Brief Overview of my Research

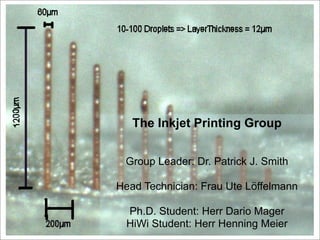

- 1. The Inkjet Printing Group Group Leader: Dr. Patrick J. Smith Head Technician: Frau Ute Löffelmann Ph.D. Student: Herr Dario Mager HiWi Student: Herr Henning Meier Date of last update: January 27th 2009

- 2. Inkjet Printing – What you want, Where you want, When you want The research of the laboratory of inkjet printing is interested in using piezo-electric drop-on-demand inkjet printing as a dispensing tool for the deposition of a wide range of materials. These materials are organic, inorganic or biological. The main advantage of piezo-electric inkjet printing is that it is able to deliver precise amounts of material to a pre-determined position on a substrate. The laboratory is interested in using inkjet printing as a low-cost, rapid manufacturing technique; either to use inkjet printing to produce masks, to produce “maskless” features, tapes or three dimensional structures. Narrow features, rapid and low-cost fabrication The laboratory is also interested in using inkjet printing in conjunction with other patterning techniques such as micro-contact printing, which uses stamps and patterned blocks to obtain exceptionally small features. Here the surface energy of a substrate is modified by the application of a non-wetting layer. Nano-embossing, MIMIC and soft lithography have also been used to obtain features that are 20 microns or thinner. Surface Science – The substrate is not passive All substrates have associated surface energies, which have a direct effect on features that are printed onto them. Of current interest is the ‘coffee stain’ effect, which is the phenomenon whereby suspended material preferentially deposits at the boundary of a drying droplet. Obviously, when one is using a liquid-handling approach, such as inkjet printing, for feature formation one must understand how the as-printed liquid behaves upon a substrate in order to obtain the desired shape. Date of last update: January 27th 2009

- 3. Publications 2009 Chapter: “The Behaviour of an Ink Droplet on the Substrate,” PJ Smith, ‘The Chemistry Behind Inkjet Inks and Digital Printing’ Ed: Prof’ Shlomo Magdassi, World Scientific Publishing, Singapore, Spring 2009. 2008 “Inkjet printing as a deposition and patterning tool for polymers and inorganic particles” E Tekin, PJ Smith and US Schubert Soft Matter, 2008, 4, 703 “‘Invisible’ silver tracks produced by combining hot-embossing and inkjet printing” C Hendriks, PJ Smith, J Perelaer, AMJ v.d. Berg, and US Schubert Advanced Functional Materials, 2008, 18, 1031 “The preferential deposition of silica micro-particles at the boundary of inkjet printed droplets” J Perelaer, PJ Smith, C Hendriks, AMJ v.d.Berg and US Schubert Soft Matter, 2008, 4, 1072 “Theoretical investigation of the influence of nozzle diameter variation on the fabrication of TFT LCD colour filters,” D-Y Shin and PJ Smith Journal of Applied Physics, 2008, 103, 114905 “Inkjet printing of structures for MRI Coils,” D Mager, U Löffelmann, PJ Smith, A Peter, L del Tin and JG Korvink, Proceedings of Digital Fabrication 2008 “Inkjet printing silver-containing inks,” PJ Smith, D Mager, U Löffelmann, JG Korvink, Proceedings of Digital Fabrication 2008 Date of last update: January 27th 2009

- 4. Publications 2007 “Inkjet printing of luminescent CdTe nanocrystal/polymer composites E Tekin, PJ Smith, S Hoeppener, AMJ van den Berg, AS Susha, J Feldman, AL Rogach and US Schubert, Advanced Functional Materials, 2007, 17, 23 “Inkjet printing of polyurethane colloidal suspensions” AMJ v.d.Berg, PJ Smith, J Perelaer and US Schubert, Soft Matter 2007, 3, 238 “Geometric Control of Inkjet Printed Features Using a Gelating Polymer” AMJ v.d.Berg, AWM de Laat, PJ Smith, J Perelaer and US Schubert, Journal of Materials Chemistry 2007, 17, 677 “Phase Change Rapid Prototyping with Aqueous Inks” D Mager, PJ Smith and JG Korvink, Proceedings of Digital Fabrication 2007, 908 2006 “Direct Ink-jet Printing and Low Temperature Conversion of Conductive Silver Patterns” PJ Smith, D-Y Shin, N Reis, J Stringer and B Derby; Journal of Materials Science. 2006, 41, 4153 2005 “A low curing temperature silver ink for use in ink-jet printing and subsequent production of conductive tracks” AL Dearden, PJ Smith, D-Y Shin, N Reis, B Derby and P O’Brien; Macromol. Rapid Commun., 2005, 26, 315 Date of last update: January 27th 2009

- 5. Publications in Preparation “Droplet Tailoring Using Evaporative Inkjet Printing” J Perelaer, PJ Smith, MMP Wijnen, E v.d.Bosch, R Eckardt, PHJM Ketelaars and US Schubert Macromolecular Chemistry and Physics, Accepted “The Spreading of Inkjet Printed Droplets with a Varied Polymer’s Molecular Weight on a Dry Solid Substrate” J Perelaer, PJ Smith, E v.d.Bosch, SSC van Grootel, PHJM Ketelaars and US Schubert Macromolecular Chemistry and Physics, Accepted “Room Temperature Preparation of Conductive Silver Features using Spin-coating and Inkjet Printing” JJP Valeton, K Hermans, CWM Bastiaansen, DJ Broer, J Perelaer, US Schubert, GP Crawford and PJ Smith Advanced Materials, to be submitted (February 2009) “Inkjet Printed, Conductiver, 25 mm Wide Silver Tracks on Unstructured Polyimide,” H. Meier, U Löffelmann, D Mager, PJ Smith, JG Korvink Advanced Materials, Submitted (December 2008) “An MRI Receiver Coil Produced Directly by Inkjet Printing” D Mager, U Löffelmann, PJ Smith, JG Korvink Advanced Functional Materials, to be submitted (February 2009) “Inkjet Printing of Proteins,” JT Delaney, PJ Smith and US Schubert, In preparation Date of last update: January 27th 2009