Brewing of a lager beer

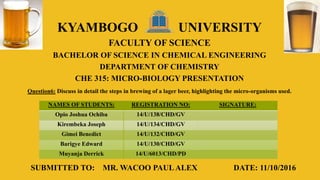

- 1. KYAMBOGO UNIVERSITY FACULTY OF SCIENCE BACHELOR OF SCIENCE IN CHEMICAL ENGINEERING DEPARTMENT OF CHEMISTRY CHE 315: MICRO-BIOLOGY PRESENTATION Question6: Discuss in detail the steps in brewing of a lager beer, highlighting the micro-organisms used. NAMES OF STUDENTS: REGISTRATION NO: SIGNATURE: Opio Joshua Ochiba 14/U/138/CHD/GV Kirembeka Joseph 14/U/134/CHD/GV Gimei Benedict 14/U/132/CHD/GV Barigye Edward 14/U/130/CHD/GV Muyanja Derrick 14/U/6013/CHD/PD SUBMITTED TO: MR. WACOO PAULALEX DATE: 11/10/2016

- 2. Brewing is the production of beer by steeping a starch source (commonly cereal grains, the most popular of which is barley) in water and fermenting the resulting sweet liquid with yeast. BARLEY – the body & soul of beer YEAST – the life of beer HOPS – the spice of beer WATER – the integrity & purity of beer

- 4. Malting is the process where barley grain is made ready for brewing. A. Selection of barley B. Germination (Done by steeping) C. Kilning D. Milling Maximize Enzyme Synthesis To Stabilize and Preserve Enzyme Activity Well.

- 5. Malt is sprouted barley. Barley is soaked in water to begin the process of germination, then dried and toasted for flavor. Malting produces an enzyme, diastase, which turns starch into sugar.

- 6. • Two row barley (Mostly used) • Six row Barley Germination is done by steeping the barley in cold water at 10-200C for 2 or 3 days The Germination is accomplished by the synthesis of myriad-enzymes. The barley reaches its maximum enzyme activity when the rootlets reach a length of one-third of the size of the grain. Barley is dried with a temperature range of 45-600C to stop further germination, stabilize and preserve enzyme activity. Milling breaks the kernels apart and exposes the cotyledon, which contains starches, proteins and enzymes.

- 7. Mashing is the process of combining a mixture of milled malt with water, and heating this mixture in a vessel called a "mash tun". To activate the Malt Enzymes Naturally occurring enzymes convert starch into fermentable sugars (Saccharification)

- 8. The brewing water should have medium hardness The pH should be between 6 and 7. The mash (malt water mixture) is gradually heated from 200C to 600C to 650C by infusion, decoction or combination of the two, to extract as much sugar as possible from the grain.

- 9. Lautering is the separation of the liquid containing the sugar extracted during mashing from the grains. The extracted liquid is the “wort”. The temperature of the mash is raised to 760C which effectively inactivates all enzyme activity. The main component of wort other than water is carbohydrate in form of small fermentable sugars, the rest are carbohydrate fractions of longer non-fermentable oligosaccharides that include dextrins. The final PH of the wort is around 5.2.

- 10. In the final step prior to fermentation, the wort is moved into a large tank known as a brew kettle where it is boiled with hops. Hops provide two (2) main characteristics to beer namely; flavour and aroma. Hops also enhance preservation and increase shelf life of beer.

- 11. 1) It kills all the micro-organisms remaining after mashing, making the wort, sterile. 2) Inactivates most of the enzymes still after the mashing or reduces their activity to barely detectible levels. 3) Enhances extraction of oils and resins from the hops and accelerates isomerization of hop acids. 4) Proteins, tannins, and other materials precipitate during the boiling step. 5) Enhances colour development by catalyzing formation of Maillad reaction products. 6) Undesirable volatile components such as Sulphur containing aroma compounds are removed. 7) Prolonged boiling causes evaporation of water and concentration of the wort.

- 12. The fermentation of the wort occurs in ferment vessels of varying, size and configuration, and in either batch or continuous modes. Lager fermentation vessels are typically cylindric, with cone-shaped bottoms (cylindroconical), so that when the yeasts flocculate and settle, the cells collect within the conical region.

- 13. After the wort is cooled and aerated, the yeast culture is, at last, added to the wort, in a step called pitching. Lager beers are fermented by Saccharomyces pastorianus also known as the “lager” or “bottom-fermenting” yeast. In contrast, when lager yeasts flocculate, the flocks sediment to the bottom. Larger style beers are fermented by yeast capable of growing at temperatures below 150C. LAGER!!

- 14. For lager beers, Conditioning or lagering occurs in tanks held at lower temperatures for a longer time. Typically, temperatures as low as 00C, for as long as three months, can be used. Lagering matures the beer & mallows its flavour. The CO2 that evolves is trapped, and the beer becomes naturally carbonated.

- 15. After conditioning by lagering, clarification is done to remove any suspended yeast cells and other micro-organisms that are still be present. Clarification can occur via physical separation methods such as centrifugation or by addition of fining agents. Fining agents act by promoting flocculation of yeast cells and include wood chips, gelatin, and isin glass. Several filtration configurations exist including plate and frame systems, leaf filters, cartridge filters and membrane filtration.

- 16. Carbonation provides sensual appeal by enhancing mouth feel, flavour, body and form. Carbondioxide preserves the beer by reducing the PH and the redox potential such that various aerobic, acid sensitive spoilage organisms are inhibited. Carbonation of beer can occur naturally via secondary fermentation or mechanically by directly adding carbondioxide after the condition and clarification steps.

- 17. The simplest form of packaging is to feel the beer directly into cans or glass bottles. The packaging steps are performed under aseptic conditions to prevent post processing contamination. Sterile nitrogen or carbondioxide can be used to flash the environment and sterile water used to ensure that the relevant equipments, especially the areas around the fillers remain free of microbial contaminants. After packaging, beer is heat pasteurized. Lager beer is always processed via tunnel pasteurization systems in which filled and sealed bottles or cans are heated by hot water. Pasteurizing the beer after it is already in sealed packages prevents post pasteurization contamination.

- 18. ANY QUESTIONS ?? Drink & Serve Responsibly THE END!!!