 04 34/1 Carded 100% cotton auto cone Yarn $3.80 Usterized and Electronically cleaned. 05 36/1 Carded 100% cotton auto cone Yarn $3.90 Usterized and Electronically cleaned. 06 40/1 Carded 100% cotton auto cone Yarn $4.10 Usterized and Electronically cleaned. Offer Validity: This offer is valid up to: 01.01.2011 We hope, your honor would find our offer suitable and favor us with your valued order. Your kind Cooperation will be highly appreciated Thanking you. Senior Executive Business Development BF Textile Ltd. Cell: 01725-425906 Email: ………….. Measurement of Yarn Count: We have followed a different way to find out the count of the yarn. At first we unravel a considerable no yarn form the fabric. Then we measured the total length of the yarn and measured the weight of that no of yarn. From these weights, we find out the Count of the yarn. The equation we followed is as follow: Count = (N x L x 453.6 ) / ( Wt. x 36 x 840) Where, N = number of yarn in bundle L = length of yarn Wt. = weight of yarn.

- 8. Another formula is the following : GSM = (Ks x Tex ) / Stitch length (mm ) Where, Ks is a constant. Its value is different for different fabric structure and fabric type. Ks is calculated and estimated as below: Ks = ( GSM x Stitch length) / Tex Fabric Type Color Value of Ks Single Jersey Average 19.55 Single lacoste Average 22.4 Double Lacoste Average 22.75 Polo pique Average 25 Plain Interlock Average 39.3 1 x 1 Rib Average 24.5 1 x 1 Rib Average 26.5 2 x 1 Rib Average 28.3 Flat back Rib - 81 3 Thread fleece - 40.92 Yarn count numbering system : Yarn Count conversion Unit Symbols Type Constant Unit Ne, NeC, 840 Cotton Count fixed weight 1 pound NeB yards Tex TEX, T fixed length 1,000 meter 1 gram 1,000 Metric Count Nm fixed weight 1,000 gram meter 333 Metric Ticket Tkt fixed weight 1,000 gram meter Denier Td, d fixed length 9,000 meter 1 gram 300 Linen Count NeL fixed weight 1 pound yards 256 Wool Count NeW fixed weight 1 pound yards

- 9. fixed weight, Silk Machine A=900 yards, 100 1 ounce Twist B=800 yards, yards F=300 yards, etc. Some Common Yarn Count. List of some most used yarn count The following counts of yarn that are widely used for knitting process are given: YARN COUNT: a) Cotton: 20/1, 24/1, 26/1, 28/1, 30/1, 34/1, 40/1 Ne. b) Terylene cotton: 20/1, 24/1, 26/1, 28/1, 30/1 Ne. c) CVC: 26/1, 28/1, 30/1, 34/1 Ne. d) Melange: 20/1, 22/1, 26/1, 30/1 Ne. e) Spandex: 20D, 40D, 70D. f) Polyester: 75D, 150D. g) Sewing thread: 50/2, 40/2, 75D, 150D etc. Basic knowledge of knit Fabric 1. Plain /Single/Jersey knit: People call it jersey knit . a weft knit process producing a plain , flat surfaced knitted fabric formed with a distinct face and back. Smooth side are called Face. Produced T-shirt, under-wear, sports wear etc by Single jersey fabric. 2. Interlock Fabric: A weft knit process producing a compound fabric. It is less elasticity fabric. Actually it is Double faced knitted fabric which face &

- 10. Back side looks same and smooth. Produced Polo-Shirt , T-shirt , under- wear by Interlock fabric. 3. Rib Fabric: A weft knit process producing a double faced fabric. Distinct effect looks at lengthwise and more elasticity in fabric width. Examples: 1x1 rib, 2x 1 rib, 2x 2 rib , 3x1 rib , 3 x 3 rib , 5 x 2 rib etc. Produced T- shirt, Polo-shirt by Rib fabric. 4. Fleece Fabric: One side looks like Jersey , the other side heavely brushed. 5. Flat knit: Flat knit is a weft knit fabric but do not produced tube fabric as circular knitting. Produced the knit collar , Cuff etc. 6. Yarn Dyed fabric: At first , dyeing the yarn then produced the fabric by color yarn that is called yarn dyed fabric. 7. Piece dyed fabric: when produced the fabric by Natural color yarn that is called Raw Fabric. For produced the Piece dyed fabric at first bleaching the raw fabric then dyeing .so that is called Piece dyed or Solid dyed fabric. 8. Feeder Stripe: More color yarns are used in the Feeder stripe but Repeat size will be 2 inch. 9. Engineering stripe: More color yarns are used in the Feeder stripe but Repeat size are not fixed. TC Fabric / PC Fabric Analysis: Polyester Cotton Warp (TC) = 65% 35 % Weft 100% Cotton = 100% 0% Total = 165% 35% 165% divided by 2 = 82.5% Polyester 35 divided by 2 = 17.5% cotton Therefore, The fabric is TC 82.5% polyester , 17.5% cotton. However , if you change the weft from 100% polyester to 100% cotton, then this fabric is CVC. See following calculation:

- 11. Polyester Cotton Warp (TC) = 65% 35 % Weft 100% Cotton = 0% 100% Total = 65% 135% 65% divided by 2 = 32.5% Polyester 135 divided by 2 = 67.5% cotton Therefore, The fabric is CVC 32.5% polyester , 67.5% cotton. Fabric , GSM, & Yarn Count Fabric Name Weight /GSM Yarn Count Single Jersey 200-230 20s Single Jersey 180-190 24s Single Jersey 165-175 26s Single Jersey 150/155-165 28s Single Jersey 135-145 30s Single Jersey 125-135 32s Fabric Name Weight / GSM Yarn Count Pique 235-240 24s Pique 220-225 26s Pique 190-210 28s Pique 180-190 30s Pique 160-170 32s Fabric Name Weight / GSM Yarn Count Interlock Fabric 260-270 30s Interlock Fabric 240-250 32s Interlock Fabric 220-230 34s Interlock Fabric 200-210 36s Interlock Fabric 190-200 40s Fabric Name Weight / GSM Yarn Count Rib Fabric 280-300 20s

- 12. Rib Fabric 240-260 24s Rib Fabric 220-230 26s Rib Fabric 200-210/215 28s Rib Fabric 180-200 30s Rib Fabric 160-180 32s Fabric Name Weight / GSM Yarn Count Fleece Fabric 310 26/20s Fleece Fabric 280 30/16s Fleece Fabric 260 30/24s Fleece Fabric 240 30/26s Fabric knitting cost Sl. Machine Yarn Knitting charge Fabric Type No. Gauge Count Per Kg in Taka 20/s- 1 Single Jersey (M/C Dia 19-38) 24 10 30/s 20/s- 2 Single Jersey (M/C Dia 40-48) 24 11 30/s 26/s- 3 Single Jersey 28 13 30/s 34/s- 4 Single Jersey 24 14-16 40/s 16/s- 5 Single Jersey 20 16-25 18/s 6 Single Jersey Slub Yarn 24 15-20 7 Single Jersey Slub Yarn 20 18-20 S/J D/Yarn F/ Stripe(M/C Dia 8 24 20-30 18-40) S/J D/Yarn F/ Stripe(M/C Dia 9 24 28-30 42-48) S/J D/Yarn F/ Stripe(M/C Dia 10 20 25-30 18-40) S/J D/Yarn F/ Stripe(M/C Dia 11 20 35-40 42-48) 40/2- 12 Heavy Jersey (2 ply) 20 15-18 26/2 30/s- 13 Half Feeder Lycra S/Jersey 24 22-24 40/s

- 13. H.F.Lycra S/J Yarn Dyed Stripe 14 24 30-35 (M/C Dia 18-40) H.F.Lycra S/J Yarn Dyed Stripe 15 24 40-45 (M/C Dia 42-48) 30/s- 16 Full Feeder Lycra S/Jersey 24/28 28 34/s 36/s- 17 Full Feeder Lycra S/Jersey 24/28 30 40/s F.F.Lycra S/J Yarn Dyed Stripe 18 24 38-40 (M/C Dia 18-40) F.F.Lycra S/J Yarn Dyed Stripe 19 24 48-50 (M/C Dia 42-48) 30/s- 20 P.K / Lacost 24 15 24/s 30/s- 21 P.K / Lacost 20 18 20/s 34/s- 22 P.K / Lacost 28 20 26/s 23 P.K F/Stripe (M/C Dia 18-40) 24 25-30 24 P.K F/Stripe (M/C Dia 18-40) 20 30-35 25 P.K F/Stripe (M/C Dia 42-48) 24 30-40 26 P.K F/Stripe (M/C Dia 42-48) 20 45-50 30/s- 27 1X1 Normal RIB 18 15 20/s 32/s- 28 1X1 Normal RIB 18 18 36/s 30/s- 29 Yarn Dyed (1X1) Stripe Rib 18 25-30 20/s 30/s- 30 Lycra RIB (Half Feeder) 18 25-30 26/s 30/s- 31 Lycra RIB (Full Feeder) 18 35-40 40/s 30/s- 32 (2X1) RIB 18 25-28 20/s 30/s- 33 (2X2) RIB 18 28-30 20/s 30/s- 34 (2X1) H. Feeder Lycra Rib 18 35 24/s 30/s- 35 (2X1) H. Feeder Lycra Rib 18 45 24/s 36 Plain Interlock 22/24 UP TO 18

- 14. 32/s 34/s- 37 Plain Interlock 22/24 20 40/s 40/s- 38 Plain Interlock 28 28-36 50/s 39 Interlock Feeder Stripe 24 35-40 40 Interlock H.F Ly. Attachement 24 35-40 30/s- 41 Interlock D / Needle 24 25-30 40/s 42 Mash/Flat Back Rib 60-80 Three Thread Fleece (French 43 18 Terry) 44 Cross Terry 20-22 Three Thread Lycra Fleece ( 45 35-40 French Terry) 46 Two Thread Fleece 20-22 47 Two Thread Lycra Terry 35-40 48 Engineering Stripe (4 Color) S/J 24 100-110 49 Engineering Stripe (6 Color) S/J 24 120-130 50 Engineering Stripe 2Ply 20 130-150 51 Engineering Stripe 2Ply 16 160-170 Engineering Stripe (4 Color) 52 24 120-125 P.K/Lacost Engineering Stripe (6 Color) 53 24 130-140 P.K/Lacost Eng. Stripe (4&6 Color) (H/ 54 24 220-230 Feeder Lycra S/J.P.K) Eng. Stripe (4&6 Color) (F/ 55 24 240-250 Feeder Lycra S/J.P.K) 56 Eng. Stripe Flat Back Rib 300 57 Eng. Stripe Terry 24/20 180-220 Engineering Stripe (6 Color) 58 170-180 RIB Engineering Stripe (6 Color) 59 180-190 Interlock Engineering Stripe (6 Color) 60 250-300 Lycra RIB / Interlock Engineering Stripe 2X1 F. 61 350-400 Feeder Lycra Rib Engineering Stripe 2X1 H. 62 350 Feeder Lycra Rib

- 15. 63 Pointal Rib (Normal) 70-100