Laminated Object Manufacturing (LOM)

•Download as DOCX, PDF•

2 likes•3,674 views

Report

Share

Report

Share

Recommended

Recommended

31 ĐỀ THI THỬ VÀO LỚP 10 - TIẾNG ANH - FORM MỚI 2025 - 40 CÂU HỎI - BÙI VĂN V...

31 ĐỀ THI THỬ VÀO LỚP 10 - TIẾNG ANH - FORM MỚI 2025 - 40 CÂU HỎI - BÙI VĂN V...Nguyen Thanh Tu Collection

More Related Content

More from Suhaimi Alhakimi

More from Suhaimi Alhakimi (17)

Recently uploaded

31 ĐỀ THI THỬ VÀO LỚP 10 - TIẾNG ANH - FORM MỚI 2025 - 40 CÂU HỎI - BÙI VĂN V...

31 ĐỀ THI THỬ VÀO LỚP 10 - TIẾNG ANH - FORM MỚI 2025 - 40 CÂU HỎI - BÙI VĂN V...Nguyen Thanh Tu Collection

Faculty Profile prashantha K EEE dept Sri Sairam college of Engineering

Faculty Profile prashantha K EEE dept Sri Sairam college of EngineeringSri Sairam College Of Engineering Bengaluru

Team Lead Succeed – Helping you and your team achieve high-performance teamwo...

Team Lead Succeed – Helping you and your team achieve high-performance teamwo...Association for Project Management

Recently uploaded (20)

31 ĐỀ THI THỬ VÀO LỚP 10 - TIẾNG ANH - FORM MỚI 2025 - 40 CÂU HỎI - BÙI VĂN V...

31 ĐỀ THI THỬ VÀO LỚP 10 - TIẾNG ANH - FORM MỚI 2025 - 40 CÂU HỎI - BÙI VĂN V...

Oppenheimer Film Discussion for Philosophy and Film

Oppenheimer Film Discussion for Philosophy and Film

Using Grammatical Signals Suitable to Patterns of Idea Development

Using Grammatical Signals Suitable to Patterns of Idea Development

Student Profile Sample - We help schools to connect the data they have, with ...

Student Profile Sample - We help schools to connect the data they have, with ...

Faculty Profile prashantha K EEE dept Sri Sairam college of Engineering

Faculty Profile prashantha K EEE dept Sri Sairam college of Engineering

4.16.24 21st Century Movements for Black Lives.pptx

4.16.24 21st Century Movements for Black Lives.pptx

Transaction Management in Database Management System

Transaction Management in Database Management System

Team Lead Succeed – Helping you and your team achieve high-performance teamwo...

Team Lead Succeed – Helping you and your team achieve high-performance teamwo...

Beauty Amidst the Bytes_ Unearthing Unexpected Advantages of the Digital Wast...

Beauty Amidst the Bytes_ Unearthing Unexpected Advantages of the Digital Wast...

MS4 level being good citizen -imperative- (1) (1).pdf

MS4 level being good citizen -imperative- (1) (1).pdf

Laminated Object Manufacturing (LOM)

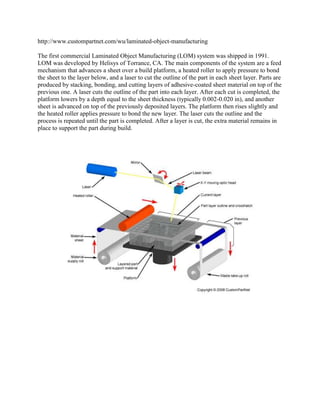

- 1. http://www.custompartnet.com/wu/laminated-object-manufacturing The first commercial Laminated Object Manufacturing (LOM) system was shipped in 1991. LOM was developed by Helisys of Torrance, CA. The main components of the system are a feed mechanism that advances a sheet over a build platform, a heated roller to apply pressure to bond the sheet to the layer below, and a laser to cut the outline of the part in each sheet layer. Parts are produced by stacking, bonding, and cutting layers of adhesive-coated sheet material on top of the previous one. A laser cuts the outline of the part into each layer. After each cut is completed, the platform lowers by a depth equal to the sheet thickness (typically 0.002-0.020 in), and another sheet is advanced on top of the previously deposited layers. The platform then rises slightly and the heated roller applies pressure to bond the new layer. The laser cuts the outline and the process is repeated until the part is completed. After a layer is cut, the extra material remains in place to support the part during build.