Air conditioning gauge diagnostics - Boston Auto Repair

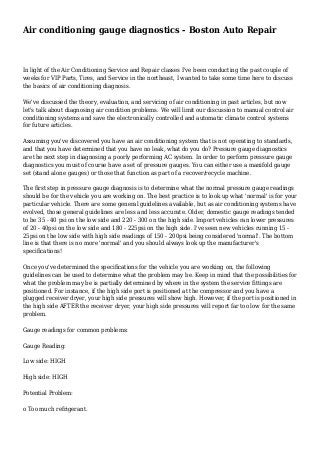

- 1. Air conditioning gauge diagnostics - Boston Auto Repair In light of the Air Conditioning Service and Repair classes I've been conducting the past couple of weeks for VIP Parts, Tires, and Service in the northeast, I wanted to take some time here to discuss the basics of air conditioning diagnosis. We've discussed the theory, evaluation, and servicing of air conditioning in past articles, but now let's talk about diagnosing air condition problems. We will limit our discussion to manual control air conditioning systems and save the electronically controlled and automatic climate control systems for future articles. Assuming you've discovered you have an air conditioning system that is not operating to standards, and that you have determined that you have no leak, what do you do? Pressure gauge diagnostics are the next step in diagnosing a poorly performing AC system. In order to perform pressure gauge diagnostics you must of course have a set of pressure gauges. You can either use a manifold gauge set (stand alone gauges) or those that function as part of a recover/recycle machine. The first step in pressure gauge diagnosis is to determine what the normal pressure gauge readings should be for the vehicle you are working on. The best practice is to look up what 'normal' is for your particular vehicle. There are some general guidelines available, but as air conditioning systems have evolved, those general guidelines are less and less accurate. Older, domestic gauge readings tended to be 35 - 40 psi on the low side and 220 - 300 on the high side. Import vehicles ran lower pressures of 20 - 40psi on the low side and 180 - 225psi on the high side. I've seen new vehicles running 15 - 25psi on the low side with high side readings of 150 - 200psi being considered 'normal'. The bottom line is that there is no more 'normal' and you should always look up the manufacturer's specifications! Once you've determined the specifications for the vehicle you are working on, the following guidelines can be used to determine what the problem may be. Keep in mind that the possibilities for what the problem may be is partially determined by where in the system the service fittings are positioned. For instance, if the high side port is positioned at the compressor and you have a plugged receiver dryer, your high side pressures will show high. However, if the port is positioned in the high side AFTER the receiver dryer, your high side pressures will report far too low for the same problem. Gauge readings for common problems: Gauge Reading: Low side: HIGH High side: HIGH Potential Problem: o Too much refrigerant.

- 2. o Poor condenser airflow. o Non-condensable gases (air) in the system. o Moisture in the system. Gauge Reading: Low side: LOW High side: LOW Potential Problem: o Not enough refrigerant. o Compressor problem. Gauge Reading: Low side: LOW High side: HIGH Potential Problem: o Expansion valve plugged o Orifice tube plugged o Restriction in screen (receiver dryer) Gauge Reading: Low side: HIGH High side: LOW Potential Problem: o Compressor valve problem. o Missing orifice tube. Gauge Reading: Low side: Vacuum High side: HIGH Potential Problem:

- 3. o Low side restriction o Plugged orifice tube o Plugged expansion valve o Moisture in the system Once you've determined what your problem most likely is, then it's time to resolve the issue. If it's a case of too much refrigerant you will need to recover and recycle the refrigerant charge and then recharge the system with the proper amount of refrigerant. The system requirement can be found on the AC sticker under the hood, or in your service information database. If the suspected problem is a blockage, not only will you need to replace the blocked component, but you will need to identify the root cause of the blockage. Did another component fail causing the blockage? Was it moisture? If so, why? If the problem was a compressor, why did the compressor fail? Not enough refrigerant oil? Too much oil? Don't just stop your diagnosis at what the problem is. Find the root cause of the failure. No matter what component you replace, remember, you MUST replace the component that contains the desiccant material whether it's the receiver dryer, accumulator, or a separate desiccant bag located in the condenser. Not doing so will result in future failure of the system. Many companies that supply compressors will no longer warranty their product if these other components are not replaced during the repair. As always I can be reached for questions, comments, or criticism at www.intelligentmechanic.com. Suggestions for future articles are always welcome as well. Until next time, keep up the good work and never stop learning!