Qm0012 statistical process control and process capability

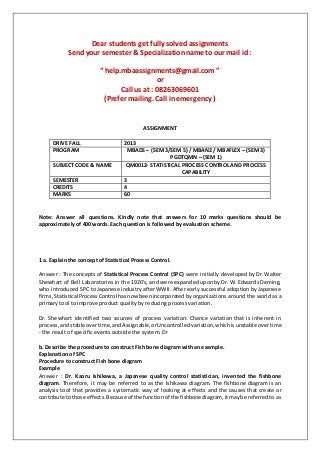

- 1. Dear students get fully solved assignments Send your semester & Specialization name to our mail id : “ help.mbaassignments@gmail.com ” or Call us at : 08263069601 (Prefer mailing. Call in emergency ) ASSIGNMENT DRIVE FALL 2013 PROGRAM MBADS – (SEM 3/SEM 5) / MBAN2 / MBAFLEX – (SEM 3) PGDTQMN – (SEM 1) SUBJECT CODE & NAME QM0012- STATISTICAL PROCESS CONTROL AND PROCESS CAPABILITY SEMESTER 3 CREDITS 4 MARKS 60 Note: Answer all questions. Kindly note that answers for 10 marks questions should be approximately of 400 words. Each question is followed by evaluation scheme. 1 a. Explain the concept of Statistical Process Control. Answer : The concepts of Statistical Process Control (SPC) were initially developed by Dr. Walter Shewhart of Bell Laboratories in the 1920's, and were expanded upon by Dr. W. Edwards Deming, who introduced SPC to Japanese industry after WWII. After early successful adoption by Japanese firms,Statistical ProcessControl hasnow beenincorporated by organizations around the world as a primary tool to improve product quality by reducing process variation. Dr. Shewhart identified two sources of process variation: Chance variation that is inherent in process,andstable overtime,andAssignable,orUncontrolled variation,whichisunstable overtime - the result of specific events outside the system. Dr b. Describe the procedure to construct Fish bone diagram with an example. Explanation of SPC Procedure to construct Fish bone diagram Example Answer : Dr. Kaoru Ishikawa, a Japanese quality control statistician, invented the fishbone diagram. Therefore, it may be referred to as the Ishikawa diagram. The fishbone diagram is an analysis tool that provides a systematic way of looking at effects and the causes that create or contribute tothose effects.Because of the functionof the fishbonediagram, itmaybe referredto as

- 2. a cause-and-effect diagram. The design of the diagram looks much like the skeleton of a fish. Therefore, it is often referred to as the 2 Describe Deming’s Funnel experiment and Deming’s Red Bead experiment. Answer : Deming’s Funnel experiment The Funnel ExperimentwasdevisedbyDr.Demingtodescribe the adverse effectsof tamperingwith a processby makingchanges to it without first making a careful study of the possible causes of the variation in that process. In the experiment, a marble is dropped through a funnel onto a sheet of paper, which contains a target. The objective of the process is to get the marble to come to a stop as close to the target as possible. The experiment uses several methods to attempt to manipulate the funnel’s location to achieve the objective. 3 Differentiate between variable control charts and attribute control charts. Explain with an example how to calculate p Chart and np Chart. Differences Answer : Control Charts Statistical processcontrol wasdevelopedasafeedbacksystemthataidsinpreventingdefectsrather than allowingdefectstooccur.One elementof aprocesscontrol systemis control charts. Dr. Walter Shewhart defined the concept of common and special cause variation during the 1920s at Bell Laboratories. He developed a tool that he called the control chart, which could graphically depict variation.Thiscontrol chart,could also distinguish the two types of variation from each other, thus allowing for the elimination of special causes and the reduction of common cause variation. There are several typesof variablesdataand attributes data control charts. This section will discuss the different types of control charts, the 4 Explain Multivariate Control Charts and multivariate normal distribution. Answer : Multivariate control charts and Hotel ling’s T 2 statistic It is a fact of life that most data are naturally multivariate. Hostelling in 1947 introduced a statistic whichuniquelylendsitself toplottingmultivariate observations.This statistic, appropriately named Hotel ling’s T 2, is a scalar that combines information from the dispersion and mean of several variables. Due to the fact that computations are laborious and fairly complex and require some knowledge of matrix algebra, acceptance of multivariate control charts by industry was slow and hesitant. Multivariate control chartsnowmore accessible 5 a. Explain the concept of ProcessCapability.Give the Significance of Process Capability. Mention the major uses of Process capability Answer:The capabilityof aprocessis some measure of the proportionof in-specification items the process produces when it is in a state of statistical control. Processcapability isdifferentthanbatchperformance.Withbatchperformance,you are interested in what actually was produced. With process capability, you are interested in what the process is capable of producing when in statistical control

- 3. 6 Explain the methodology for Statistical Process Control (SPC) implementation. What are the benefits derived from SPC implementation? Answer : One way to improve a process is to implement a statistical process control program. Typically used in mass production, an SPC program enables a company to continually release a productthrough the use of control charts ratherthan inspectingindividual lots of a product. As long as a device companymaintainsmeticulouslyreviewedandsigneddocumentationof its process, and the processis withinspecification,FDA will allowproductreleaseusingSPC.This will reduce time to market by eliminating interruptions in production. SPC enables a company to detect trends and defects earlier in production, thereby reducing inspection, rework, and scrap costs. SPC is usually represented by a control chart, which is a Dear students get fully solved assignments Send your semester & Specialization name to our mail id : “ help.mbaassignments@gmail.com ” or Call us at : 08263069601 (Prefer mailing. Call in emergency )