Vibration Control Of Exposure

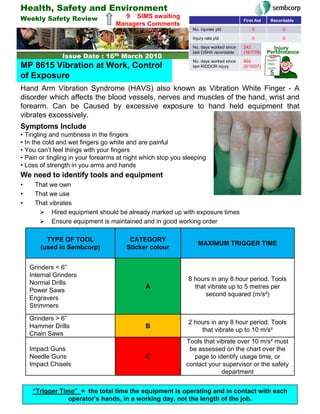

- 1. Health, Safety and Environment Weekly Safety Review 9 SIMS awaiting First Aid Recordable Managers Comments No. injuries ytd 5 0 Injury rate ytd 0 0 No. days worked since 242 Injury last OSHA recordable (16/7/09) Performance Issue Date : 16 th March 2010 INJURY No. days worked since 894 MP 8615 Vibration at Work, Control last RIDDOR injury (5/10/07) FREE WEEK 5 of Exposure Hand Arm Vibration Syndrome (HAVS) also known as Vibration White Finger - A disorder which affects the blood vessels, nerves and muscles of the hand, wrist and forearm. Can be Caused by excessive exposure to hand held equipment that vibrates excessively. Symptoms Include • Tingling and numbness in the fingers • In the cold and wet fingers go white and are painful • You can’t feel things with your fingers • Pain or tingling in your forearms at night which stop you sleeping • Loss of strength in you arms and hands We need to identify tools and equipment • That we own • That we use • That vibrates Hired equipment should be already marked up with exposure times Ensure equipment is maintained and in good working order TYPE OF TOOL CATEGORY MAXIMUM TRIGGER TIME (used in Sembcorp) Sticker colour Grinders < 6” Internal Grinders 8 hours in any 8 hour period. Tools Normal Drills A that vibrate up to 5 metres per Power Saws second squared (m/s²) Engravers Strimmers Grinders > 6” 2 hours in any 8 hour period. Tools Hammer Drills B that vibrate up to 10 m/s² Chain Saws Tools that vibrate over 10 m/s² must Impact Guns be assessed on the chart over the Needle Guns C page to identify usage time, or Impact Chisels contact your supervisor or the safety department “Trigger Time” = the total time the equipment is operating and in contact with each operator’s hands, in a working day, not the length of the job.

- 2. The procedure requires each work group to……. •Identify all the vibrating tools in their area and put them in a register • Assess the level of vibration each tool produces • Place the correct coloured sticker on the equipment Contact the safety department to help carry out your survey What can you do ……. Let your supervisor know if you have any symptoms Learn to Recognise the signs of HAVS Use any control measures provided Try a different approach to your job Use the right tool for the job Keep blades and cutting edges sharp Keep machines maintained Intersperse vibrating activities and other work Improve your blood circulation by: – Keeping warm, wear gloves etc. – Giving up smoking – Massaging and exercising fingers during work breaks